Method of making motion picture release-print film

a technology of releaseprint and motion picture, applied in the field of motion picture film, can solve the problems of anamorphic process, relatively expensive process, and audience dislike of the seams between the three, and achieve the effect of enhancing the projected image, and reducing the waste of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

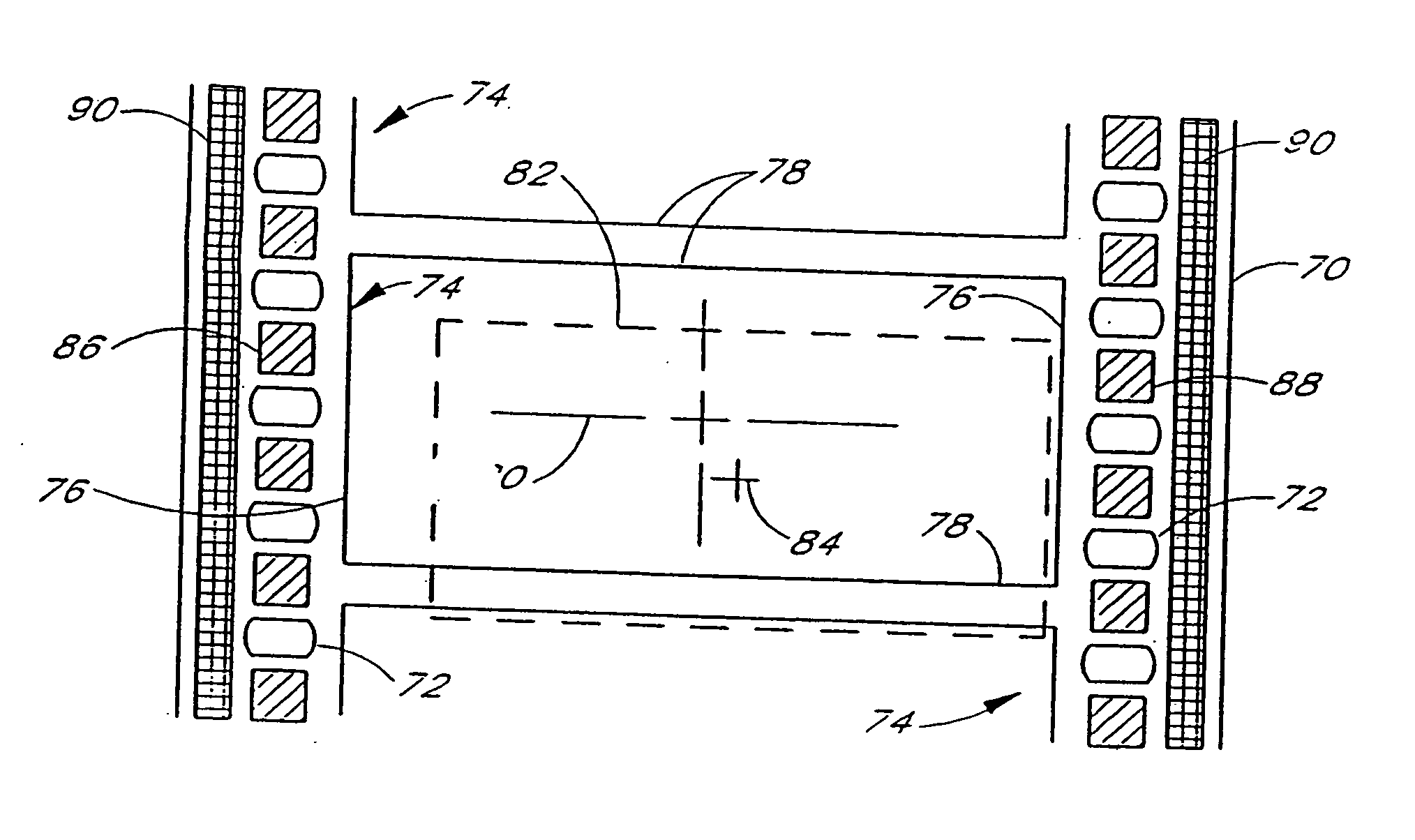

[0031] The first embodiment of the present invention, which is referred to as “MaxiVision,” is shown in FIG. 3. It comprises a strip of 35 mm motion picture film 70 having its entire surface coated with a light sensitive emulsion. Two rows of perforations 72 extend along opposite edges of the film for engagement with the sprockets of a film projection system. Images are exposed onto the film, with the images being defined by a series of frames 74 having a significantly enlarged size.

[0032] In accordance with the invention, the height 76 of each frame 74 spans three perforations 72. This eliminates the wasted area between frames that currently exists in the 1.85:1 / four-perforation projection format, as previously described in conjunction with FIG. 2a. As a result, the print film consumption and processing costs for MaxiVision are reduced by 25%, without sacrificing image size in any way. Furthermore, an increase in projectable image size is achieved by allowing the permissible image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com