Patents

Literature

34results about How to "Adjust extrusion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

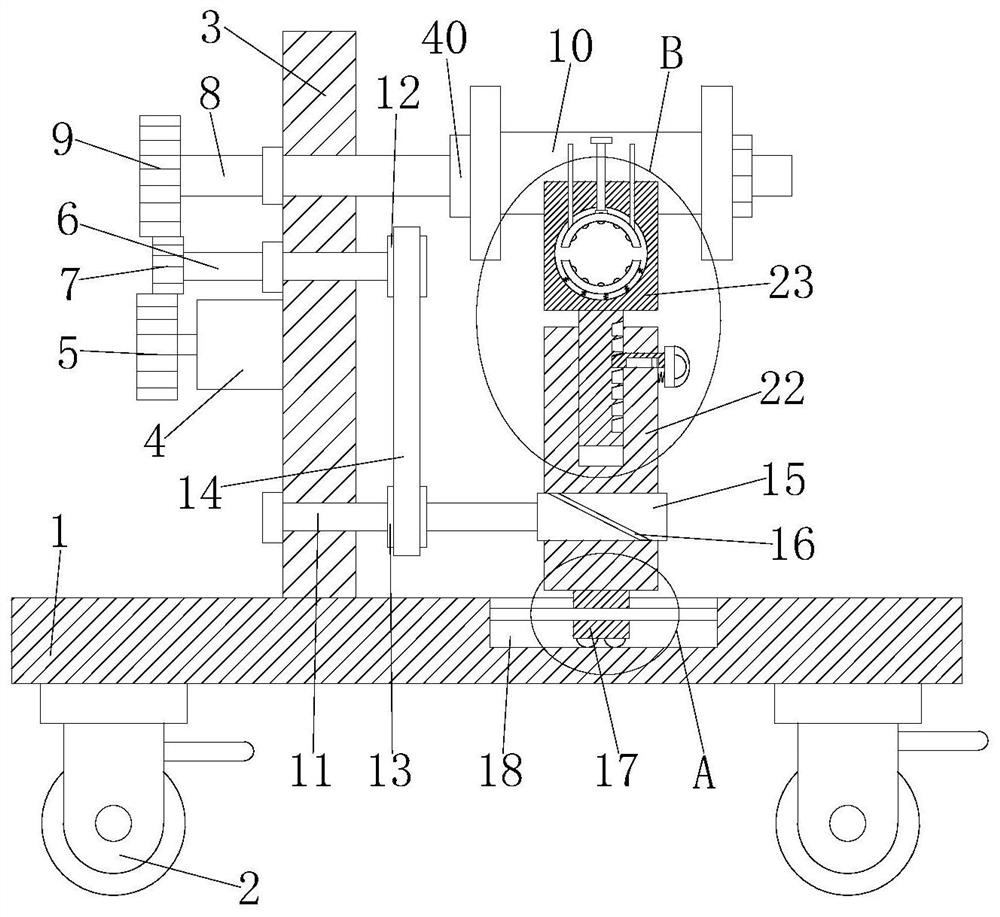

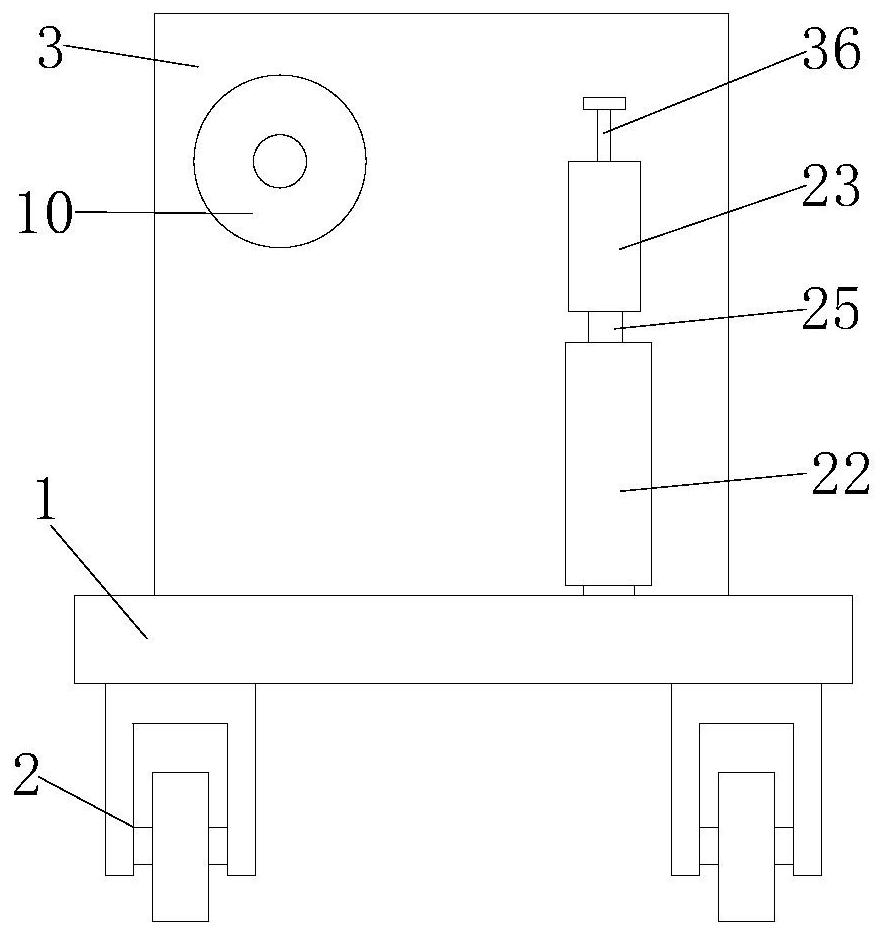

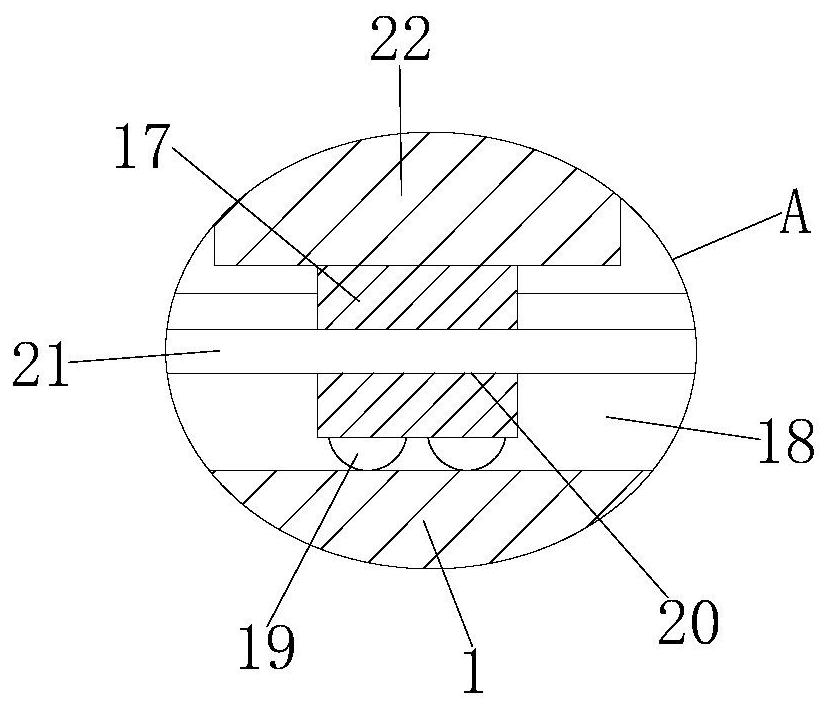

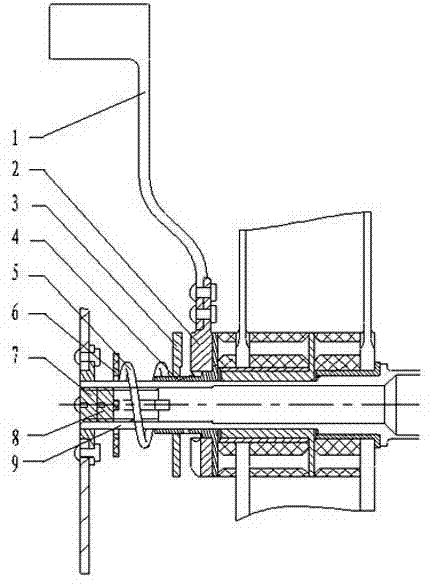

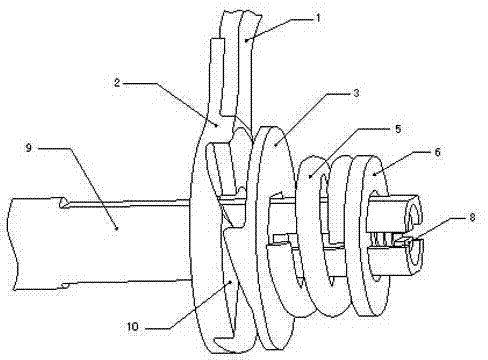

Tension adjustment device for copper wire unwinding rack

The invention belongs to the technical field of copper wire unwinding, and particularly relates to a tension adjustment device for a copper wire unwinding rack. The problems that winding and unwindingof a copper wire are nonuniform due to the fact an existing steel wire unwinding rack cannot perform even unwinding or winding when the copper wire is unwound or wound, and the unwinding speed is difficult to control due to the fact that the unwinding tension cannot be adjusted are solved. According to the technical scheme, the tension adjustment device for the copper wire unwinding rack comprises a bottom plate. The bottom of the bottom plate is fixedly connected with four universal wheels, the top of the bottom plate is fixedly connected with a vertical plate, one side of the vertical plateis fixedly connected with a driving structure, a transmission shaft and a winding shaft are transversely installed on the vertical plate in a rotating mode, the transmission shaft is matched with thedriving structure, the winding shaft is matched with the transmission shaft, a winding roller fixedly sleeves the outer side of the winding shaft, a barrier sleeve fixedly sleeves the outer side of the winding shaft, and the winding roller is in contact with the barrier sleeve. The tension adjustment device for the copper wire unwinding rack can perform even unwinding or winding during unwindingor winding of the copper wire, so that the copper wire is uniformly during unwinding and winding, the unwinding tension can be adjusted, and the unwinding speed can be controlled.

