Stuffing mixer applied to meat buns

A stuffing machine and meat bun technology, which is applied in the field of food processing, can solve the problems of high stickiness of meat stuffing, low work efficiency, and difficult cleaning of minced meat, and achieve the effects of improving the taste, hygiene and eating experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

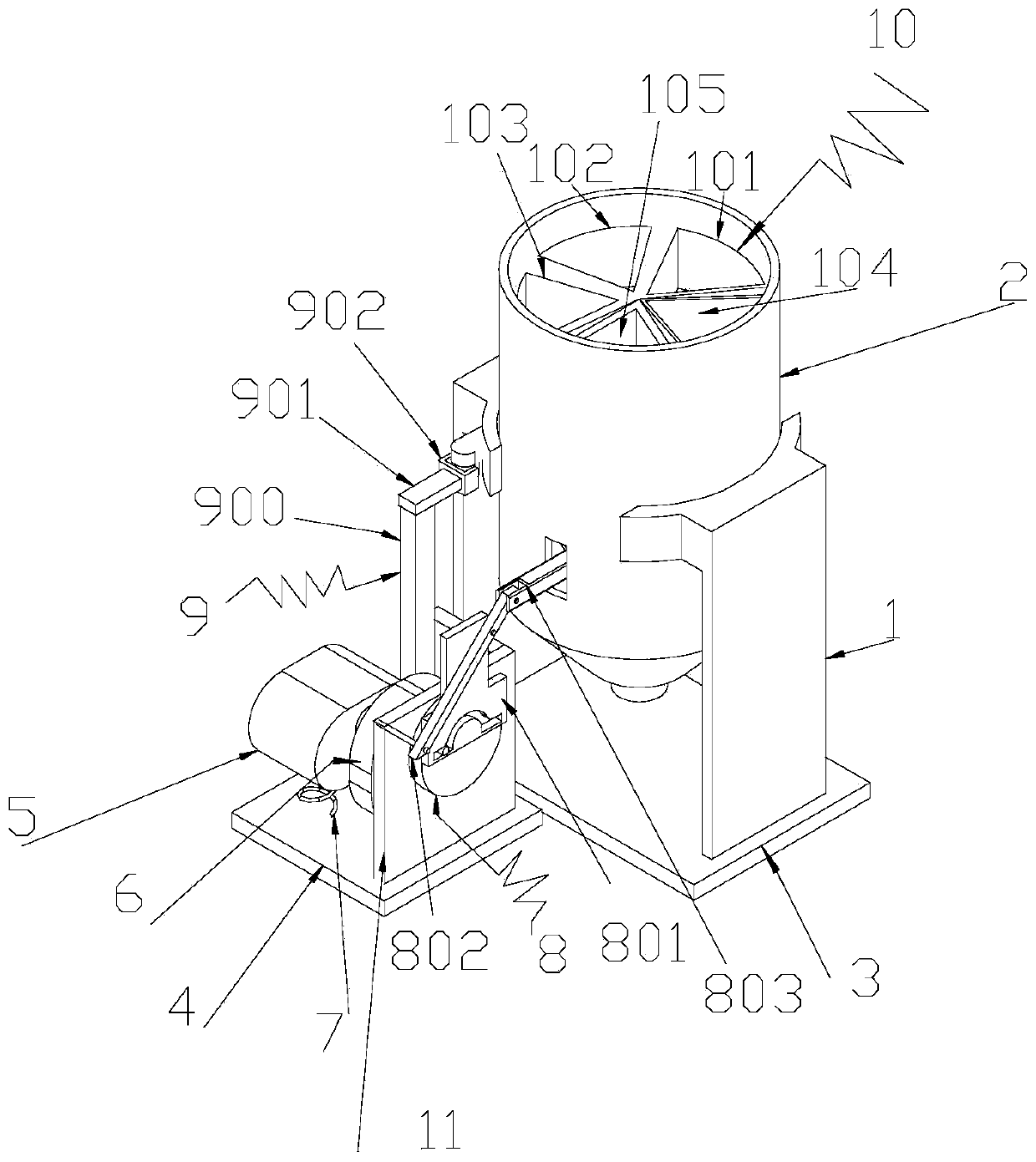

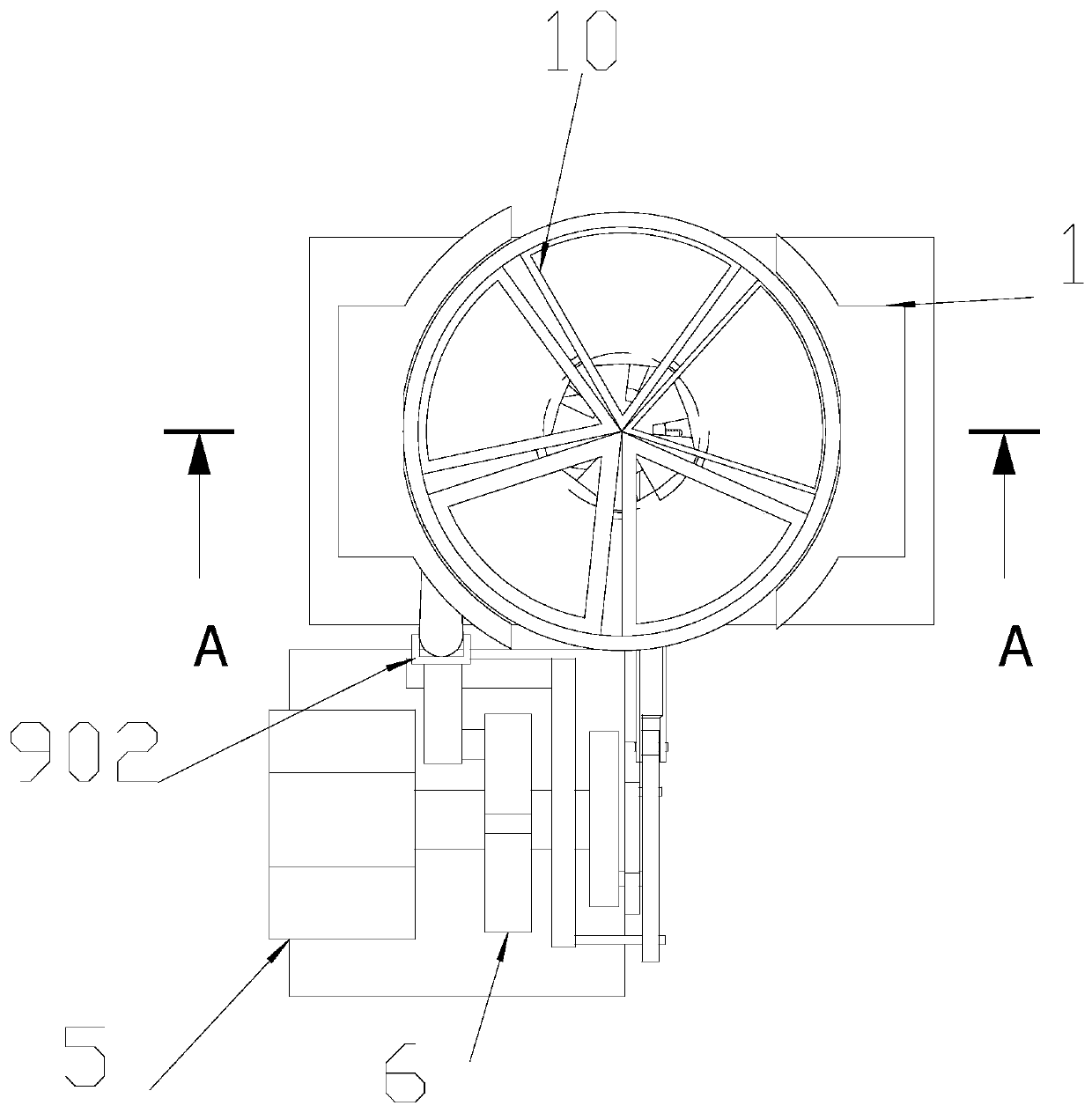

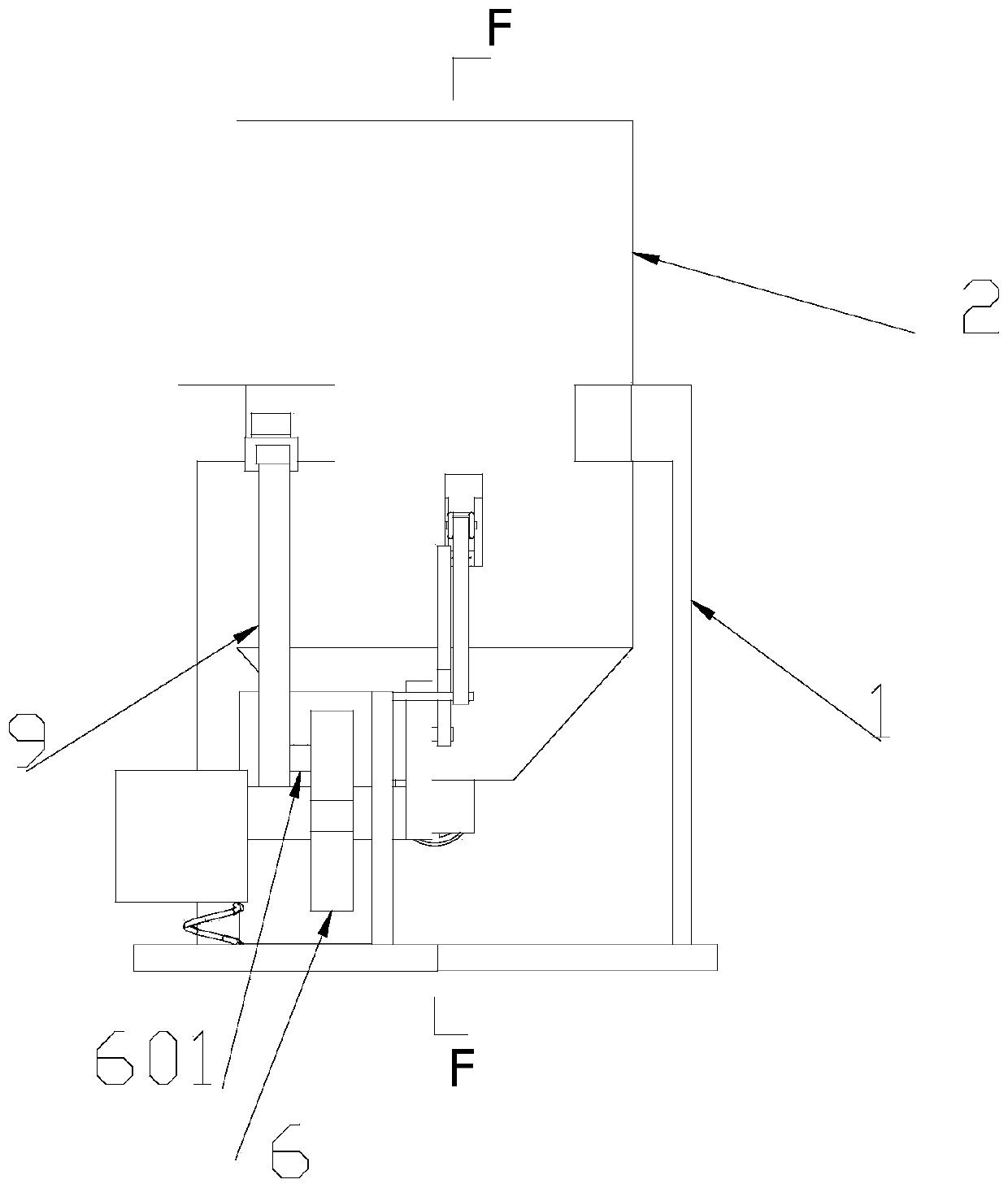

[0022] Such as Figure 1-9 The shown stuffing machine for meat buns includes a working cavity 2, five ingredient boxes 10 arranged at the upper end of the working cavity 2, a connecting plate 12 arranged at the lower end of the ingredient box 10, and The batching baffle 106 at the lower end of the connecting plate, the reciprocating rotating part 9 movably connected to the batching baffle 101, the driving motor 5 arranged at the lower end of the reciprocating rotating part 9, and the front end of the driving motor 5 The universal joint 6, the vertical reciprocating transmission part 8 arranged at the front end of the universal joint, the support rod 15 movably connected with the vertical reciprocating transmission part 8, and the support rod 15 is arranged at the The elastic reset member 16 of the vertical reciprocating transmission member 8, the side flap 17 symmetrically arranged at the lower end of the vertical reciprocating transmission member 8, and the delivery member sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com