Double-sided adhesive tape punching process

A double-sided tape and process technology, applied in metal processing and other directions, can solve the problems of unstable product dimensional tolerances, changes in outer frame dimensions, and high difficulty in mold adjustment, saving mold adjustment time, reducing mold adjustment difficulty, and reducing cumulative tolerances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0022] Specific embodiment 1: Please refer to Figure 1 to Figure 7 In an embodiment of the present invention, a double-sided tape punching process includes die-cutting using a knife die and includes the following steps:

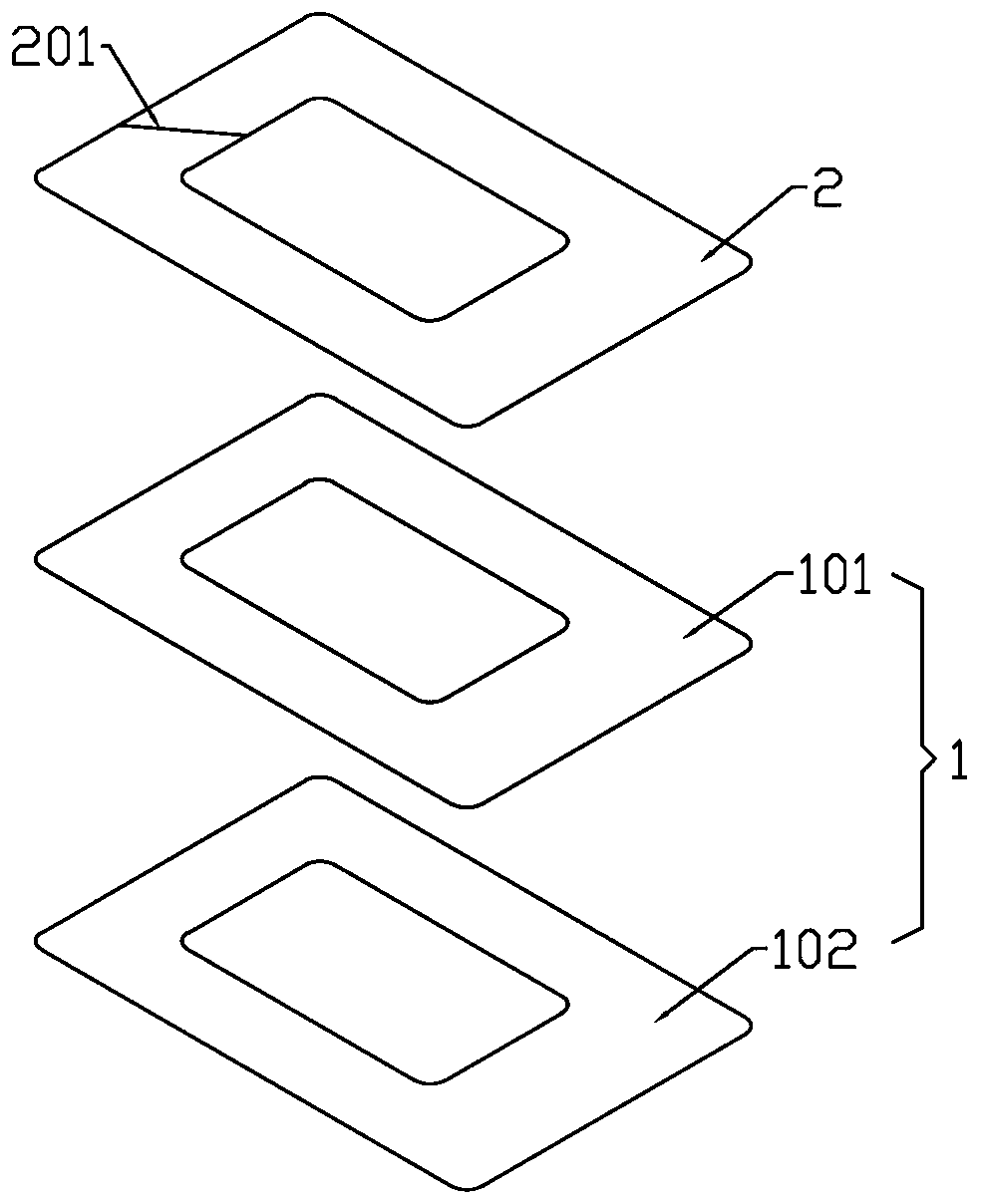

[0023] (A) In the laminating machine, the adhesive surface 101 of the double-sided tape 1 and the blue film 2 are attached to form a roll. The double-sided tape includes the adhesive surface 101 and the release bottom paper 102, and the blue film 2 is attached At the top of the rubber surface 101, the release paper 102 is at the bottom of the rubber surface 101;