Owner:谢洁萍

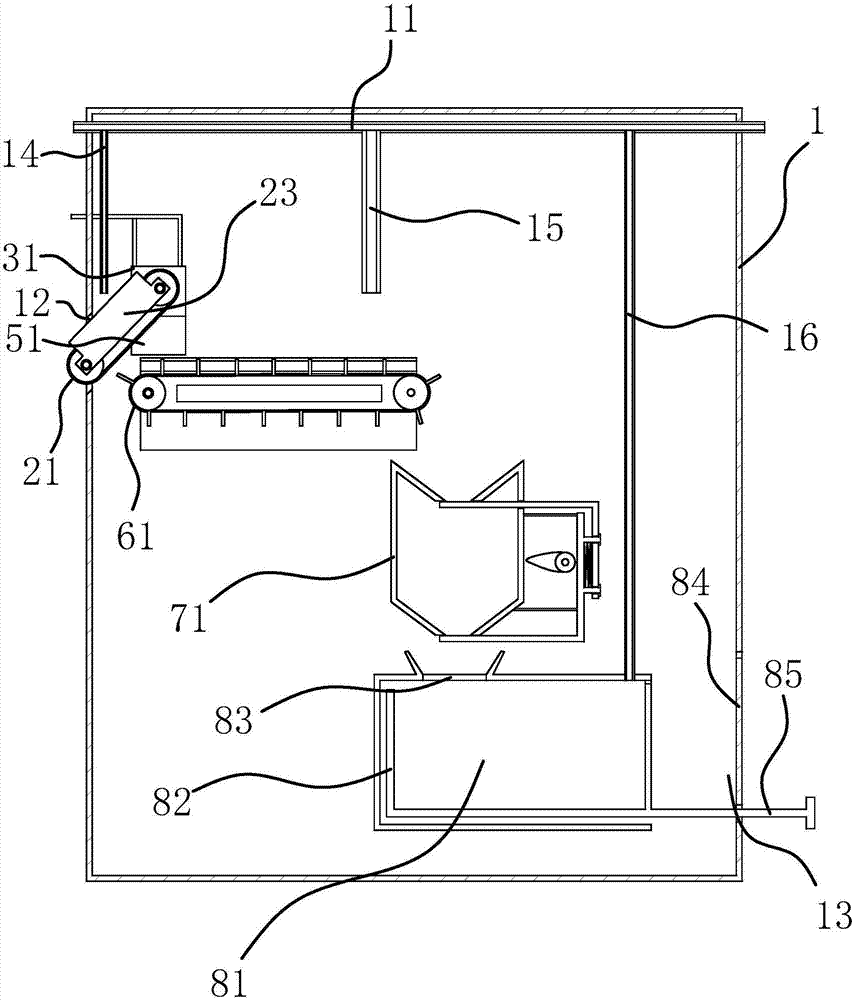

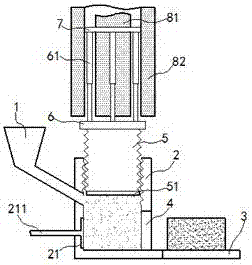

Microwave carbonization equipment

InactiveCN107051389APollution-free operationEasy to sendOther chemical processesMicrowaveMolding machine

The invention provides microwave carbonization equipment, and belongs to the technical field of carbon-making equipment. The microwave carbonization equipment solves the technical problems of serious pollution caused by existing carbon-making equipment and the like. The microwave carbonization equipment comprises a sealed box and a main gas pipe for inflating carbon dioxide gas into the box, a feeding opening and a discharging opening are formed in the box, the feeding opening is provided with a feeding device located in the box, the box is internally and sequentially provided with a wood grinder, a sawdust mixer, a molding machine, a microwave carbonization device, a charcoal activation device and a discharging device, and the discharging device is arranged on the discharging opening; the feeding opening is provided with a first branch gas pipe located in the box, the box is further internally provided with a second branch gas pipe and a third branch gas pipe, the first branch gas pipe, the second branch gas pipe and the third branch gas pipe are all communicated with the main gas pipe, the gas outlet end of the second branch gas pipe is located in the middle of the box, and the third branch gas pipe is connected with the microwave carbonization device. The microwave carbonization equipment has the advantages of having no pollution and the like.

