Synchronous adjusting device for multiple spacing and angles and implementation method of synchronous adjusting device

A synchronous adjustment and angle technology, applied in the field of multi-spacing angle synchronous adjustment devices, can solve problems such as inability to rotate, and achieve the effect of ensuring accuracy, improving efficiency and range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

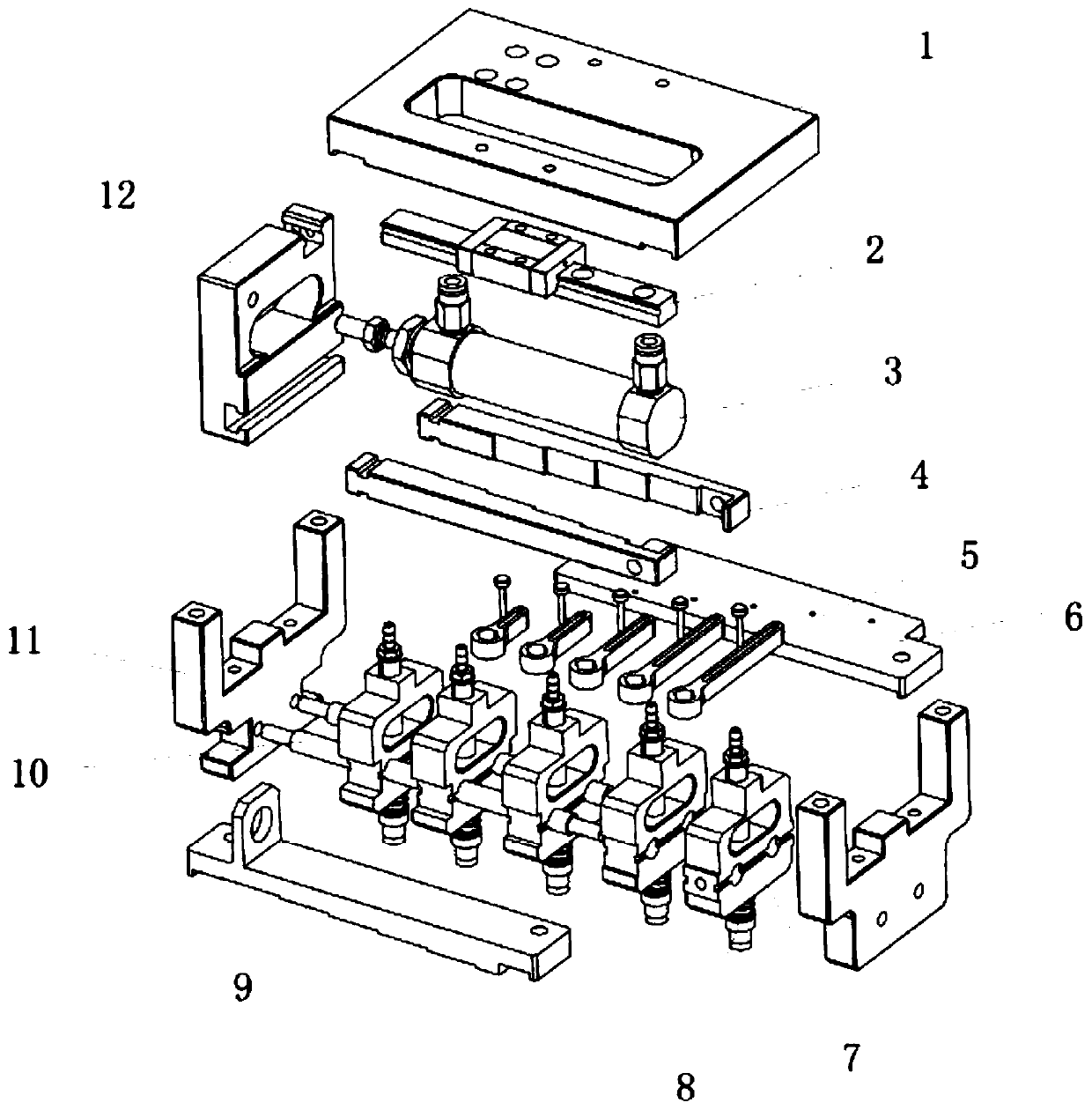

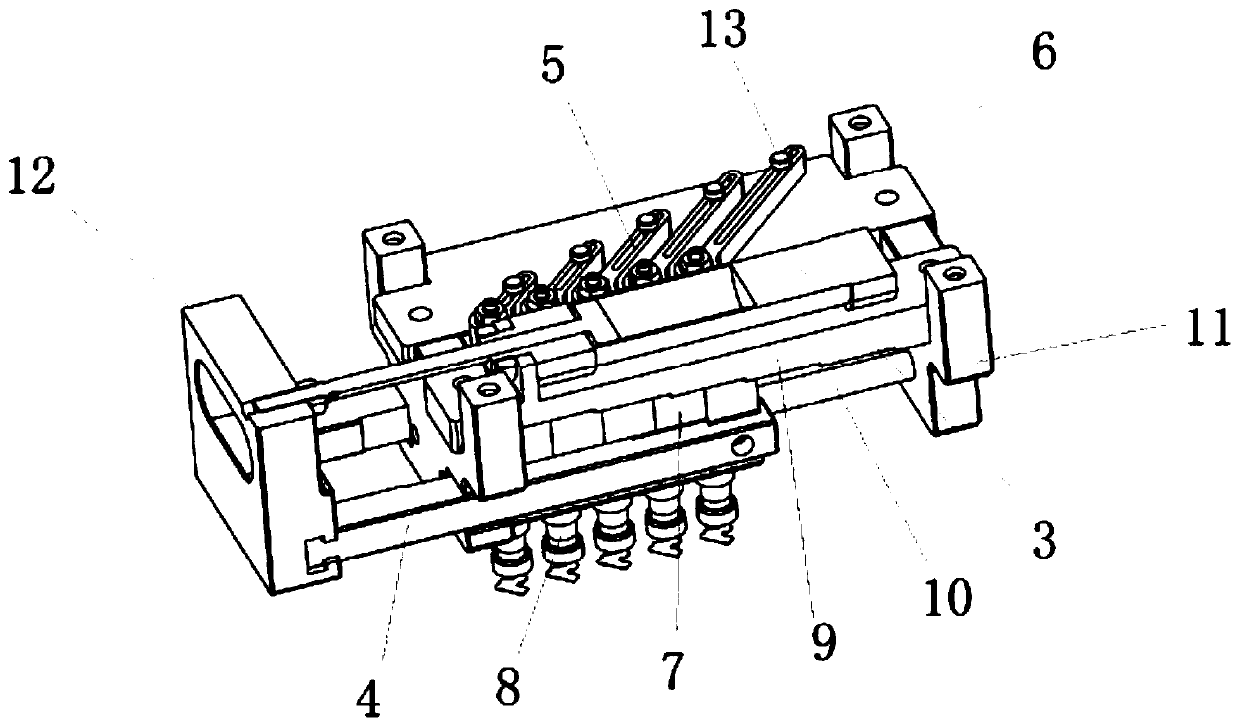

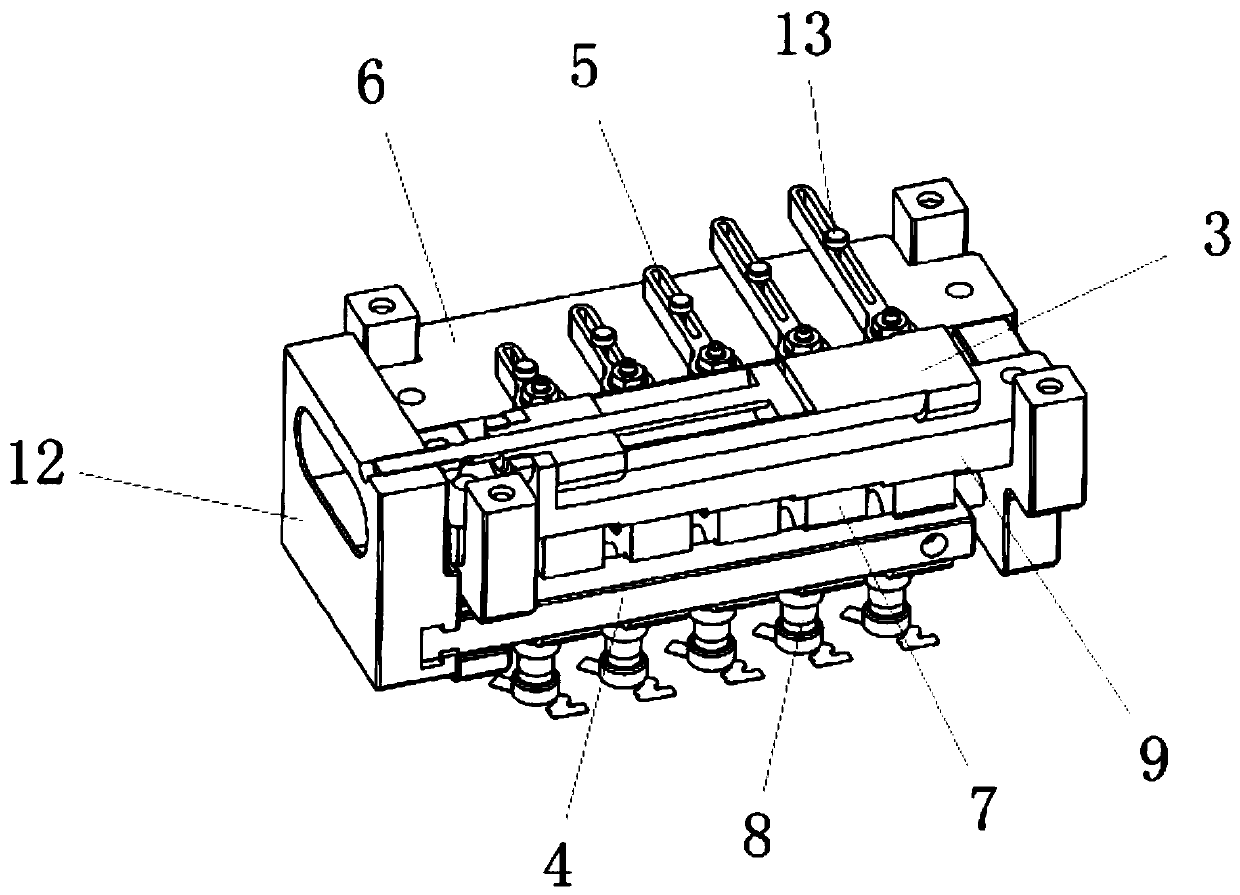

[0038] see Figure 1-8 , the present invention provides the following technical solutions: a multi-pitch angle synchronous adjustment device, including two sealing plates 11, a guide post 10 is connected between the two sealing plates 11, five sliders 7 are slidably connected to the guide post 10, The slider 7 is