A horn shell and its installation process

A shell and horn technology, applied in the direction of sensors, electrical components, etc., can solve the problems of time-consuming, cumbersome process, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

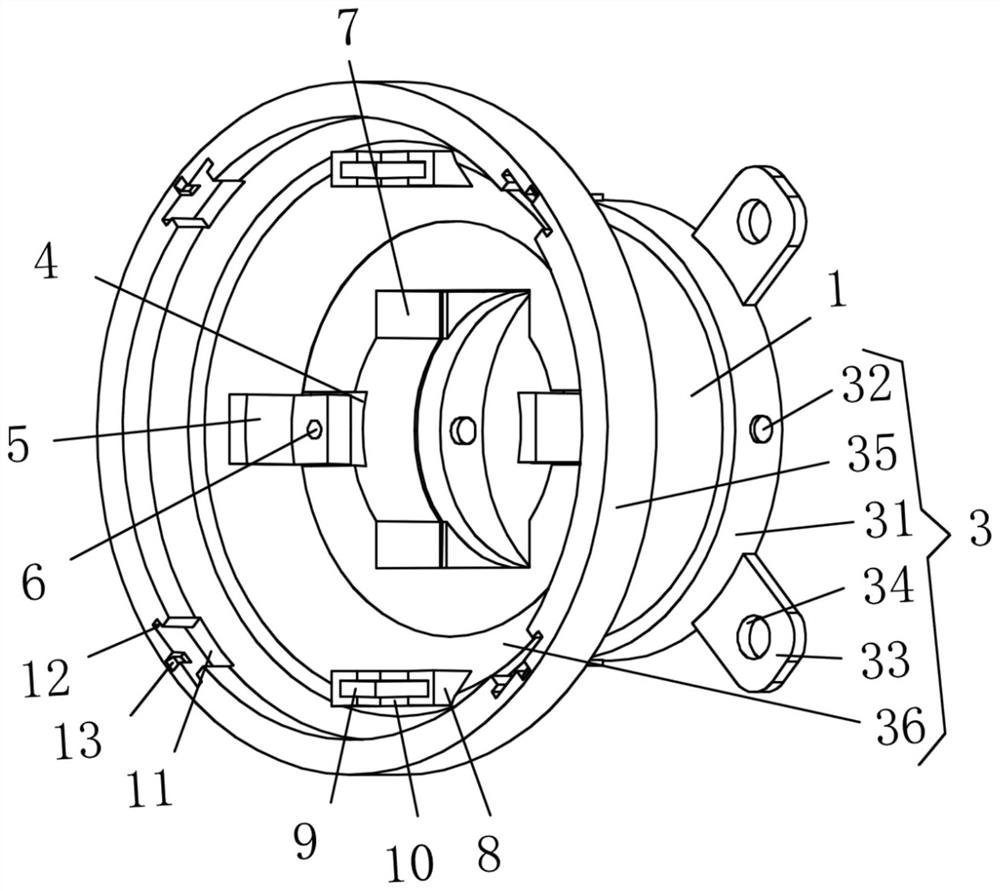

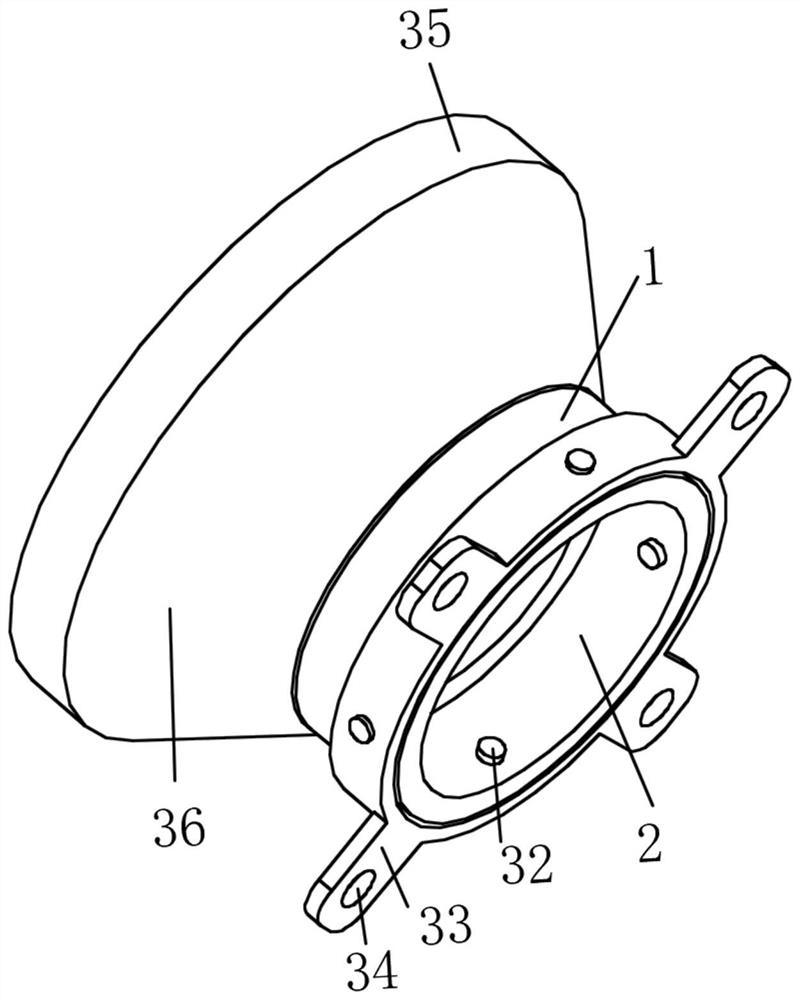

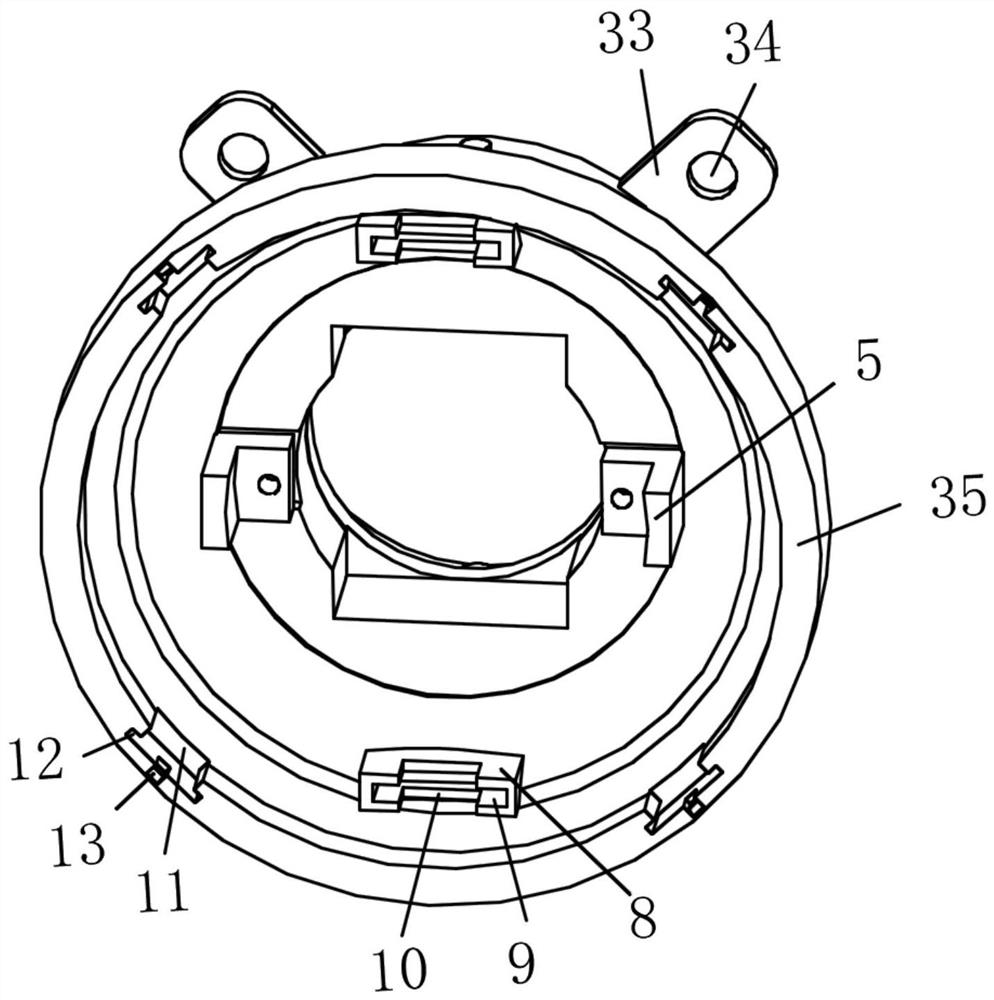

[0025] Embodiment 1: A speaker shell, including a mounting seat 1, a mounting groove 2 and a mounting assembly 3, the mounting seat 1 is arranged in a cylindrical shape, and the middle position of the mounting seat 1 is provided with a mounting groove 2, and the mounting seat 1 is close to The side of the lower end position is provided with installation holes in a circular array. The installation assembly 3 includes a fixed ring 31, a positioning pin 32, a fixed rod 33, a fixed hole 34, an installation side rail 35 and an oblique connection cover 36. On the fixed ring 31 A through hole corresponding to the mounting hole at the lower end of the mounting base 1 is provided, and the fixing ring 31 is fixedly connected with the mounting base 1 through a positioning pin 32, and the outer surface of the lower end of the fixing ring 31 is fixedly connected with four fixing rings in an annular array. Rod 33, the end of fixed rod 33 runs through and is provided with fixing hole 34, and ...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is:

[0034] In this embodiment, it also includes a fixed block 5 and a connecting hole 6, the fixed block 5 is L-shaped, and the middle position of the lower end of the fixed block 5L is provided with a connecting hole 6, and the connecting hole 6 and the screw thread on the