Dimming glass and preparation method thereof

A dimming glass and dimming technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of light leakage in the area where the PS is located

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

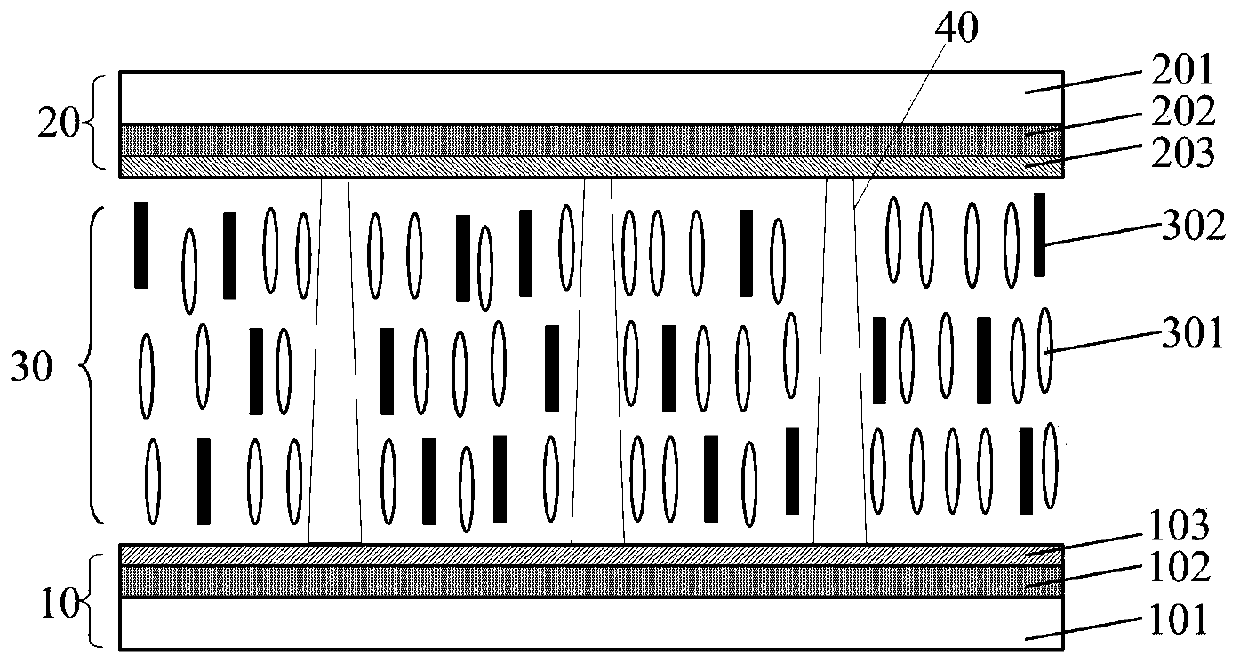

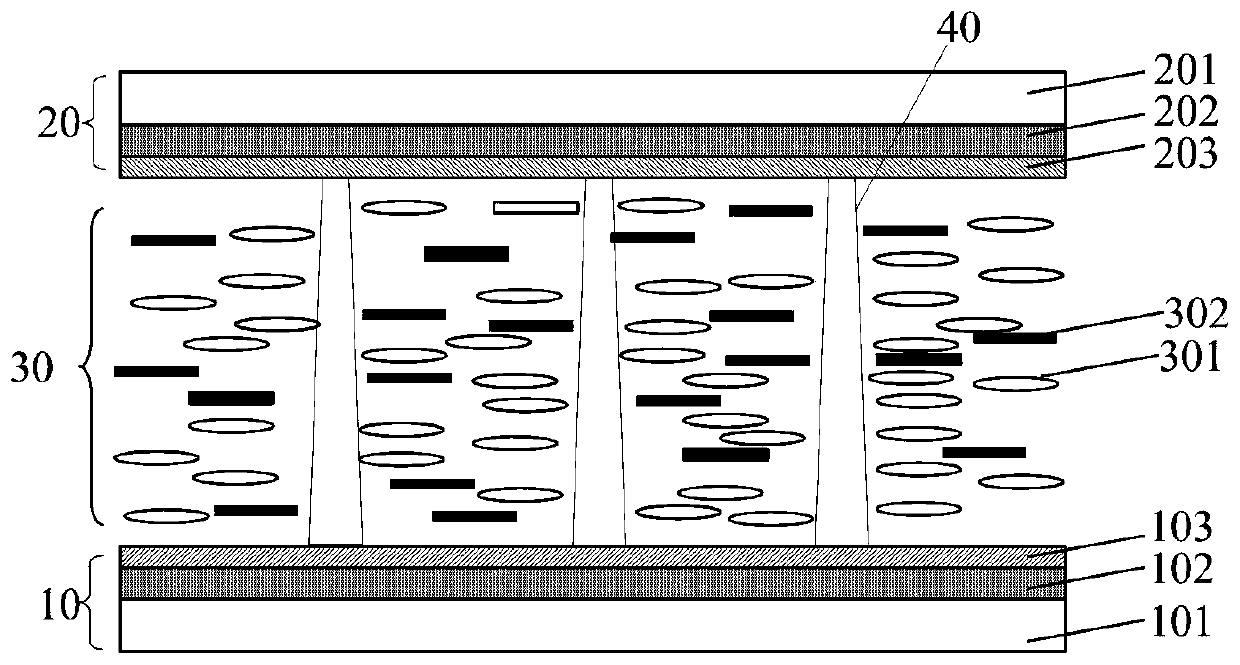

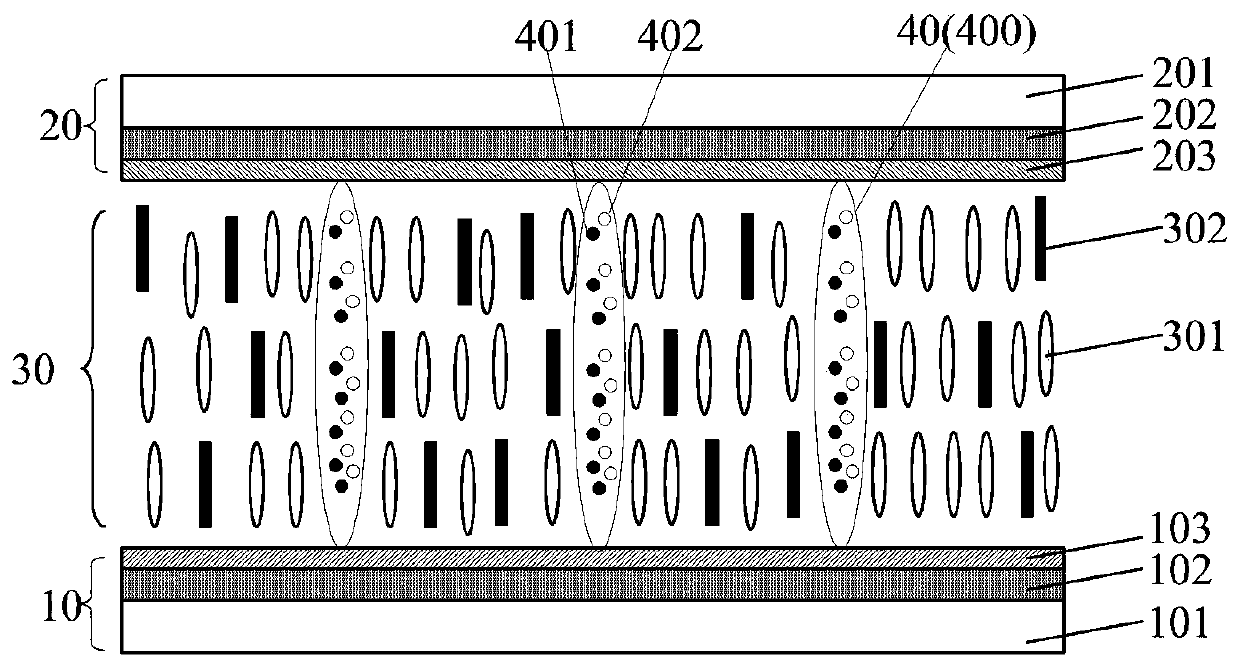

[0038] image 3 and Figure 4 A structural schematic diagram of a dimming glass provided for an embodiment of the present invention, as shown in image 3 and Figure 4 As shown, the dimming glass includes: at least one layer of dimming structure; the dimming structure includes: a first substrate 10 and a second substrate 20 oppositely arranged, and a liquid crystal layer 30 between the first substrate 10 and the second substrate 20 , and maintain the thick spacer 40 of the liquid crystal layer 30 between the first substrate 10 and the second substrate 20; the liquid crystal layer 30 includes: liquid crystal molecules 301; the spacer 40 includes: microcapsules 400; encapsulated in the microcapsules 400 Black charged particles 401 and transparent charged particles 402; wherein, the black charged particles 401 and the transparent charged particles 402 have opposite polarities.

[0039] Such as image 3 As shown, when no voltage is applied between the first substrate 10 and th...

Embodiment 2

[0057] Based on the same inventive concept, an embodiment of the present invention provides a method for preparing a dimming glass, Figure 6 A schematic flow chart of a method for preparing a dimming glass provided in an embodiment of the present invention, as shown in Figure 6 As shown, the preparation method of the dimming glass comprises the following steps:

[0058] S601, encapsulating uniformly mixed black charged particles and transparent charged particles in microcapsules.

[0059] S602. Print the microcapsules on the first substrate through a screen printing process, so that the microcapsules form a preset pattern on the first substrate.

[0060] S603, coating a frame sealant on the first substrate formed with the microcapsules.

[0061] S604, drop the liquid crystal molecules into the region defined by the sealant on the first substrate.

[0062] S605, aligning the second substrate and the first substrate to form a dimming structure.

[0063] The method for prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com