Hot-line work wire clamp capable of being rapidly lapped

A technology of live work and wire clips, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high labor intensity, long operation time of insulating operating rod and rotating screw rod, and high physical strength requirements, so as to reduce labor intensity and reduce large-scale power outages The risks and economic benefits are obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

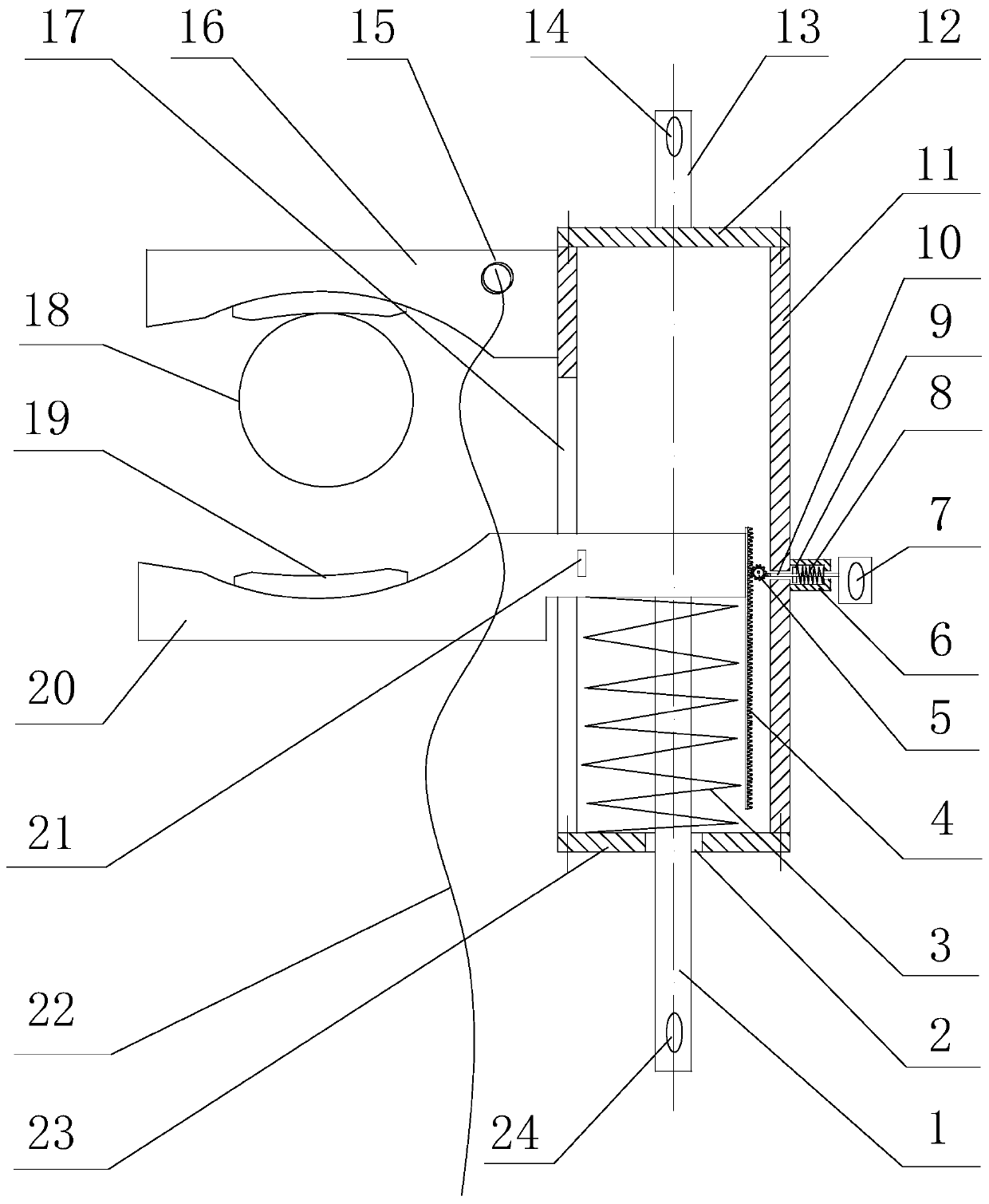

[0017] Such as figure 1 As shown in the figure, a live work line clamp for quick pick-up includes a reset pull rod 1, a first compression spring 3, a spur rack 4, a gear 5, a cavity 11, an upper cover plate 12, a hanging rod 13, and a fixed line clamp block 16. Movable line clamp block 20, limit block 21, bottom cover plate 23, latch lock mechanism; cavity (or cylinder, which can be square, circular or other shapes) 11 is a through hole in the vertical direction, and the cavity The left side lower part of 11 is vertically provided with track hole (or claiming chute hole) 17 ( figure 1 The left side is left, the right side is right), the track hole 17 communicates with the through hole of the cavity, the upper cover plate 12 is located on the upper end surface of the cavity 11, and the upper cover plate 12 is fixedly connected with the cavity 11 by screws, and the upper The cover plate 12 is fixed with a hanging rod 13, and the hanging rod 13 is provided with a hanging hole 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com