An isolation system for cantilevered scaffolding

A technology of cantilevered scaffolding and isolation system, which is applied in the field of scaffolding, can solve the problem of inconvenient adjustment of steel plates, and achieve the effect of preventing falling and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

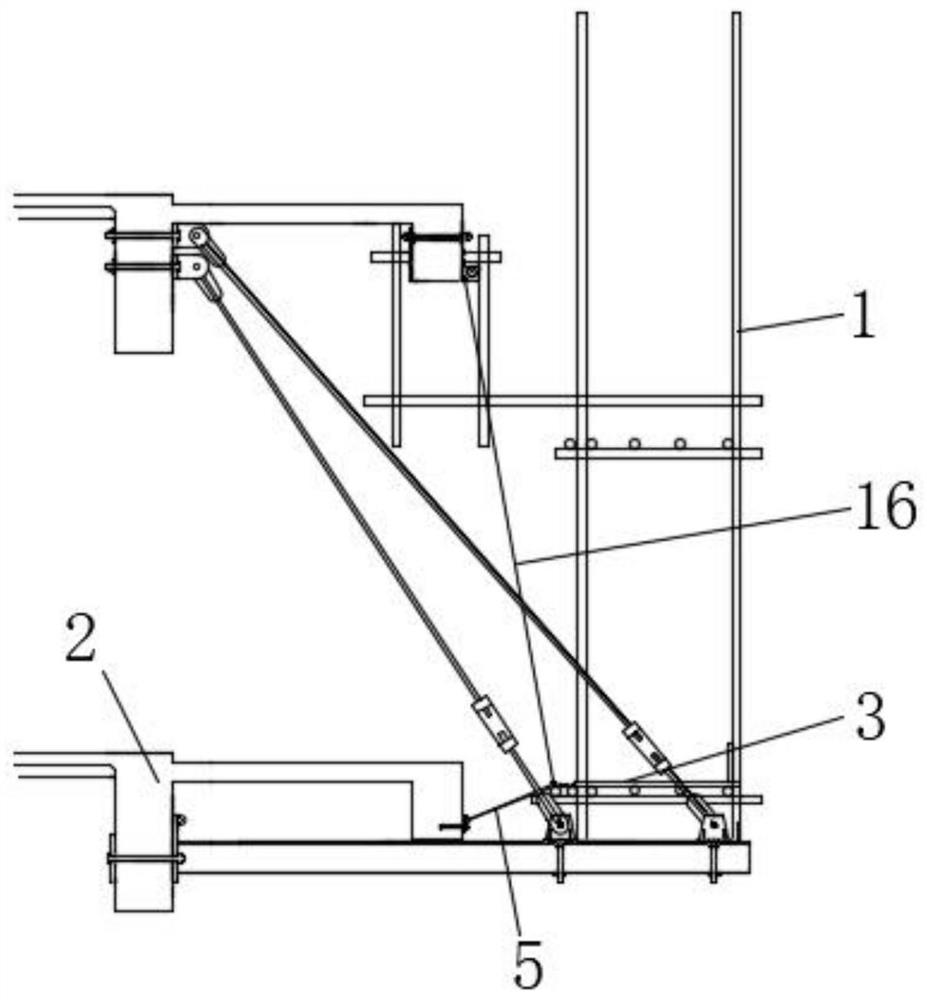

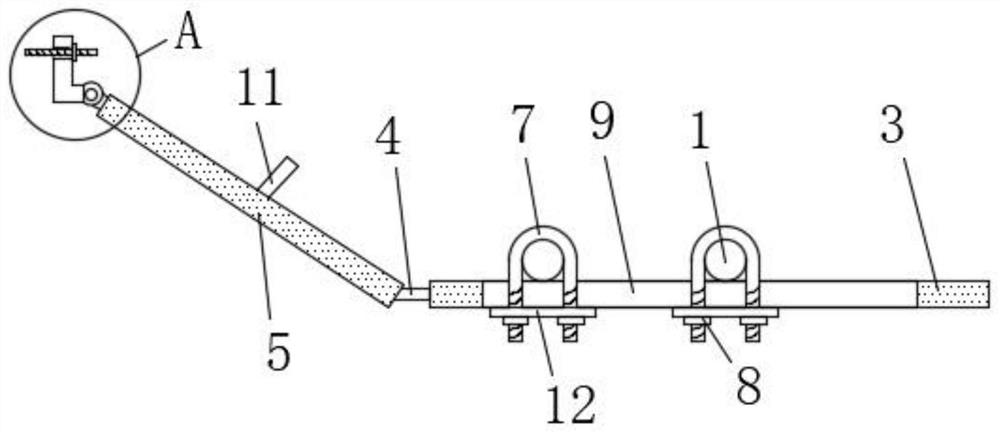

[0018] Embodiment: an isolation system for cantilevered scaffolding, including scaffolding 1 and building structural beams 2, a first steel plate 3 and a second steel plate 5 are arranged between the nodes of the scaffolding 1 and the building structural beams 2, the first steel plate 3 and the building structural beam 2 are provided. The