Production device of filter line plate for X-ray machine

A production device and filter plate technology, applied in the field of medical imaging, can solve the problems of low resolution and resolution of film images, misdiagnosis, thinning of filter grids, etc., and achieve the effect of improving resolution and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

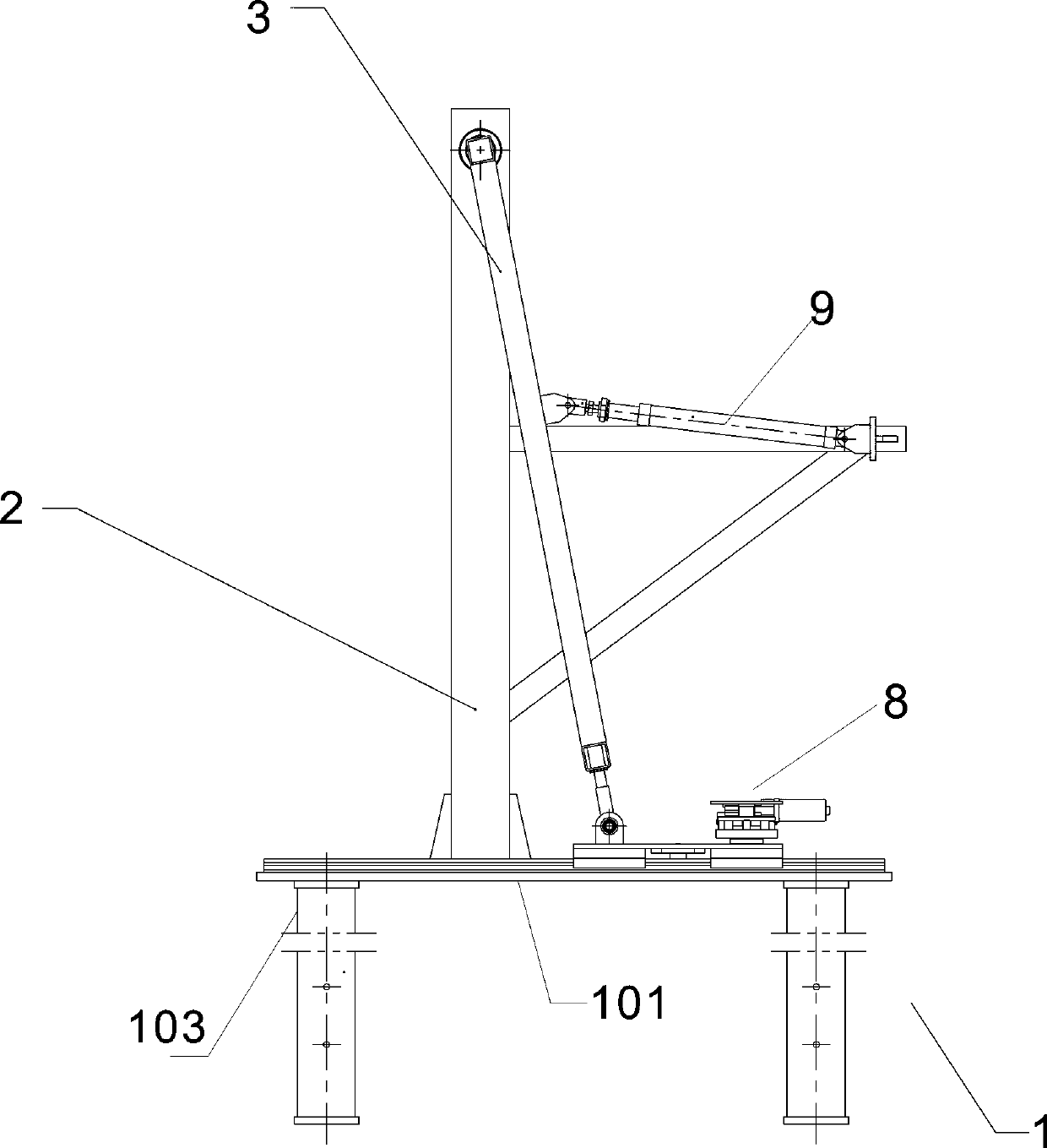

