A kind of active embossing equipment for low melting point film

A technology with low melting point and active force, which is applied in the field of film embossing equipment, can solve the problems of shallow embossing depth of embossing needles, easy rebound of anti-slip points, and increased scrap rate, so as to reduce production costs and use costs, and solve powder Extracorporeal leakage, the effect of improving the imprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

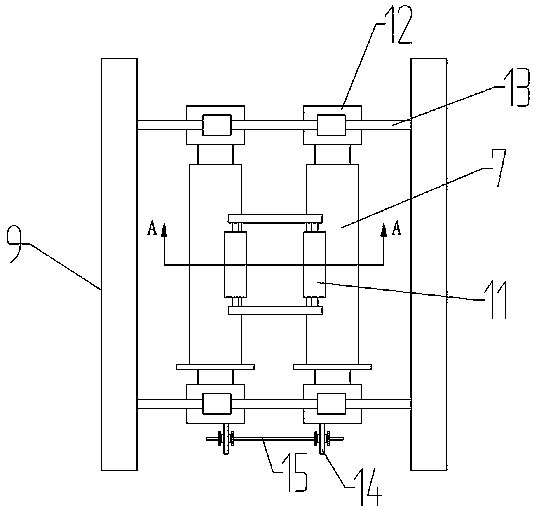

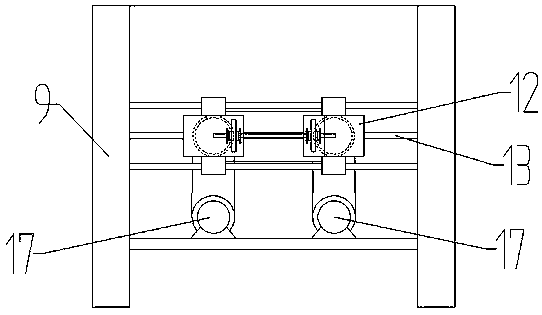

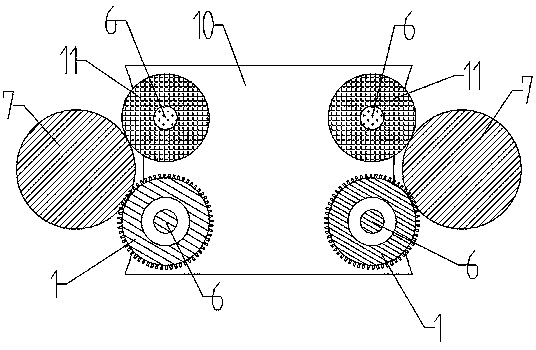

[0035] Example: see Figure 1-8 , a kind of active power embossing equipment for low-melting point film, comprising a frame 9, two rubber rollers 7 are arranged in parallel and at intervals in the frame 9, and the two ends of the rubber roller 7 are respectively connected to the frame through a sliding assembly 9, an embossing assembly for embossing the film is sandwiched between the two rubber rollers 7, and a driving assembly for driving the rubber roller 7 to rotate is fixedly arranged on the frame 9.

[0036] The sliding assembly respectively drives the two rubber rollers 7 to move in opposite or opposite directions, and is used to adjust the distance between the two rubber rollers 7, thereby realizing the adjustment of the extrusion force between the rubber roller 7 and the embossing assembly, and then used for Adjust the embossing pressure and the embossing depth of the embossing unit.

[0037] The sliding assembly includes two sets of guide rods arranged in the frame 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com