second steel plates 5 are rotatably connected by hinges 4, and a baffle plate 11 is fixedly connected to the top of the second steel plates 5, which can prevent objects from falling. A protective net 16 is provided between the scaffold 1 and the building structural beam 2, and the protective net 16 is a soft isolation, which is beneficial to reduce the impact force of falling objects;

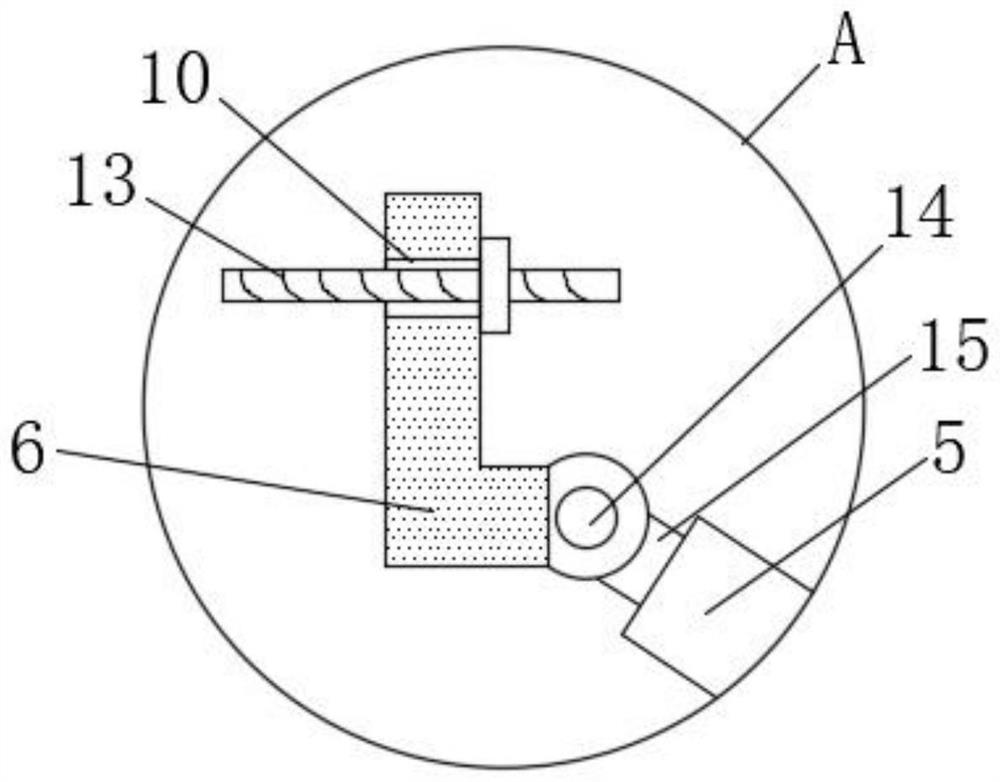

[0019] A bar-shaped hole 9 is opened on the top of the first steel plate 3, and a U-shaped screw 7 is movably connected to the inside of the bar-shaped hole 9. A nut 8 is threadedly connected to each end, and a washer 12 is also sleeved to fix the first steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com