Owner:HUBEI UNIV OF SCI & TECH

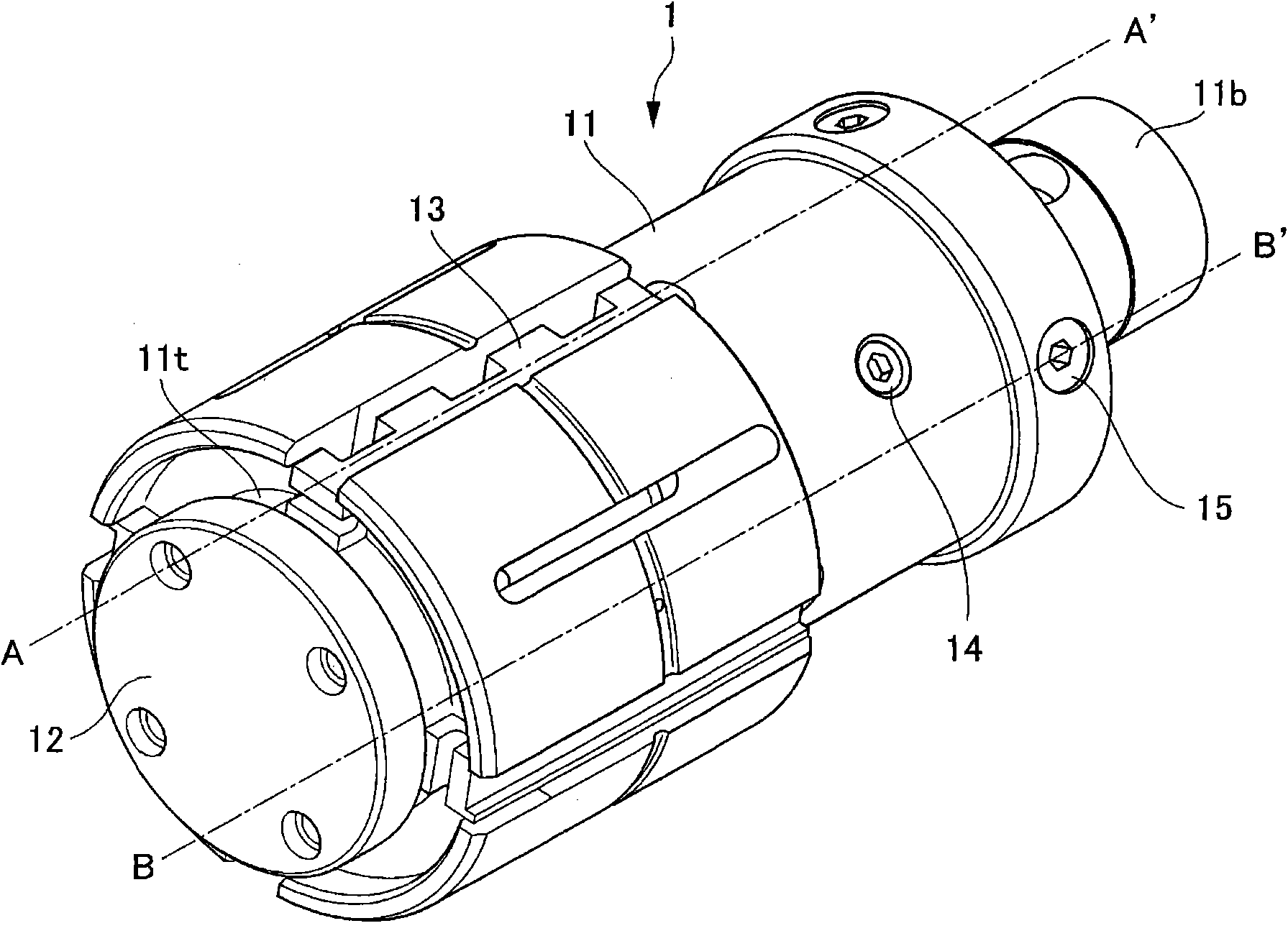

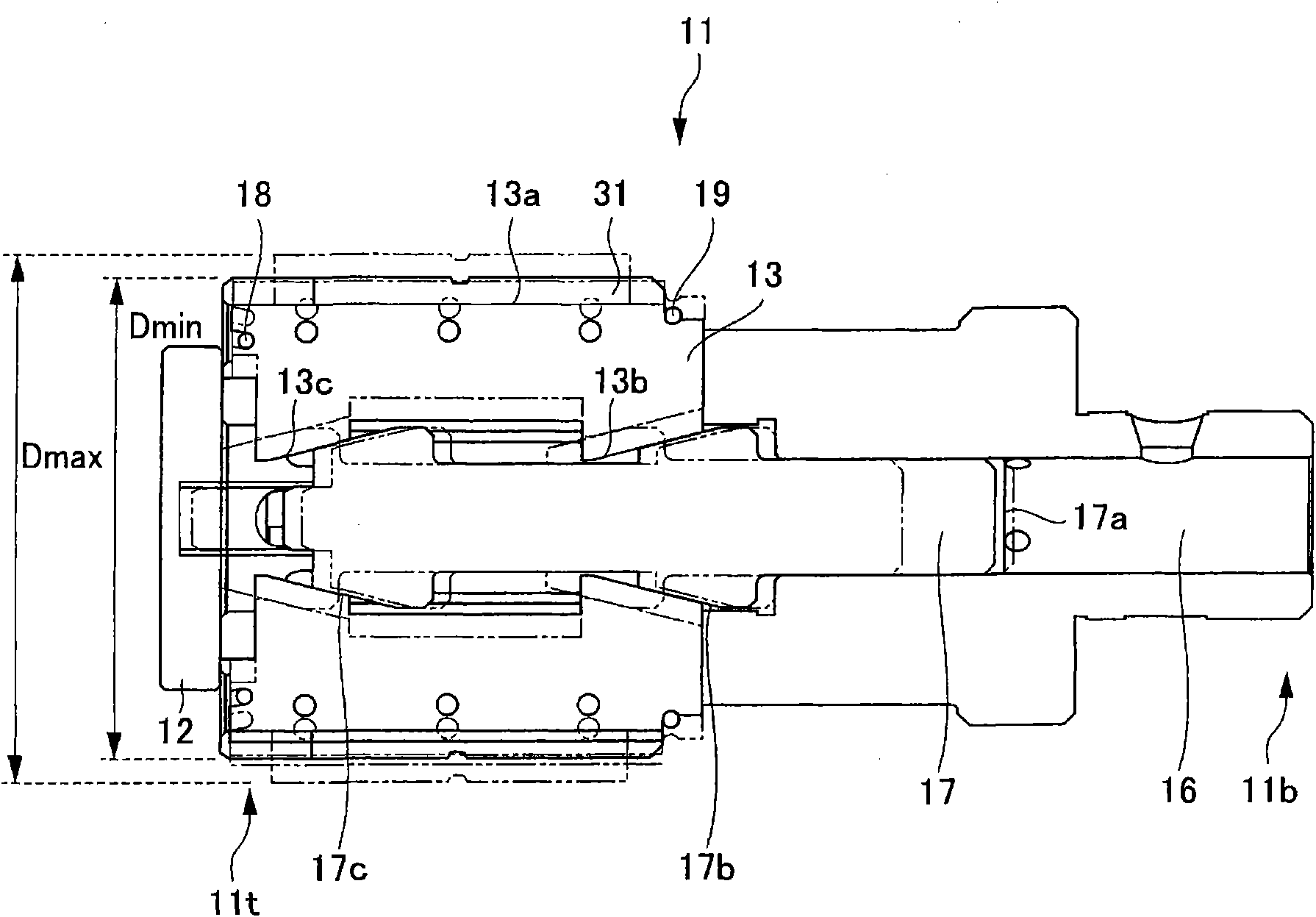

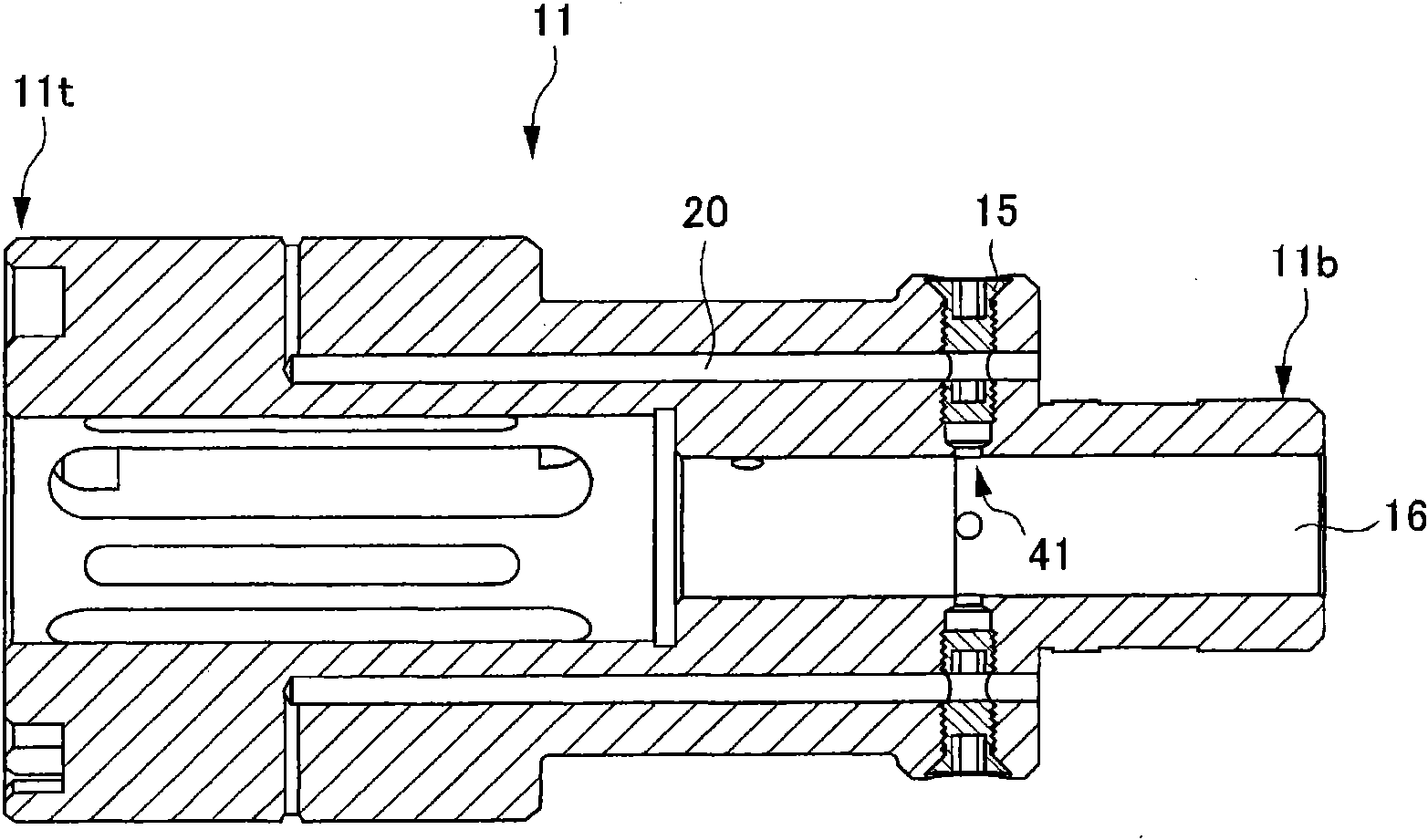

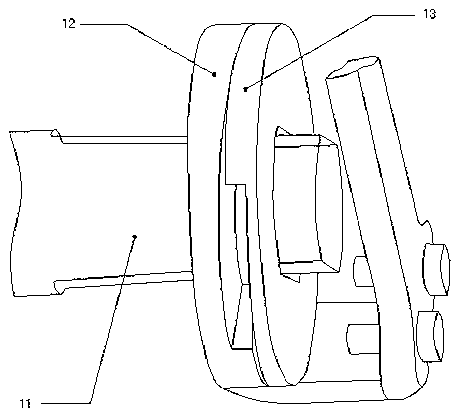

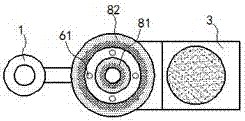

Tool holder

InactiveCN101954619AAdjust extrusion forceReduce operating loadHoning toolsHoning machinesCoolant flowTool holder

A tool holder is provided with a main body, a taper cone, a working portion, a coolant flow passage, and an adjuster. The taper cone includes a taper portion and movable in an axial direction of the main body. The working portion is mounted on an outer peripheral portion of the main body and includes a taper bottom surface which engages with the taper portion. The taper bottom surface is movable in a radial direction of the main body based on a movement of the taper cone in the axial direction. A coolant flows through the coolant flow passage such that a part of the coolant presses and moves the taper cone in the axial direction and another part of the coolant flows out to an outside so as to adjust a pressing force. The adjuster is fitted into a hole penetrating the main body and includes a coolant flow-out hole for adjusting a flow-out of the coolant.

