Wall structure of house building and construction method

A technology for building walls and houses, applied in building components, building structures, buildings, etc., can solve the problems of troublesome installation, low space utilization, and inability to place blocks, so as to achieve convenient installation of blocks and improve space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

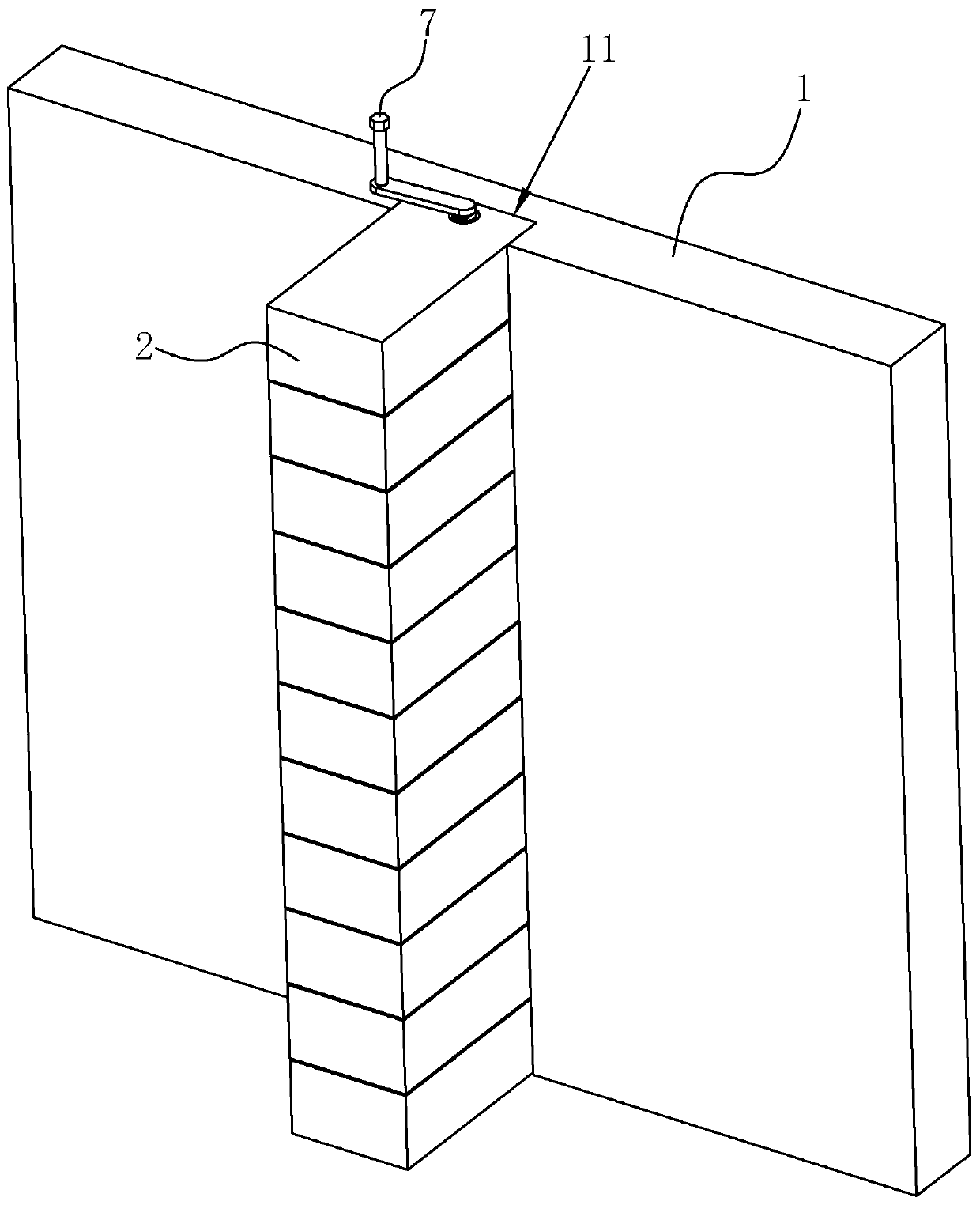

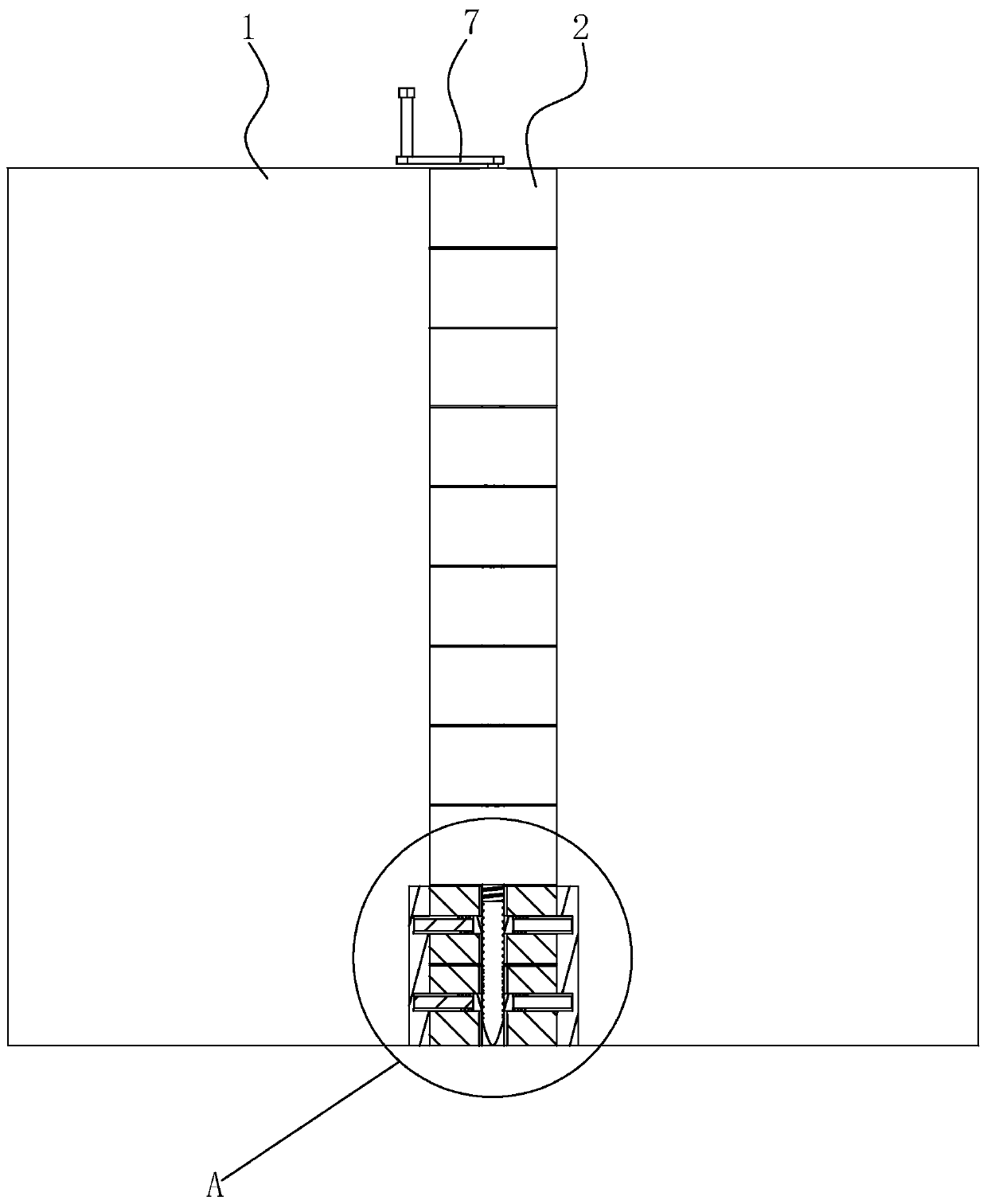

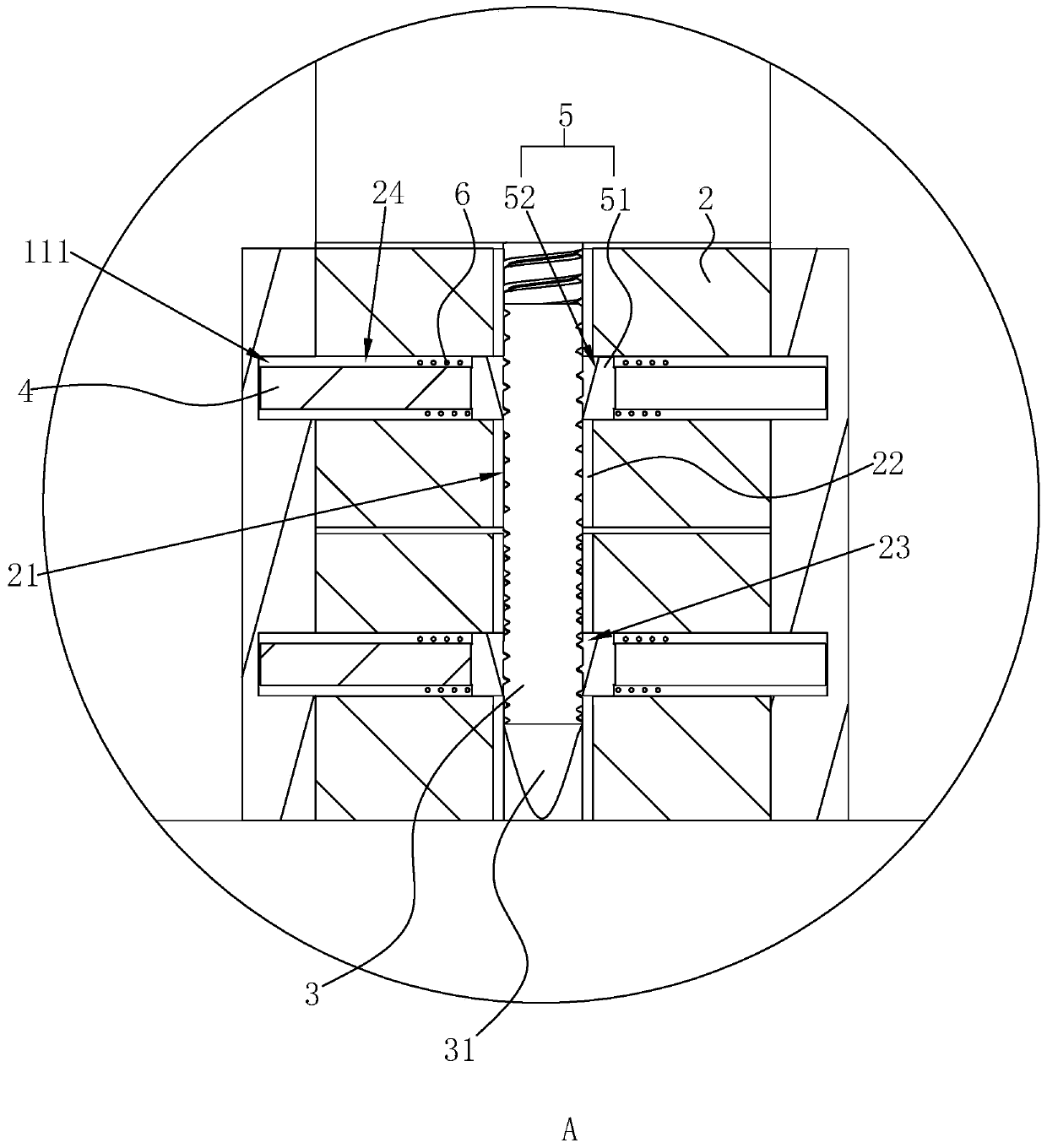

[0042] Example 1: refer to figure 1 , Image 6 , is a building wall structure disclosed in the present invention, comprising a concrete wall 1 and a masonry wall, the masonry wall is formed by stacking a plurality of blocks 2, and the concrete wall 1 is along the concrete wall 1 There is a vertical slot 11 in the height direction