A sorting system for solar cells capable of continuous adsorption

A technology of solar cells and sorting systems, applied in the directions of sorting, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of complex production and processing technology, difficult assembly, high cost, etc., and achieve simple processing and assembly process , Improve the adsorption effect and avoid the effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

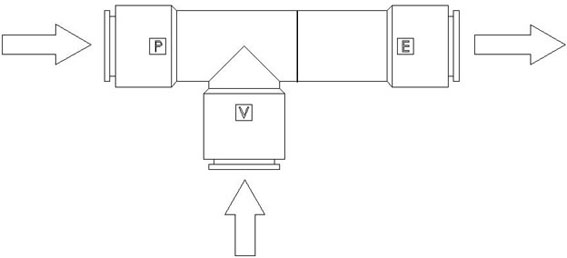

[0031] The principle of vacuum generator 9 is as follows figure 1 As shown in the figure, the P port is the air inlet, the E port is the exhaust port, and the V port is the exhaust port. The working principle is that the high-speed airflow enters the vacuum generator 9 through the P port. Due to the internal structure of the vacuum generator, the high-speed airflow will be At the same time, the E port will be exhausted and the V port will be pumped, so that the V port will form a certain negative pressure.

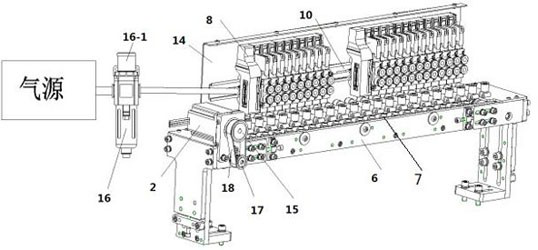

[0032] like figure 2 As shown, the present invention includes a frame 1 and a control mechanism, a conveying mechanism and a vacuum forming pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com