Owner:HONDA MOTOR CO LTD

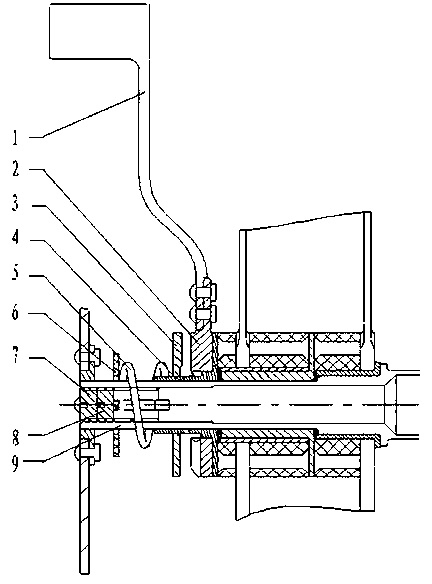

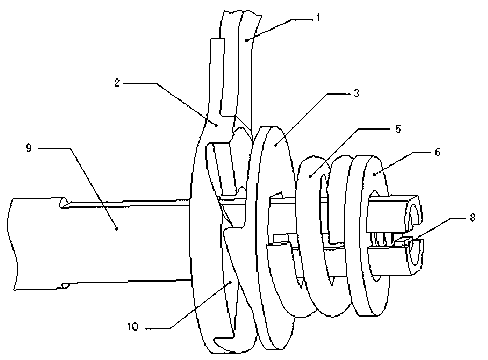

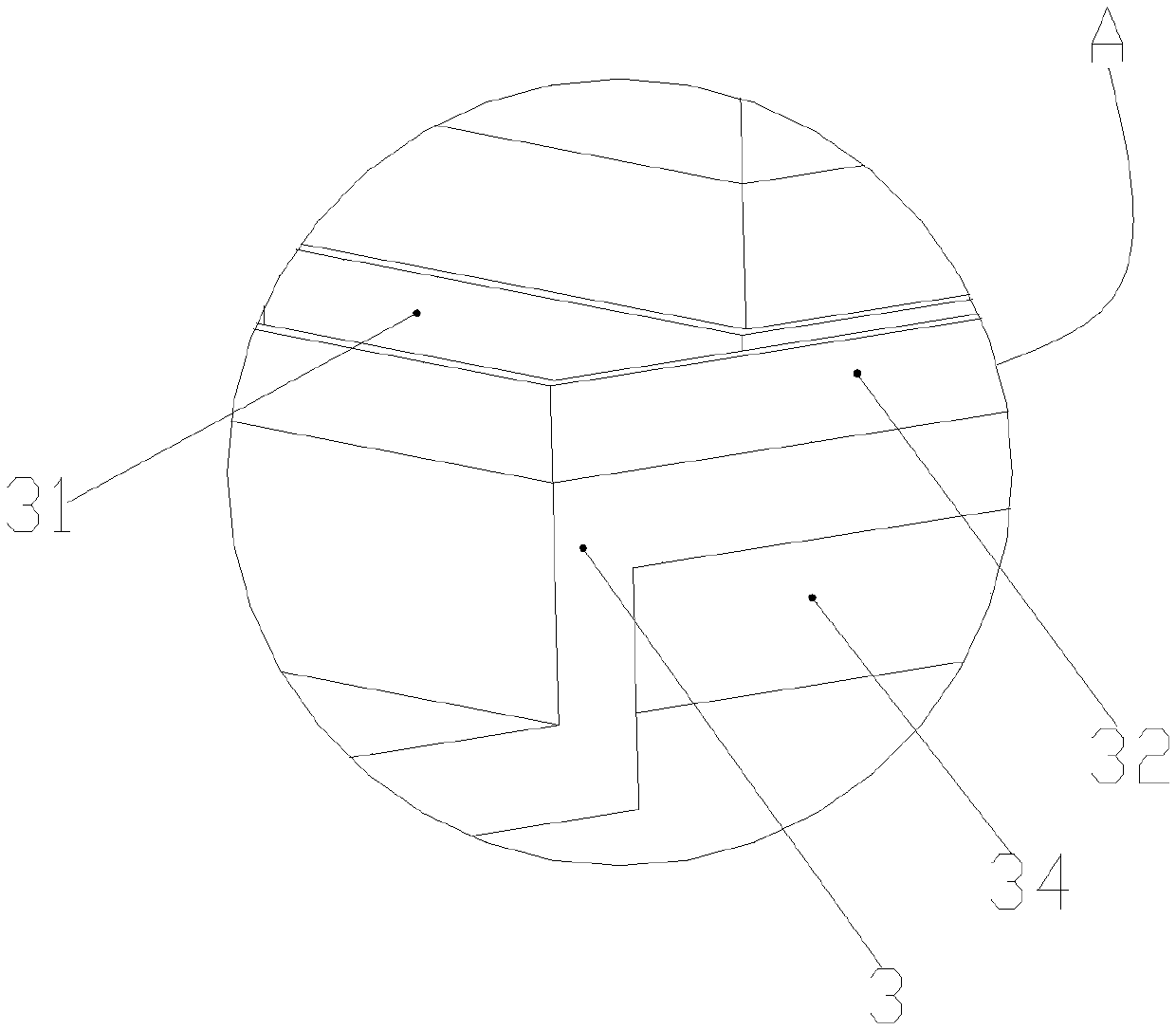

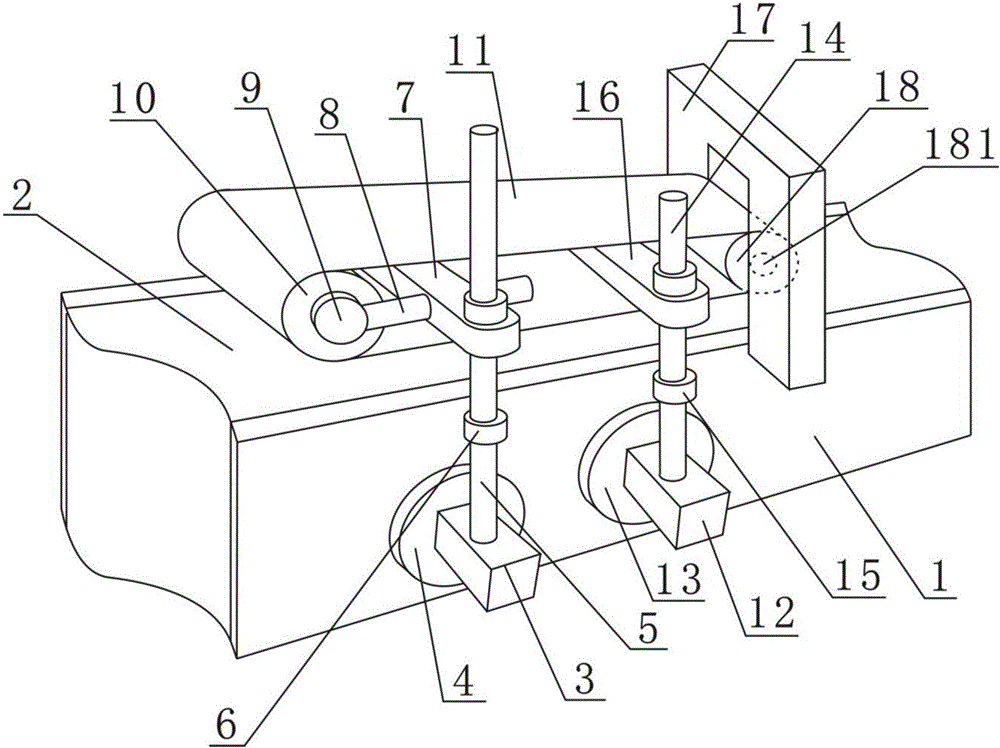

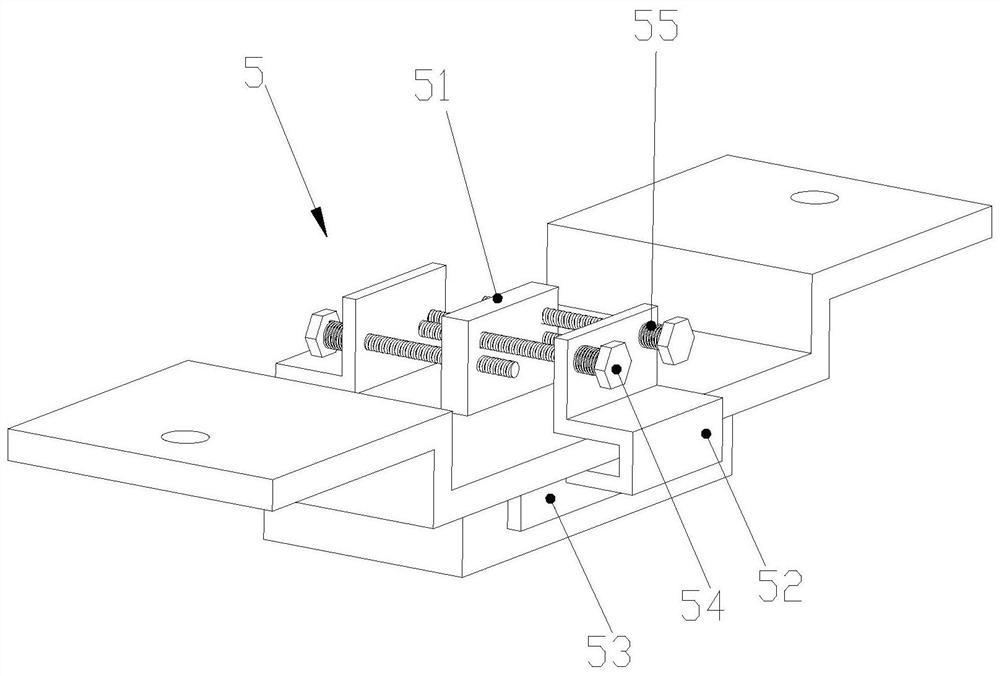

Adjustable locking mechanism

ActiveCN103307063AAdjustable positionAdjust extrusion forceFriction grip releasable fasteningsLocking mechanismEngineering

The invention relates to the technical field of locking mechanisms, in particular to an adjustable locking mechanism. The adjustable locking mechanism is adjustable in locking force and further comprises a locking screw, a spring and a check ring; a movable locking block, a fixed locking block, the spring and the check ring are embedded on a connecting shaft in sequence; one end of the spring is connected with the fixed locking block, and the other end of the spring is connected with the check ring; the locking screw is installed on the connecting shaft and connected with the check ring. The adjustable locking mechanism can be widely used for fastening or fixing elements.

Owner:JIANGXI HONGDU AVIATION IND GRP

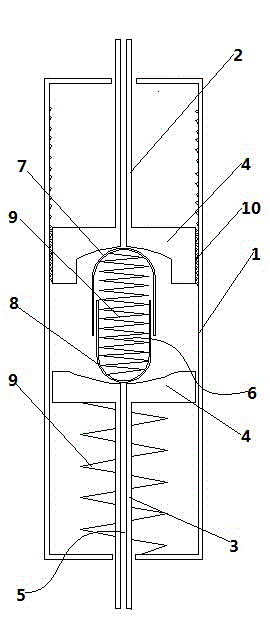

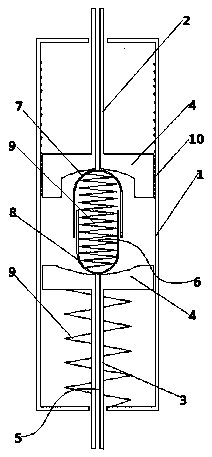

Agricultural water-saving drip irrigation head

InactiveCN104904565ASimple structureAdjust extrusion forceRoot feedersWatering devicesWater savingWater source

The invention relates to an agricultural water-saving drip irrigation head, which comprises a shell, an upper pressure pipe and a lower pressure pipe, wherein the upper and lower pressure pipes are arranged in the shell. The agricultural water-saving drip irrigation head is further provided with a spring cap head extruded between the upper and lower pressure pipes, wherein the upper pressure pipe is connected with a water source; the upper and lower ends of the spring cap head are pressed against the nearest ports of the upper and lower pressure pipes respectively. According to the agricultural water-saving drip irrigation head, the spring cap head forms extrusion contact with the upper and lower pressure pipes to form an incompletely-sealed structure between the upper and lower pressure pipes, so that water can seep under the condition of natural water pressure; by virtue of a threaded connecting structure, extrusion pressure between the spring cap head and the upper pressure pipe is conveniently regulated, and seepage flow on frosted surfaces can also be regulated; the lower pressure pipe contacts with the shell through a spring to form second group of spring pressure except the spring cap head, and acts together with the spring in the spring cap head to ensure that sealing effects of the frosted surfaces of an upper cap and a lower cap on openings of a water flow passage can be regulated, so that the seepage flow can be regulated.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

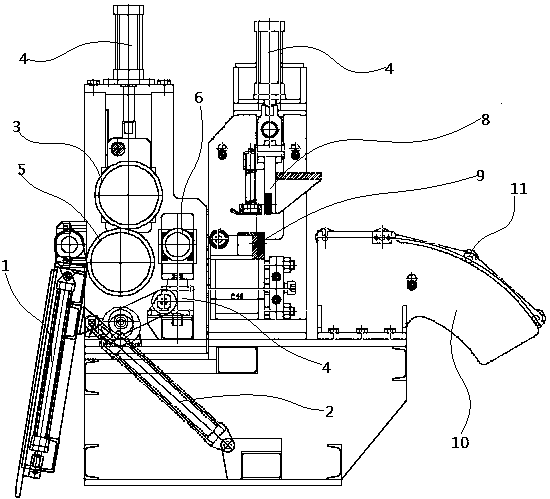

Efficient stamping die for automobile sheet metal part machining and using method thereof

InactiveCN113000710ARealize automatic toppingImprove processing efficiencyShaping toolsMetal-working feeding devicesElectric machineStructural engineering

The invention relates to the technical field of stamping dies, and discloses an efficient stamping die for automobile sheet metal part machining and a using method thereof. The efficient stamping die comprises a base, a supporting plate is fixedly connected to the upper surface of the base, a driving motor is fixedly installed on the surface of the supporting plate, and the output end of the driving motor is fixedly connected with a rotating shaft; a discharging mechanism is arranged in the base, a lower die base is welded to the upper surface of the base, and a feeding mechanism is arranged on the upper surface of the base. According to the efficient stamping die for automobile sheet metal part machining and the using method of the efficient stamping die, ejection columns and ejection plates in the die are driven to synchronously ascend through the ascending stroke in the stamping process, and therefore automatic material ejection in the sheet metal stamping process is achieved, manual operation is not needed, the overall sheet metal part machining efficiency is greatly improved, the circular inertia rotation of a rotary plate is utilized, and therefore the whole stamping process is more coherent and smoother.