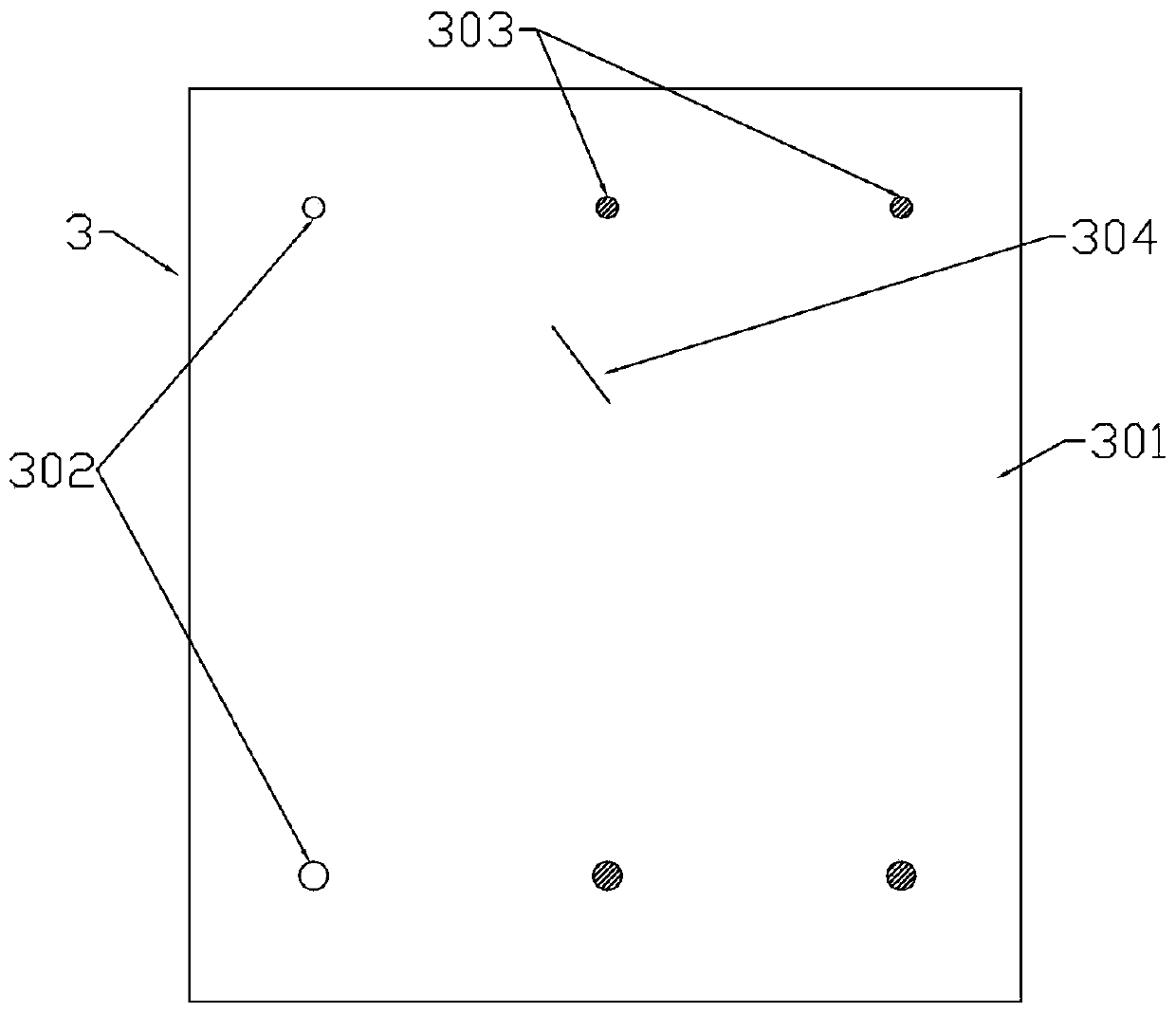

[0024] (B) The roll of material in step A is punched with the first die 3, the first positioning holes 6 are punched on the left and right sides of the roll, and the knife edge 201 is punched between the two first positioning holes 6. The blue film 2 at the broken edge 201 is cut and the glue is continuous, and a semi-finished product 1 is obtained;

