A kind of composite non-precious metal denitration catalyst and preparation method thereof

A denitrification catalyst and non-precious metal technology, which is applied in the field of composite non-precious metal denitrification catalyst and its preparation, can solve the problems of unsatisfactory catalytic efficiency, poor environmental protection, toxicity or pollution, etc., and achieve stable performance and wear resistance of the film layer Good performance and corrosion resistance, the effect of reducing toxic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

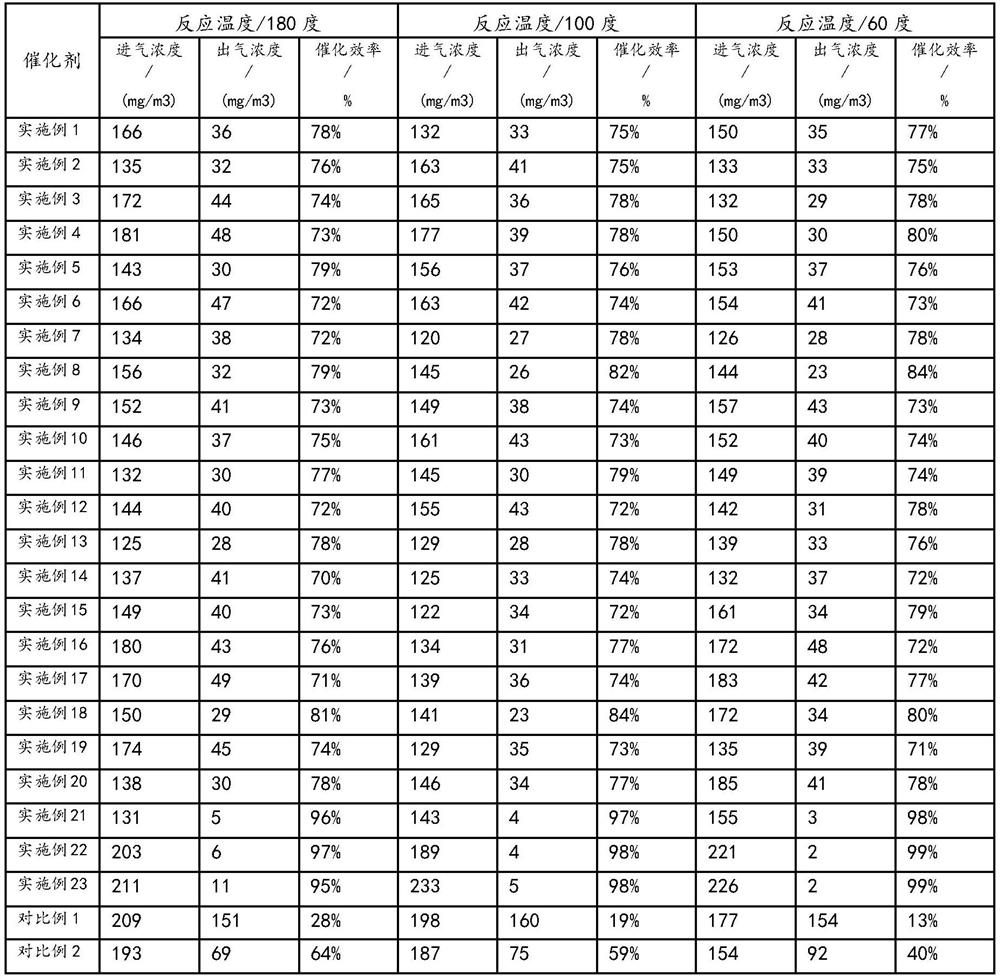

Examples

Embodiment 1

[0026] A layer of catalyst layer is vapor-deposited on the zeolite by a vacuum coating machine, and the catalyst layer is Ti0 2 , which can be monocrystalline Ti0 2 , it can also be a mixed oxide in which multiple crystal forms coexist, such as rutile Ti0 2 and anatase Ti0 2 Mixing, in this embodiment, the catalyst layer is rutile Ti0 2 and anatase Ti0 2 mixed oxides, the thickness of which is 10nm; the parameters of evaporation conditions in the above process are as follows: the vacuum degree of the vacuum chamber is 4.9*10 -3Pa, the temperature of the vacuum chamber is 200 degrees, the gas used is argon, the target material parameters: Ti0 2 Target material, 1mm particles, density 80%, purity 99.95%, electron gun current set to 100mA, deposition rate controlled at According to the XRD standard card comparison, after evaporation, the rutile TiO 2 :Anatase TiO 2 =6.1:1.0 (Wt%).

[0027] It should be noted that, in this embodiment, the zeolite is a Y-type zeolite molec...

Embodiment 2

[0029] Evaporate a catalyst layer on the electrospun nanofiber by vacuum coating machine, the catalyst layer is V 2 o 5 , with a thickness of 7nm; the parameters of evaporation conditions in the above process are as follows: the vacuum degree of the vacuum chamber is 4*10 -3 Pa, the temperature of the vacuum chamber is 250 degrees, the gas used is nitrogen, the target material parameters: V 2 o 5 Target material, 2mm particles, density 62%, purity 99.96%, electron gun current set to 200mA, deposition rate controlled at

[0030] In this embodiment, the electrospun nanofibers are nylon 6 electrospun nanofibers, and the BET specific surface area is 133 mg / m 3 .

Embodiment 3

[0032] A catalyst layer is vapor-deposited on the glass fiber by a vacuum coating machine, and the catalyst layer is Cr 2 o 3 , with a thickness of 5nm; the parameters of evaporation conditions in the above process are as follows: the vacuum degree of the vacuum chamber is 3*10 -3 Pa, the temperature of the vacuum chamber is 300 degrees, the gas used is argon, the target parameter: Cr 2 o 3 Target material, 3mm particles, density 82%, purity 99.95%, electron gun current set to 300mA, deposition rate controlled at

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com