Owner:杨柏

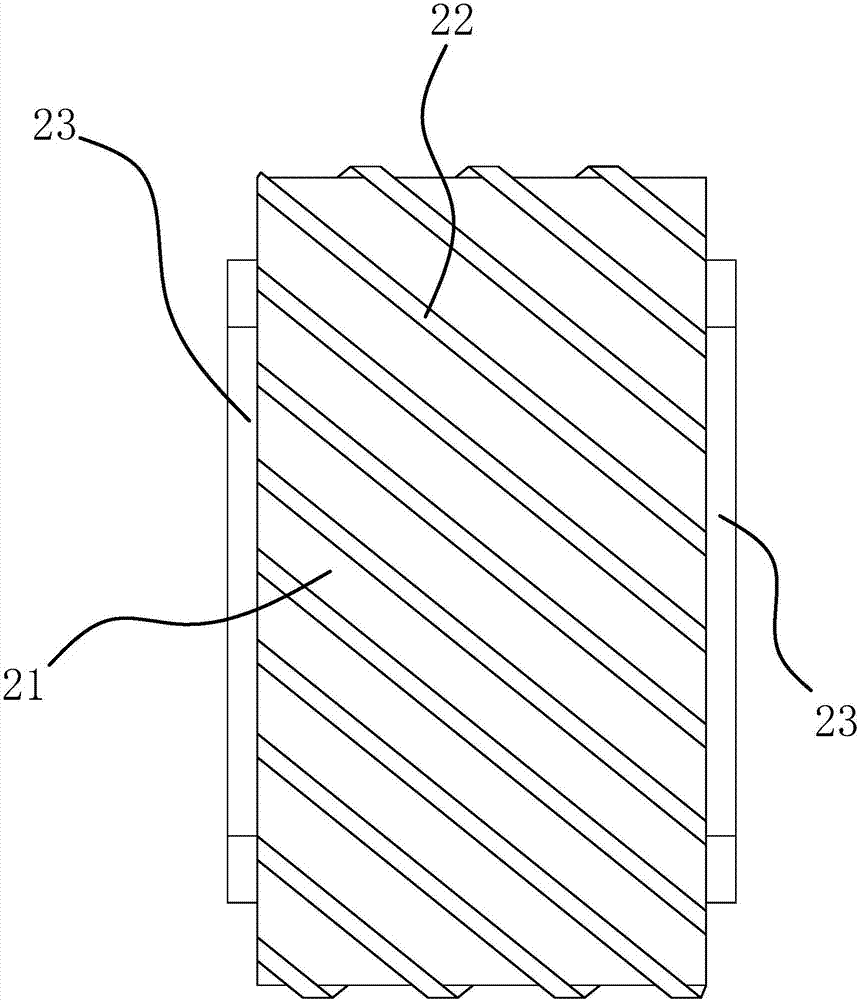

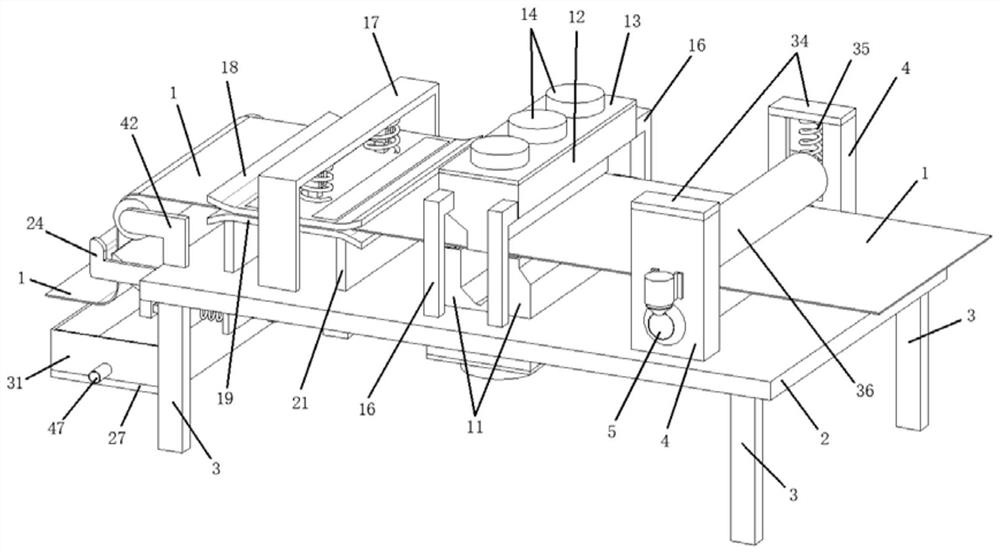

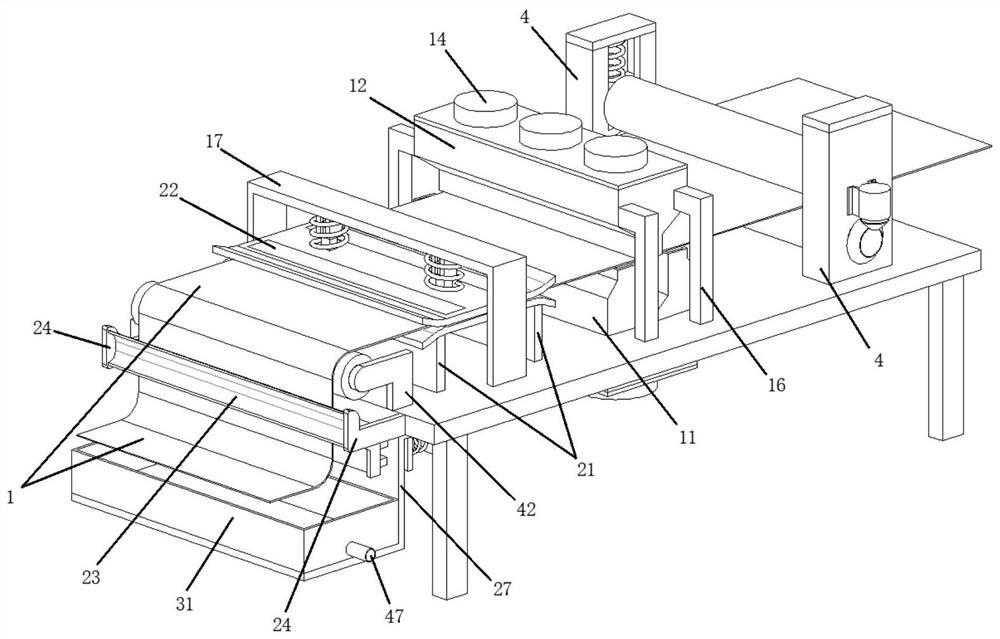

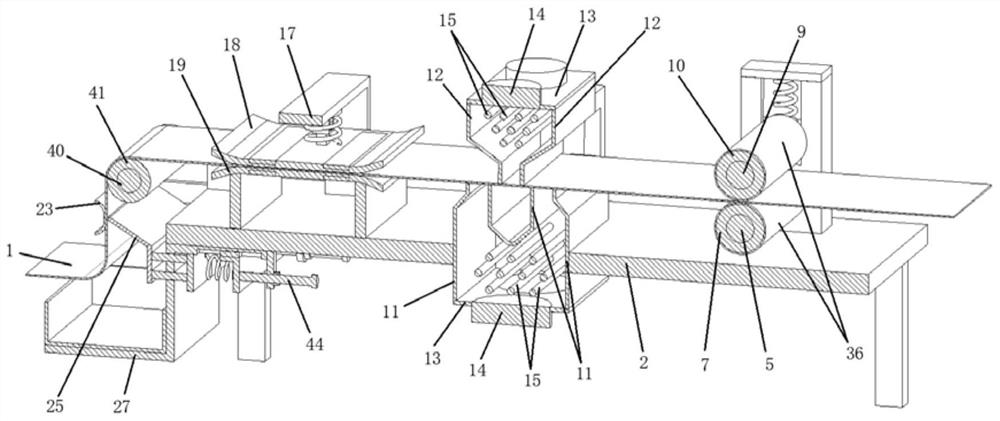

Double-sided drying equipment for polyester fabric production and processing

ActiveCN112647228AAvoid looseImprove stabilityLiquid/gas/vapor removal by squeezingTextile shapingPolyesterPolymer science

The invention relates to the technical field of cloth processing, in particular to double-sided drying equipment for polyester fabric production and processing. The double-sided drying equipment comprises polyester fabric, a processing table plate is arranged on one side of the polyester fabric, a plurality of supporting legs are fixedly arranged on one side of the processing table plate, two fixing columns are fixedly arranged on one side of the processing table plate, a driving shaft is arranged on one side of the processing table plate, through holes are formed in one sides of the fixing columns, the driving shafts are rotationally connected to the inner sides of the through holes, motors are arranged on one sides of the driving shafts and fixedly connected to one sides of the fixing columns, and transmission devices are arranged between the motors and the driving shafts. By arranging a feeding barrel, a pressing barrel, an automatic pressing device, a double-opening drying cover, a single-opening drying cover, the air inlet fan, an electric heating pipe, an upper ironing plate, a lower ironing plate, a spring A, a constant-temperature electric heating block, a water squeezing plate and a water squeezing frame, and the double-sided drying equipment for polyester fabric production and processing has the functions of automatic continuous processing, double-sided automatic drying, automatic ironing, automatic dewatering, squeezing force adjusting and the like.

Owner:吴江保利化纺有限公司

Tube film dewatering device of film blowing machine

The invention discloses a tube film dewatering device of a film blowing machine. The tube film dewatering device comprises a supporting frame, the supporting frame comprises a lower supporting plate,a supporting column and an upper supporting plate, the lower supporting plate and the upper supporting plate are fastened and connected through the supporting column, and first telescopic cylinders symmetrically distributed are arranged at the upper end of the lower supporting plate and the lower end of the upper supporting plate; and the top ends of the telescopic rods of the two first telescopiccylinders located at the upper end of the lower supporting plate and the lower end of the upper supporting plate are fastened and connected with a first supporting block and a second supporting block, a first limiting ring is arranged at the upper end of the first supporting block, and a clamping unit is arranged at the upper end of the second supporting block. A tube film device needing to suckthe surface water is placed between sponge in a clamping block and sponge clamped in the first limiting ring, the first telescopic cylinder is adjusted, the sponge is attached to the tube film surface, and water sucking is conducted on the tube film.