fixing groove 4 The holes are threaded together by hexagon socket screws. The size of the connecting hole 6 on the fixing block 5 is always the same as the diameter of the screw hole on the fixing groove 4. The size of the fixing block 5 can be selected according to the model of the speaker, and it has better adaptability during use, which greatly improves the speaker shell. available range.

[0035] Also includes a square card slot 7, the side length of the square card slot 7 is the same as the diameter of the installation slot 2, and the square card slot 7 is opened on the surface of the middle position of the upper end of the installation ...

Embodiment 3

[0037] The difference between this embodiment and Embodiment 1 is:

[0038] In this embodiment, it also includes a vertical clamping block 8, a positioning groove 9 and a middle clamping groove 10. The vertical clamping block 8 is arranged in a square shape, and there are two vertical clamping blocks 8, two vertical clamping blocks 8 are respectively fixedly connected on the inner surface on both sides of the upper end of the oblique connection cover 2, the middle position of the vertical block 8 is provided with a horizontal positioning groove 9, and the middle position of the vertical block 8 is provided with a longitudinal middle slot 10. The positioning groove 9 and the middle engaging groove 10 provided on the vertical clamping block 8 can realize two-way position fixing of the horn vibration cavity.

[0039]It also includes an end positioning groove 11, a glue groove 12 and a glue injection port 13. There are four end positioning grooves 11 in total. Glue grooves 12 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com