rotatably connected with a vacuum suction rod 8, and a displacement plate 6 is also connected between the two sealing plates 11. The displacement plate 6 is slidably connected with a rocker arm 5 corresponding to the slider 7. The other end is connected with the top of the vacuum suction rod 8, the two sides of the slider 7 are respectively connected with the push rod 4, the right end of the push rod 4 is connected with the slider 7 on the right side, and the first card is respectively opened on both sides of the slider 7. slot 71, and the depth of the first card slot 71 on the slider 7 increases sequentially from right to left, and the push rod 4 is provided with a f...

Embodiment 2

[0048]The difference between this embodiment and Embodiment 1 is that further, the length of the rocker arm 5 decreases successively from right to left, and the inside of the rocker arm 5 is provided with a chute 51, and the rocker arm 5 is connected to the displacement position through the positioning shaft 13. On the plate 6, and the end of the positioning shaft 13 passes through the chute 51 and is connected to the displacement plate 6.

[0049] Further, the positioning rotating shaft 13 is distributed obliquely on the displacement plate 6 , and the distance from the positioning rotating shaft 13 to the corresponding vacuum suction rod 8 decreases successively from right to left.

[0050] Further, the upper end of the vacuum suction rod 8 is provided with a limiting groove 81 , and the end of the rocker arm 5 is provided with a limiting sleeve 52 , and the limiting sleeve 52 is sleeved on the limiting groove 81 .

[0051] By adopting the above technical solution, the moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com