Owner:HEFEI XINDA MEMBRANE TECH

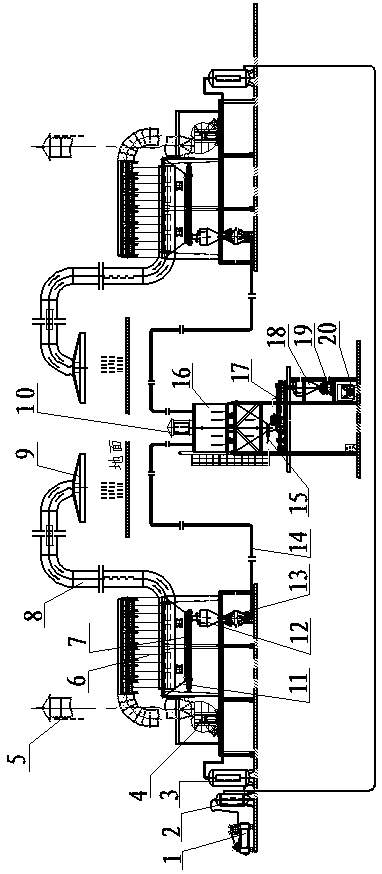

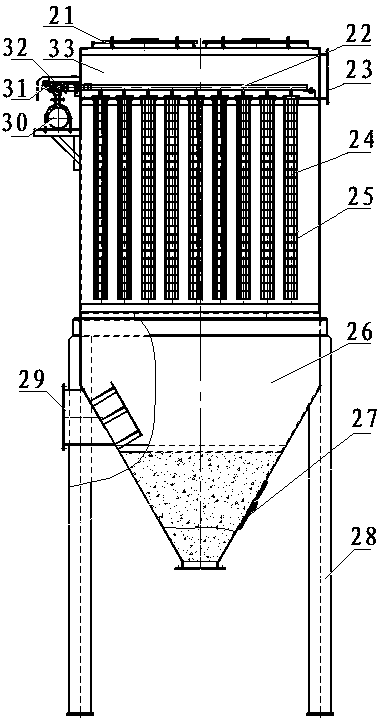

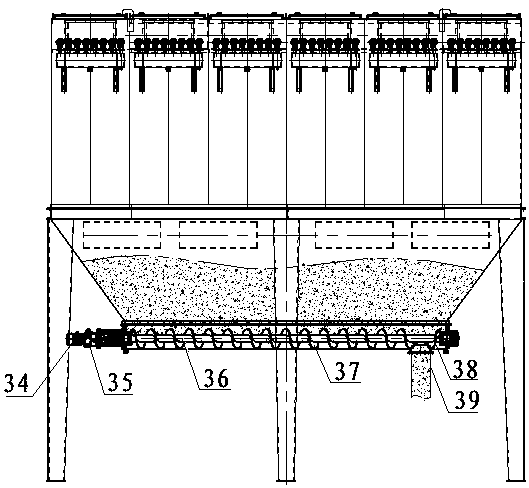

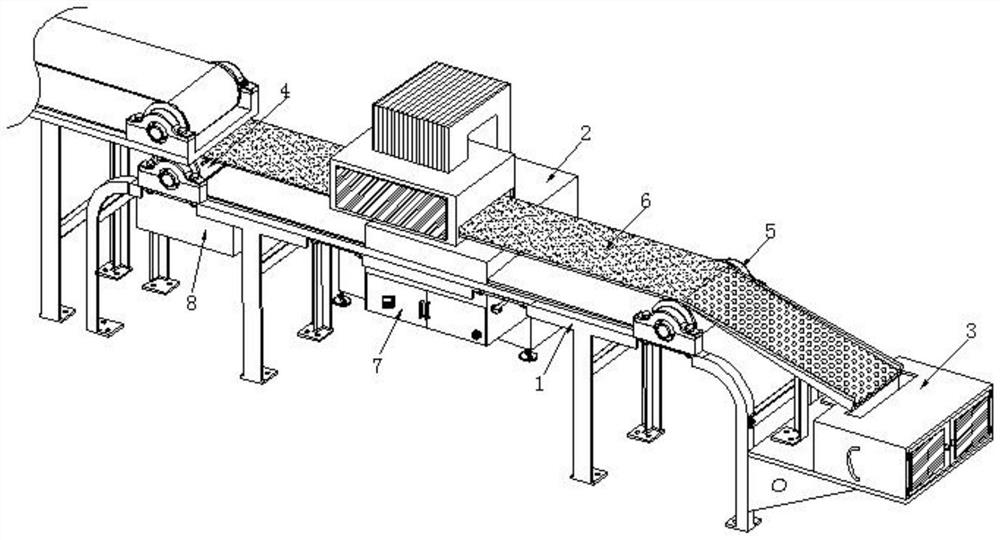

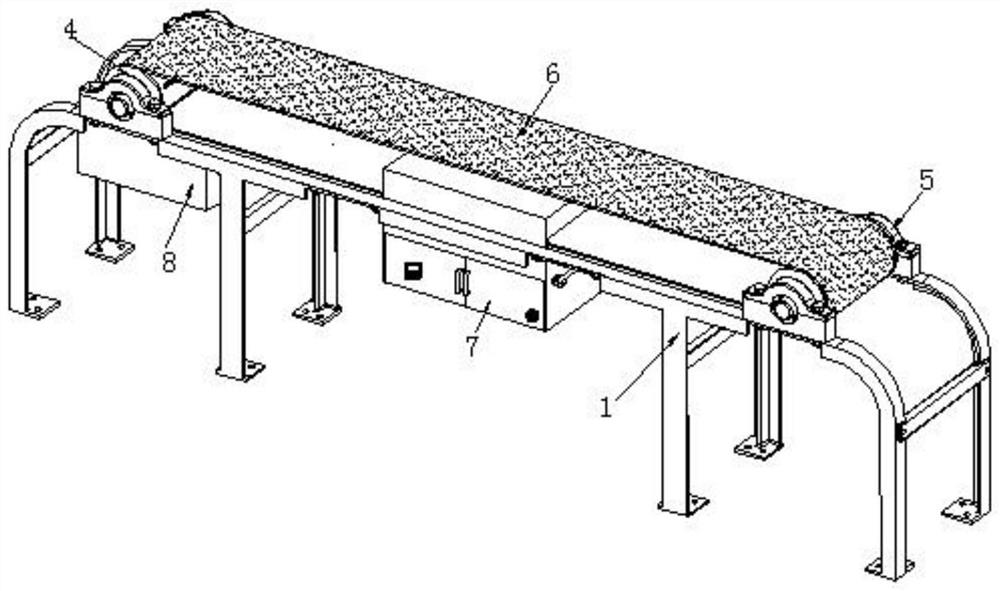

Ash processing production line and processing method

InactiveCN107469491AAvoid accumulationAvoid cakingHuman health protectionDispersed particle filtrationProduction lineFailure rate

The invention discloses an ash processing production line and a processing method. The ash processing production line comprises an ash collecting system, an ash feeding system, an ash pressure feeding system, a stirring system and a ball making system, wherein the ash collecting system is connected with the ash feeding system through a pipeline; a sealing pad is arranged at a joint of the pipeline; the ash pressure feeding system is connected with the ash feeding system and the stirring system in turn; the stirring system is connected with the ball control system. The ash processing production line is characterized by low cost, low noise, high degree of automation and low failure rate; the production line runs under a fully sealed state; flying dust is avoided and the technical problem of dust pollution to the environment caused by the ash is thoroughly solved.

