Gravity spool filler and method for gravity filling beverages

A technology for fillers, beverages, applied in the direction of transportation and packaging, packaging, bottle filling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

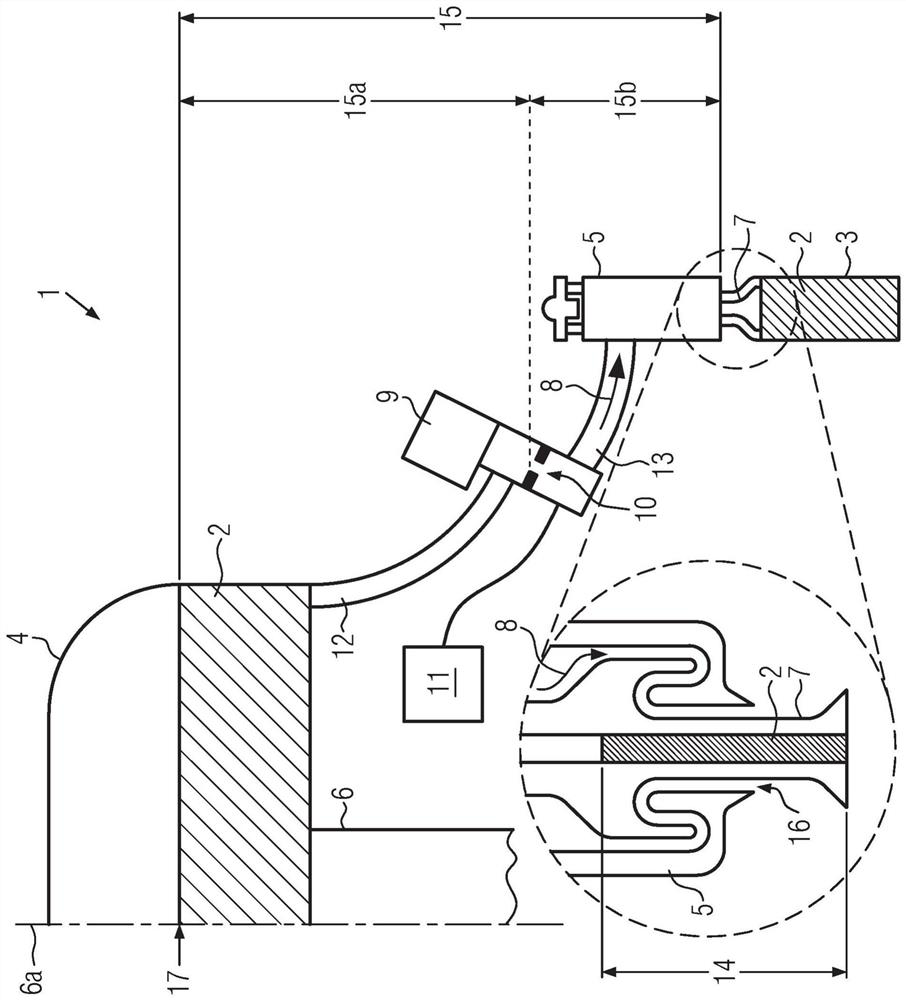

[0028] like figure 1 As can be seen in a schematic partial view, a gravity spool filler 1 for filling beverages 2, such as spirits, wine or similar liquid products into bottles 3 comprises a product pot 4 and a plurality of The filling valve 5 (only one of which is shown) can be opened and closed in a known manner by squeezing and removing the bottle 3 .

[0029] Gravity spool filler 1 is preferably of the circumferential type, so that product pot 4 , which can also be configured as an annular pot (not shown), for example, and filling valve 5 are arranged on the rotor of filler turret 6 . this is in figure 1 is illustrated schematically by the axis of rotation 6a.

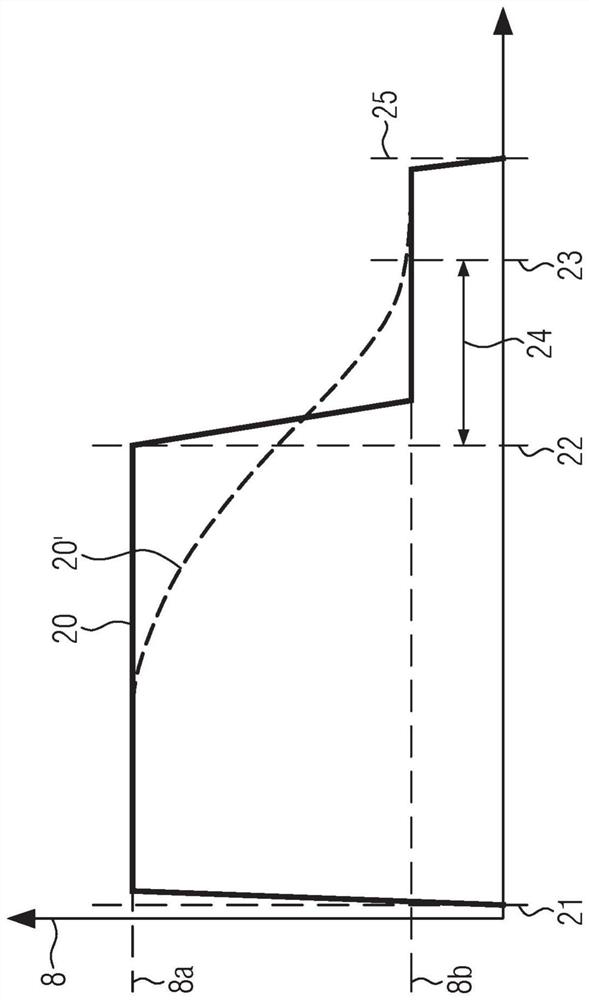

[0030] If especially from figure 1 As can be seen in the enlarged section in , the filling valve 5 comprises a return gas pipe 7 which is hermetically closed by the raised beverage 2 at the end of the respective filling process, whereby the beverage flows into 8 (product). inflow) slowly stopped.

[0031] In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com