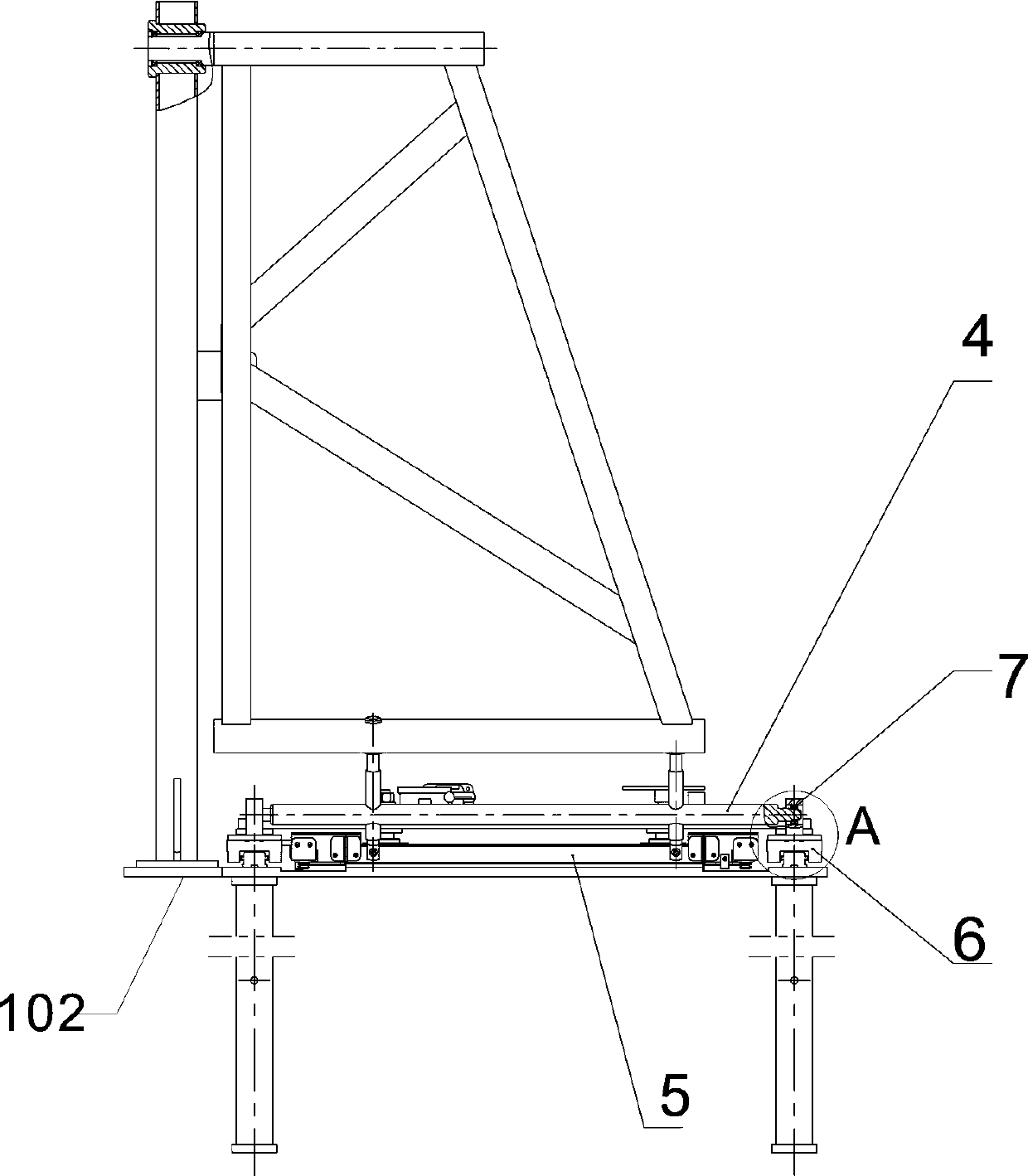

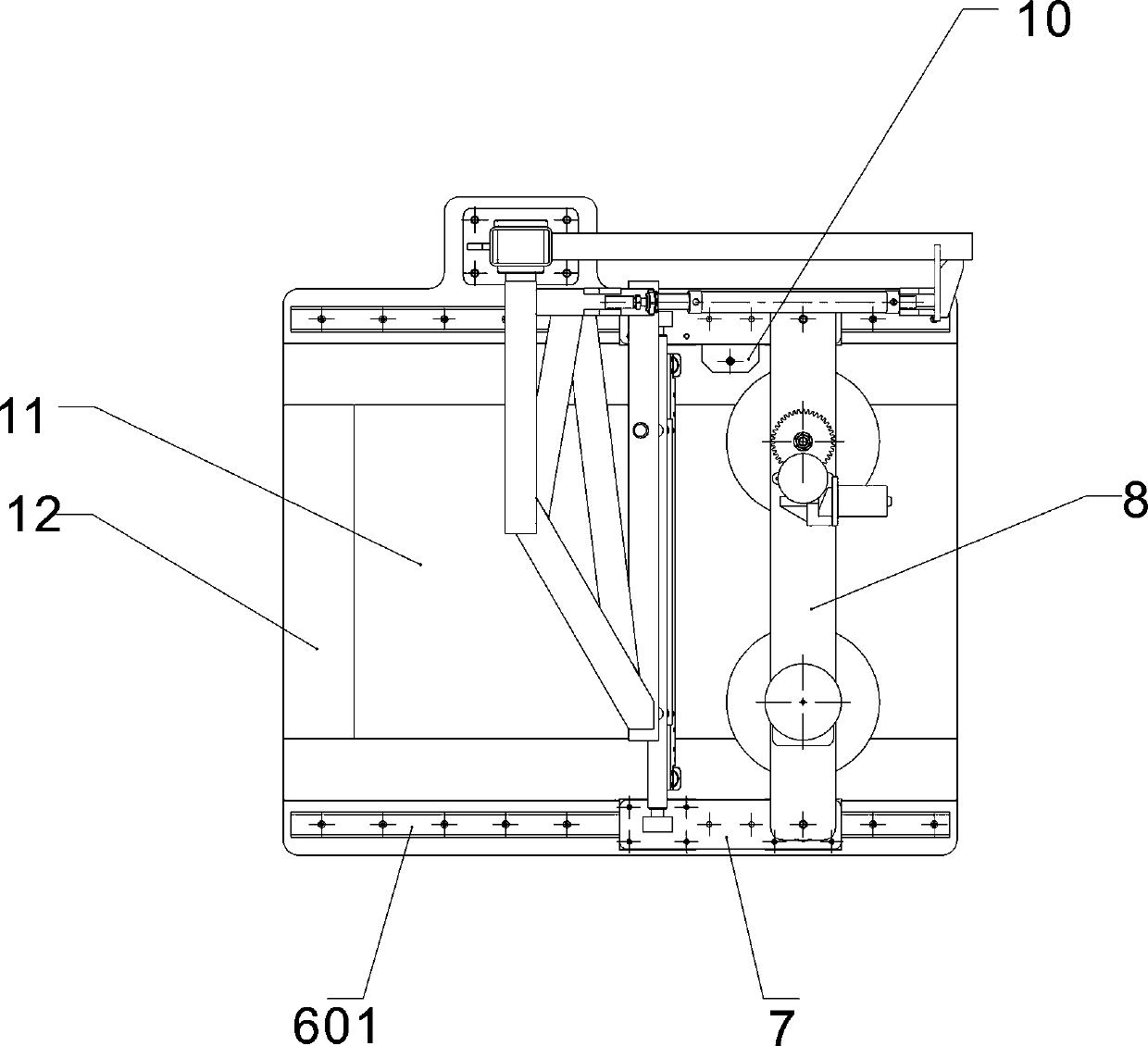

[0050] combined with figure 2 , 3 , 4, 10 and 11 described a kind of production device of X-ray machine filter plate, comprises workbench 1, and workbench 1 comprises support leg 103, is table top 101 on the support leg 103, and the side of table top 101 is provided with extension Part 102, the workbench 1 is provided with a stand 2, the upper part of the stand 2 and the swing frame 3 are connected by a bearing, and the middle part is connected by a cylinder 9, and the swing frame 3 is driven by the cylinder 9, and the stand 2 and the swing frame can be The bearing connection part of 3 is the center of the circle and performs pendulum motion. Both sides of the upper surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com