Owner:青岛天汇铸造机械有限公司

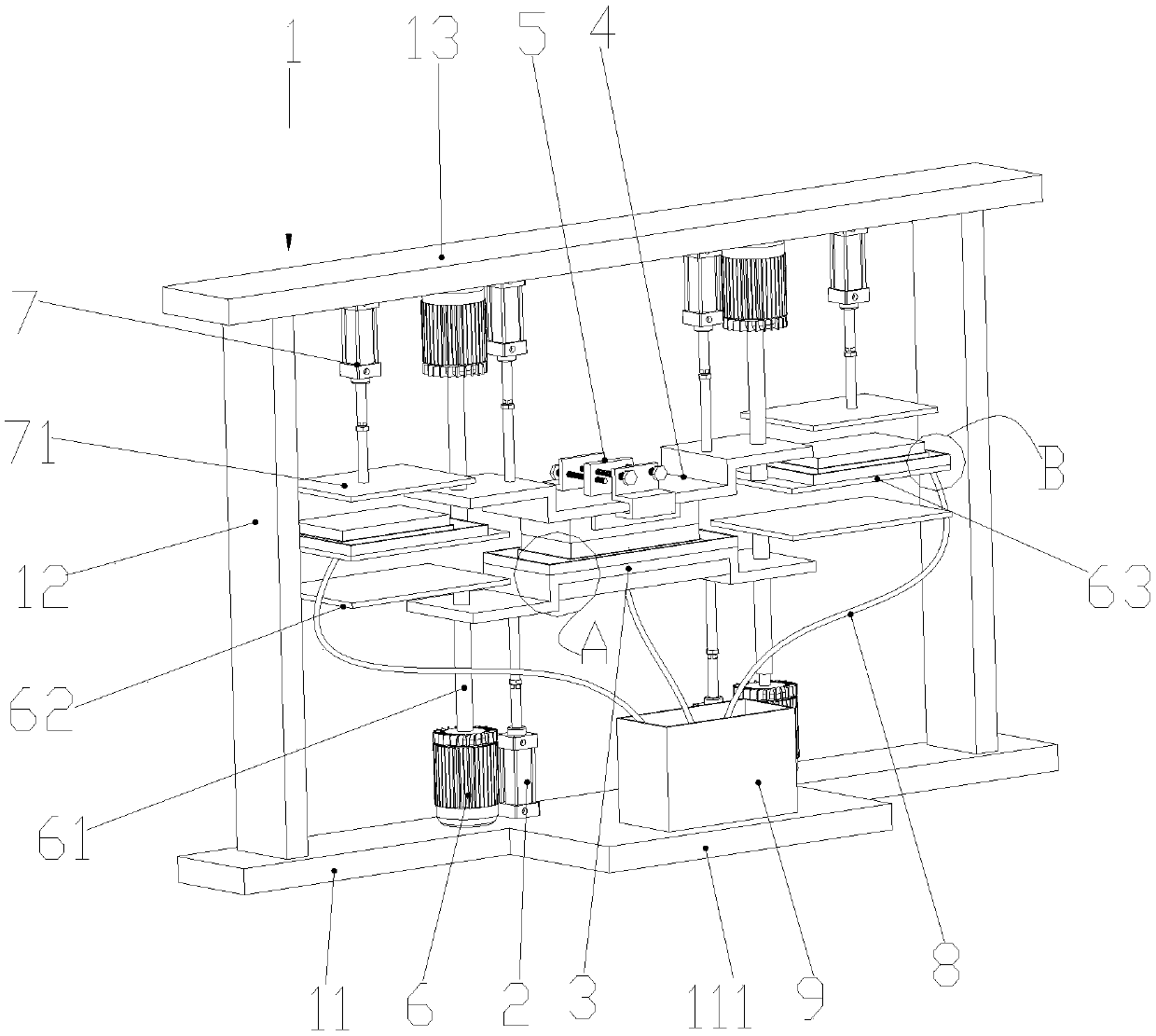

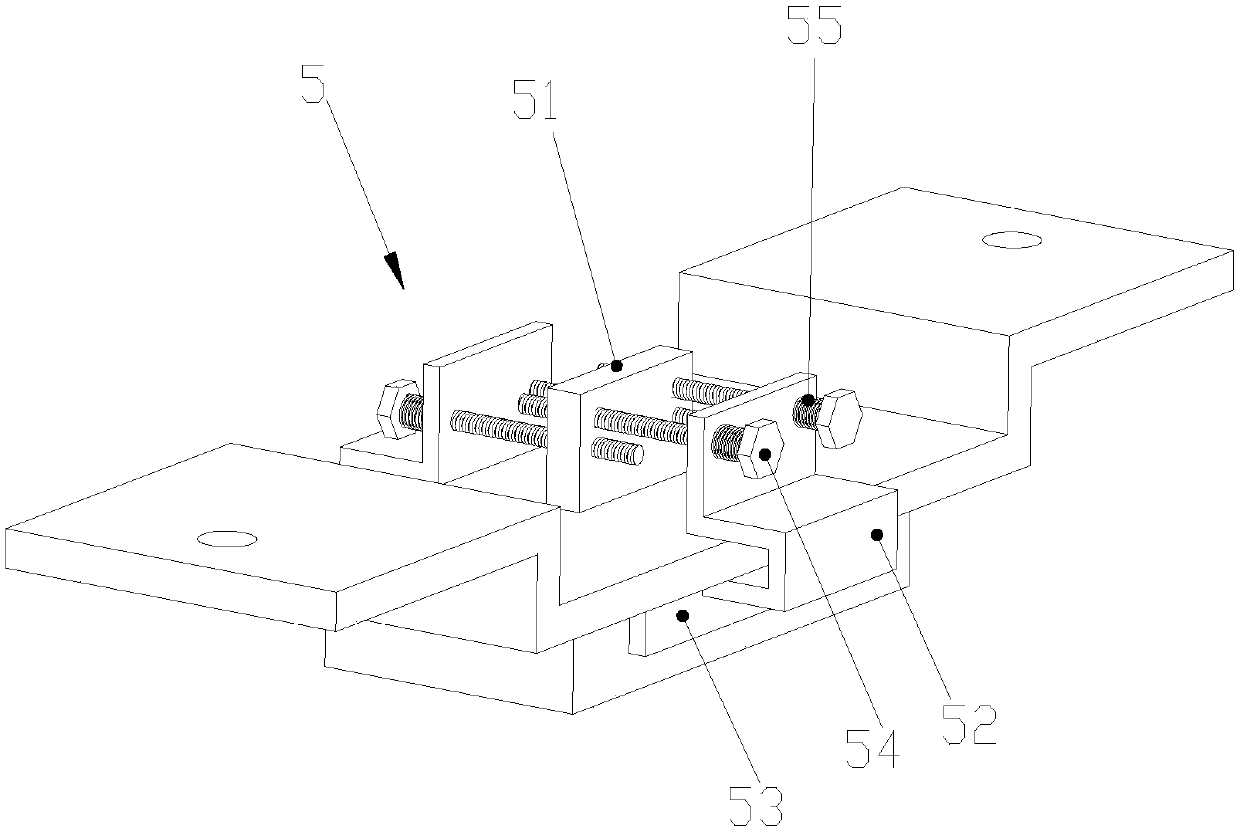

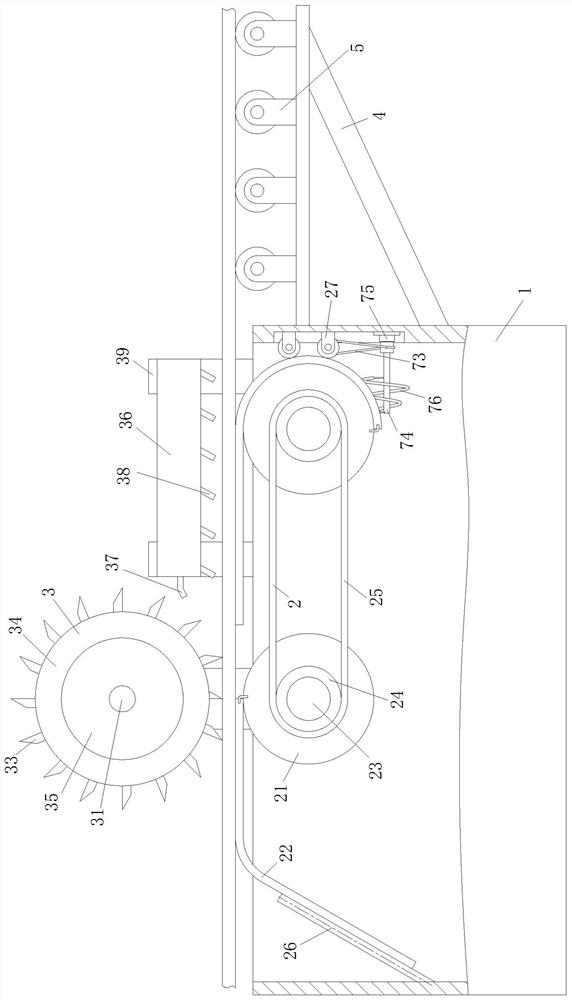

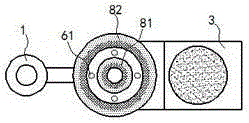

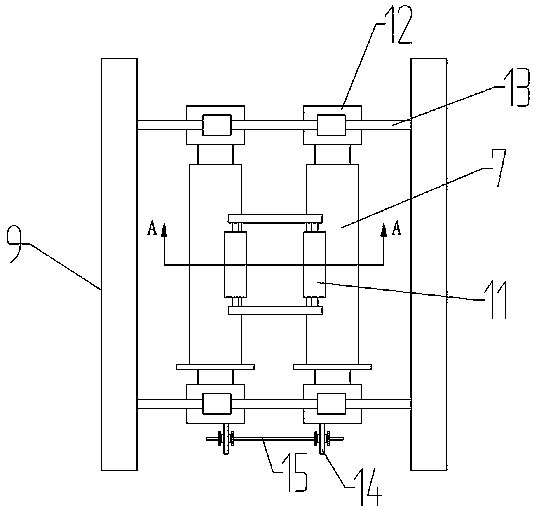

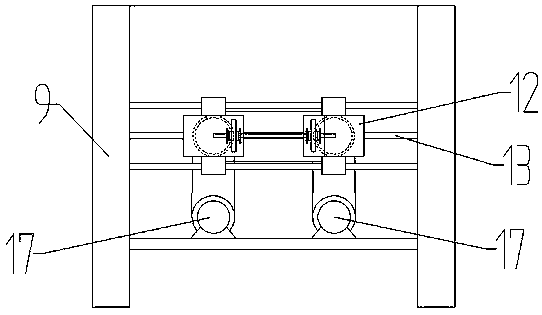

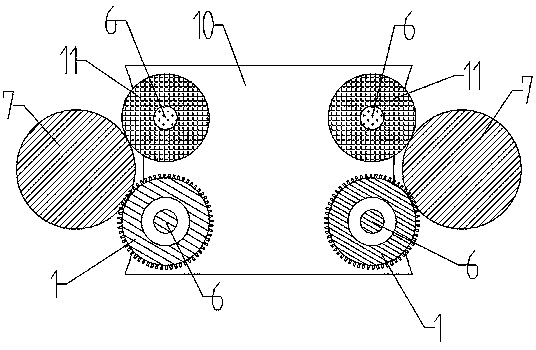

Double-bottle-pressing infusion bottle leakage detecting system used for infusion bottle conveying line

ActiveCN106809594ASatisfy the requirements of flow water leak detection operationEasy to operateDetection of fluid at leakage pointConveyorsBiomedical engineeringAssembly line

The invention discloses a double-bottle-pressing infusion bottle leakage detecting system used for an infusion bottle conveying line. The system comprises the infusion bottle conveying line, the infusion bottle conveying line is provided with a transmission belt, a first bottle-pressing leakage detecting system body and a second bottle-pressing leakage detecting system body. The first bottle-pressing leakage detecting system comprises a supporting base A, a supporting screw rod A and a bottle-pressing cross beam A, the bottle-pressing cross beam A is fixedly provided with a connection rod, a bearing is arranged at the end of the connection rod, a bottle-pressing roller driven shaft is arranged in the bearing, and a bottle-pressing roller is arranged on the outer portion of the bottle-pressing roller driven shaft; the second bottle-pressing leakage detecting system comprises a supporting base B, a supporting screw rod B and a bottle-pressing cross beam B. The infusion bottle conveying line is provided with a driving roller power device, a driving roller is fixedly arranged on the outer portion of a driving roller power shaft of a motor of the driving roller power device, and a bottle-pressing endless belt is arranged between the driving roller and the bottle-pressing roller. Assembly line leakage detecting work is conducted on infusion bottles by means of two bottle-pressing mechanisms, and the assembly line leakage detecting work is achieved.

