Method for producing components from prefabricated parts designed as hollow bodies

A technology for producing parts and prefabricated parts, which is applied in the field of producing parts from prefabricated parts designed as hollow bodies, and can solve problems such as the production of parts that are not suitable for prefabricated parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

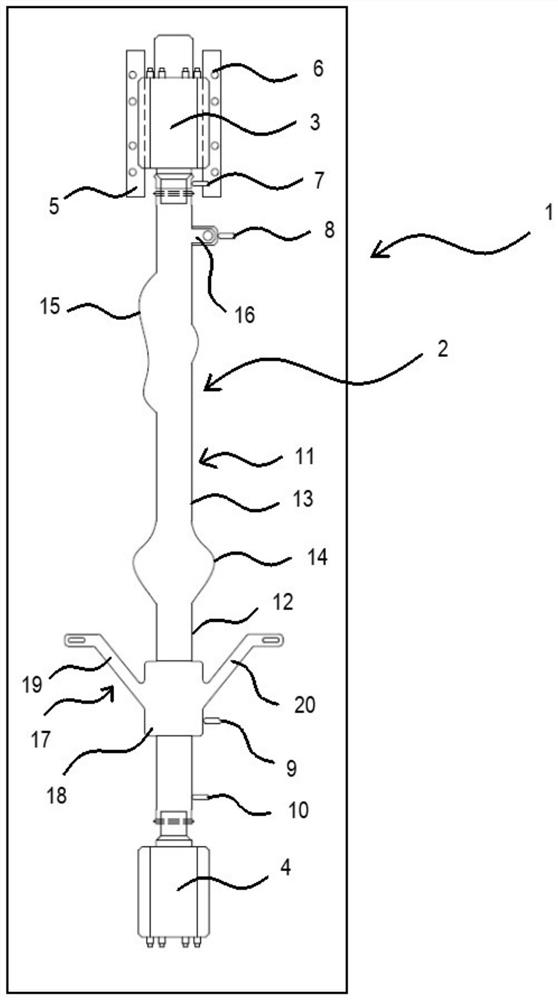

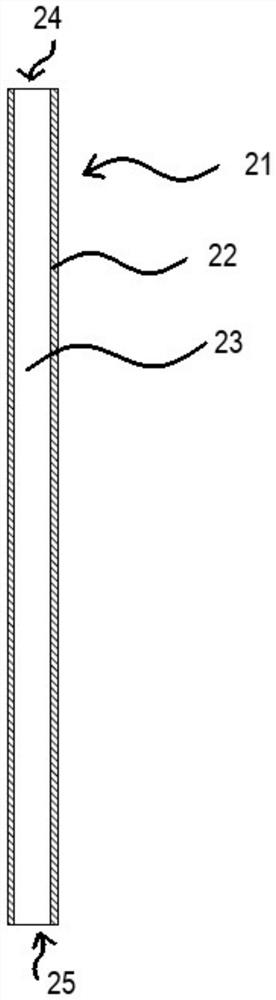

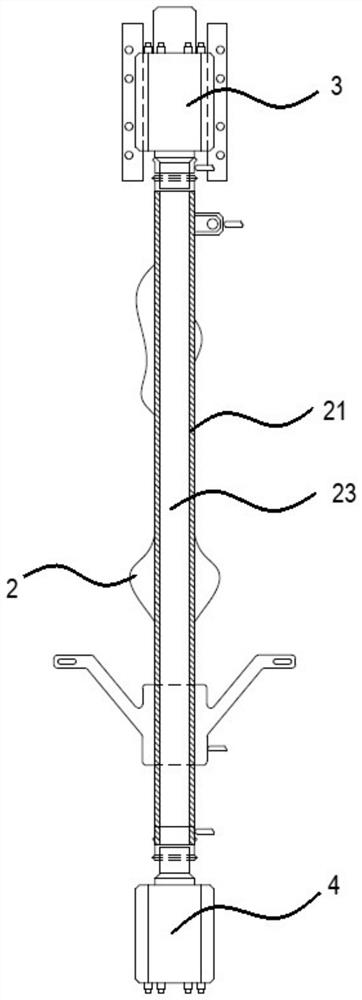

[0051] figure 1 A mold 1 with a mold cavity 2 with a first injection head 3 and a second injection head 4 is shown. The mold is part of an injection molding machine not otherwise shown in the figures. Each injection head 3 , 4 is equipped with a drive, not shown in the figures, which actively moves the two injection heads 3 , 4 into and out of the mold cavity 2 . The mold cavity 2 is elongated. When moving in the longitudinal direction of the mold cavity, the two injection heads 3 , 4 move relative to each other when entering the mold cavity 2 and move away from each other when moving out of the mold cavity 2 . according to figure 1 The two injection heads 3, 4 are moved out of the mold cavity 2 by means of a drive. The first injection head 3 is also movably mounted on guide rails 5 , 6 . The melts of two different plastics are injected into the mold cavity 2 through a total of four needle valves 7 , 8 , 9 , 10 . In addition, fluid is injected into the liquid melt throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com