of the wall, the vertical slot 11 is used to accommodate the block 2, and the length of the vertical slot 11 is the same as the height of the concrete wall 1; figure 2 , image 3 , the block 2 is provided with a through hole 21, and the length direction of the through hole 21 is parallel to the thickness direction of the block 2. After a plurality of blocks 2 are stacked, the axis of the through hole 21 on each block 2 is in the same vertical direction. On a straight line, that is, the through holes 21 on the plurality of blocks 2 can form a channel.

[0043] like image 3 As shown, a horizontal hole 24 connected to the through hole 21 is lateral...

Embodiment 2

[0051] Embodiment 2: a construction method of a building wall structure, comprising the following steps:

[0052] Step 1. First stack the blocks 2 vertically and put them into the vertical groove 11 in turn, so that the stacked blocks 2 form a masonry wall and fill the vertical groove 11. At this time, the height of the masonry wall is the same as the vertical groove 11. The lengths of the blocks 2 are the same, and the horizontal holes 24 on the block 2 also correspond to the abutting grooves 111 on the inner wall of the vertical groove 11 respectively;

[0053] Step 2: Insert the connecting rod 3 from the through hole 21 on the topmost block 2, then insert the rectangular insertion rod 71 on the crank handle 7 into the rectangular slot 32, and rotate the connecting rod 3 to make the connecting rod 3 gradually. Screw it into the reinforcement cylinder 22 in the through hole 21, let the connecting rod 3 pass through the stacked blocks 2 successively until it touches the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com