Device and method for rapidly measuring moisture content of slurry

A technology of moisture content and slurry, which is applied in the direction of measuring devices, specific gravity measurement, and analysis of materials, can solve the problems of less test volume, time-consuming and laborious, and inability to realize rapid on-site measurement and fixed-point continuous monitoring, etc., and achieves low manufacturing costs. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0021] Embodiment of the device for quickly measuring the moisture content of large batches of slurry of the present invention

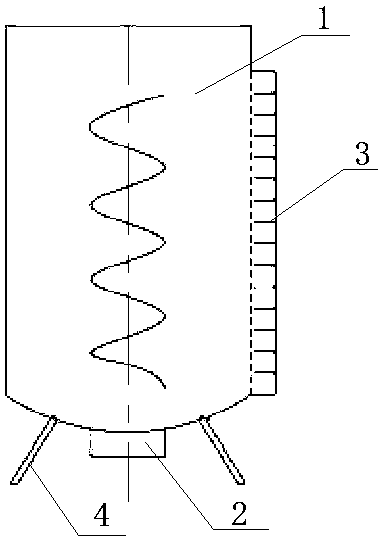

[0022] Refer to attached figure 1 , the present embodiment comprises a slurry container body 1, the center of the bottom of the slurry container body 1 is provided with a weight sensor 2, and the outside of the slurry container body 1 is provided with a movable slurry height gauge 3, and the slurry height gauge 3 It communicates with the slurry container body 1. The slurry container body 1 is a barrel-shaped container, and the bottom thereof is provided with supporting legs 4 for maintaining balance.

[0023] In this embodiment, the slurry container body 1 is a barrel-shaped container with a radius r of 1.15 meters and a height h of 2.98 meters. The height of slurry height gauge 3 adapts to the height of slurry co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com