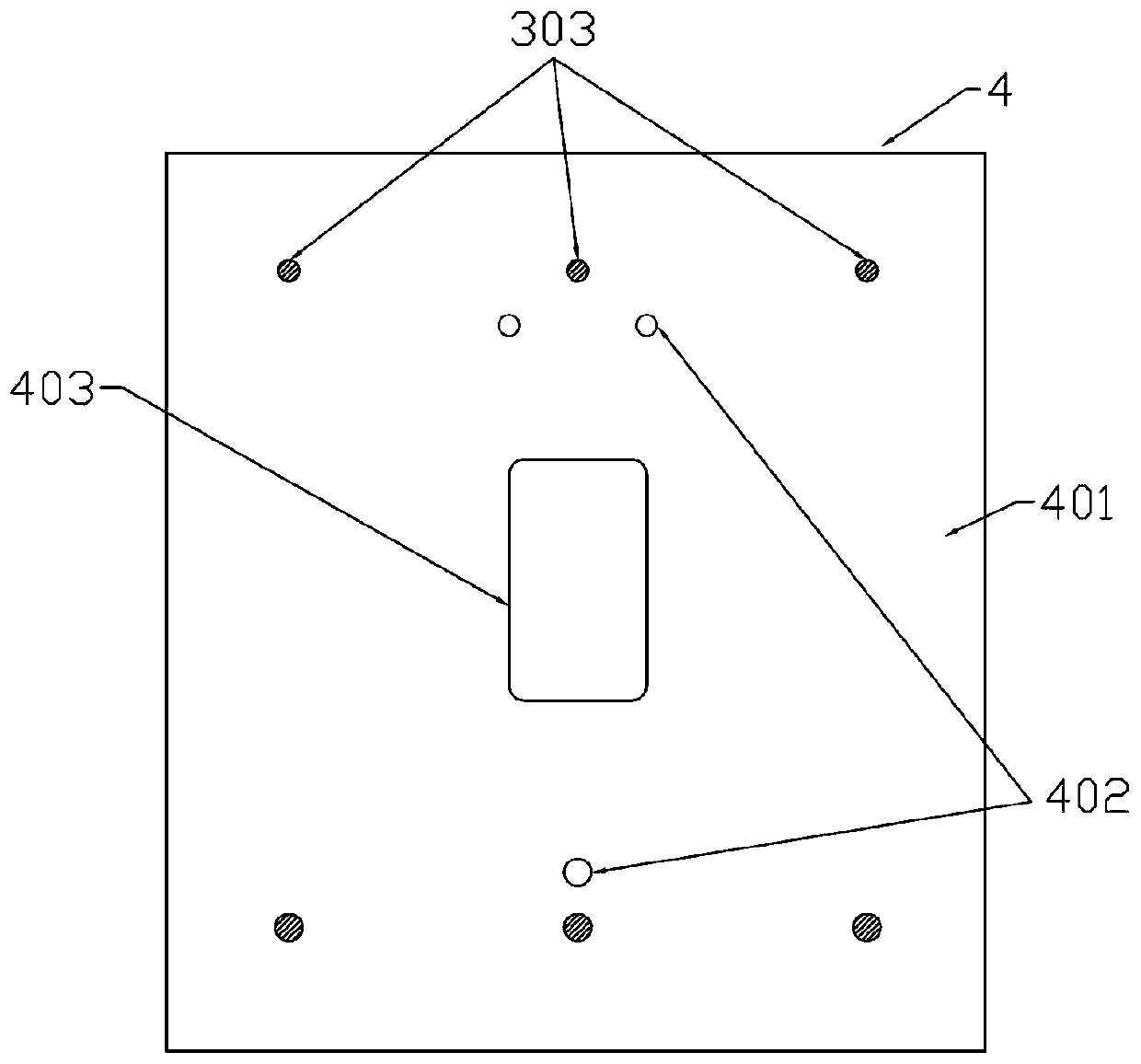

[0025] (C) The semi-finished product in step C is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com