Owner:SICHUAN KELUN PHARMA CO LTD

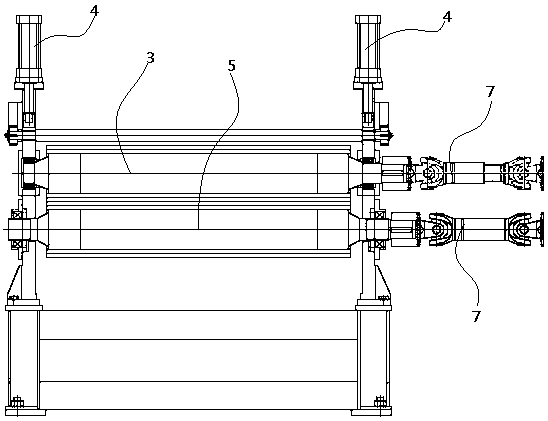

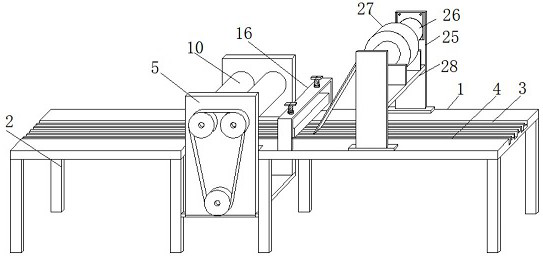

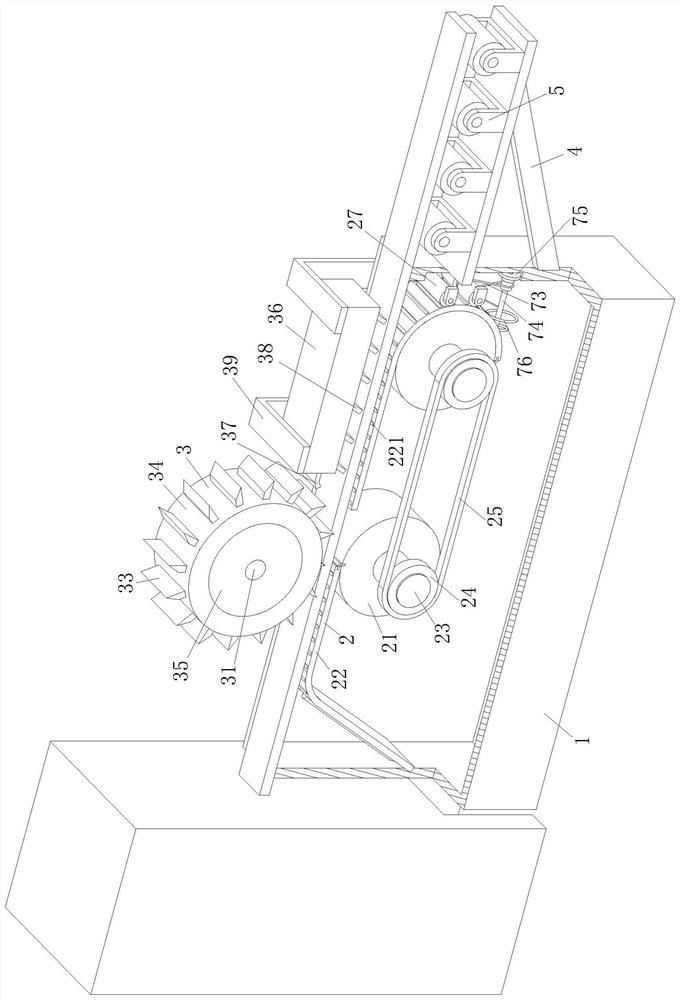

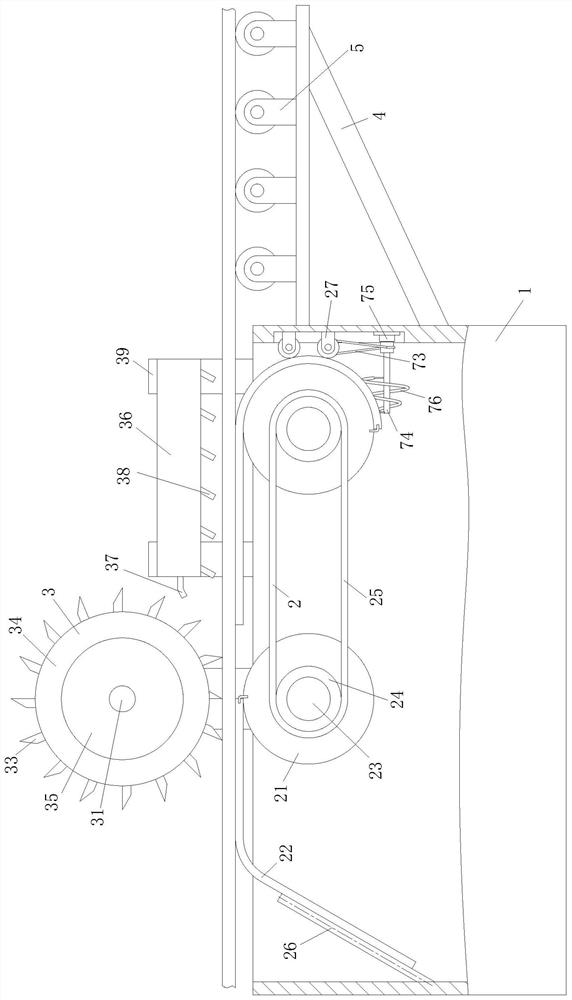

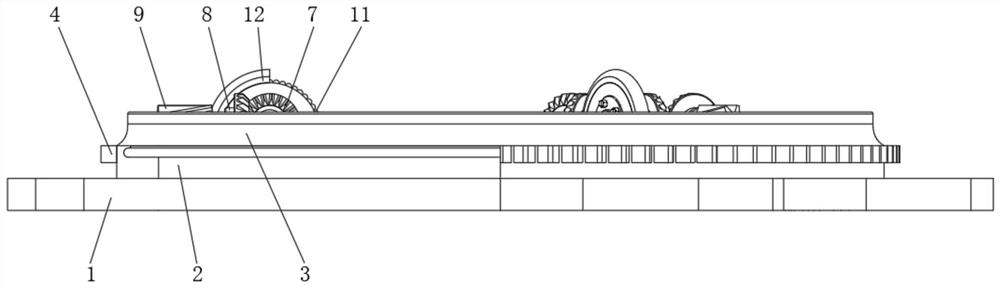

Unwinding steel coil leveling machine

The invention discloses an unwinding steel coil leveling machine, which comprises a guiding plate, a three-roller leveling mechanism and a discharging slope which are sequentially arranged in the running direction of a steel plate. The unwinding steel coil leveling machine is characterized in that the three-roller leveling mechanism comprises an adjusting roller and a first squeezing roller and asecond squeezing roller tangent to each other, wherein one side of the tangential line of the first squeezing roller and the second squeezing roller tangent to each other is provided with the adjusting roller. The two ends of the adjusting roller are respectively connected with a displacement driving device. The two displacement driving devices synchronously drive the adjusting roller to displacein the direction perpendicular to a self axis. The two ends of the first squeezing roller are respectively connected with a squeezing driving device. The two squeezing driving devices synchronously press the first squeezing roller to the second squeezing roller.

Owner:江苏科创机器人有限公司

Anti-wrinkle compound machine

The invention relates to an anti-wrinkle compound machine which comprises a base frame, two material rollers are arranged at one end of the base frame, the base frame is provided with a glue spreading roller, a glue uniformizing roller and a combining roller, the base frame is connected with two compound supporting rods, and the two compound supporting rods are jointly and rotationally connected with a lower compound roller. The two composite supporting rods are jointly and fixedly connected with a transverse rod, the transverse rod is connected with a connecting rod, a plurality of supporting frames are arranged at the bottom of the connecting rod, each supporting frame is rotationally connected with an upper composite roller, the upper composite rollers and the lower composite rollers are arranged in parallel, each upper composite roller is provided with a cavity, and the cavities of the upper composite rollers are used for containing hot water. An abutting device used for enabling the upper composite roller to move towards the lower composite roller is arranged between each supporting frame and the corresponding connecting rod, and the effects that it is guaranteed that when the composite rollers extrude a thin film, the temperature of the thin film can be in a stable state, and a finished product is prevented from wrinkling are achieved.

Owner:青岛萱通工贸有限公司

An anti-deformation aluminum profile conveying device

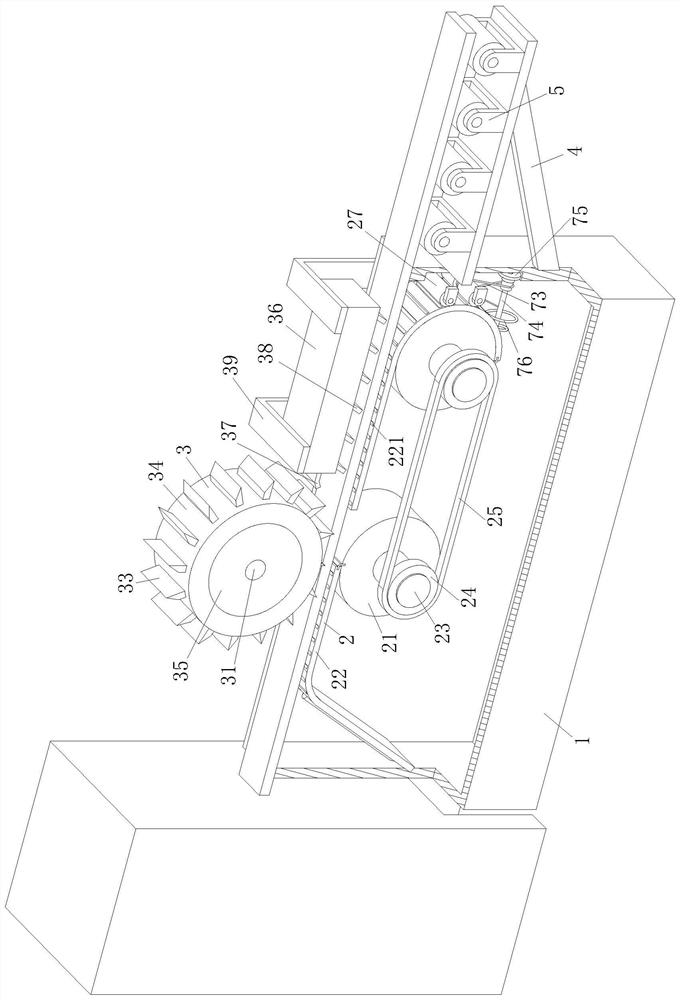

ActiveCN111717611BIncrease the support areaAvoid deformationLoading/unloadingConveyor partsEngineeringSprocket

The invention belongs to the technical field of conveying devices, in particular to an anti-deformation aluminum profile conveying device, which includes a supporting box, a lower supporting part, a cooling part, an inclined bracket and driven rollers; the lower supporting part includes winding wheels, elastic metal belt, supporting shaft, sprocket, chain, guide rod and friction wheel; in the present invention, the elastic metal belt at the free end is evenly attached to the lower surface of the just-formed aluminum profile, thereby increasing the rigidity of the just-formed aluminum profile. Support area, thereby preventing the deformation of the newly formed aluminum profile due to its low strength, thereby improving the quality of the newly formed aluminum profile during the transportation process, thereby improving the manufacturing accuracy of the aluminum profile; when the free end of the elastic metal belt falls Into the cooling liquid in the support box, and then realize the cooling of the elastic metal belt, and then ensure the elastic metal belt has stable elasticity, and then ensure the supporting effect of the elastic metal belt, and then improve the manufacturing quality of the aluminum profile.

Owner:佛山市金浩联铝业有限公司

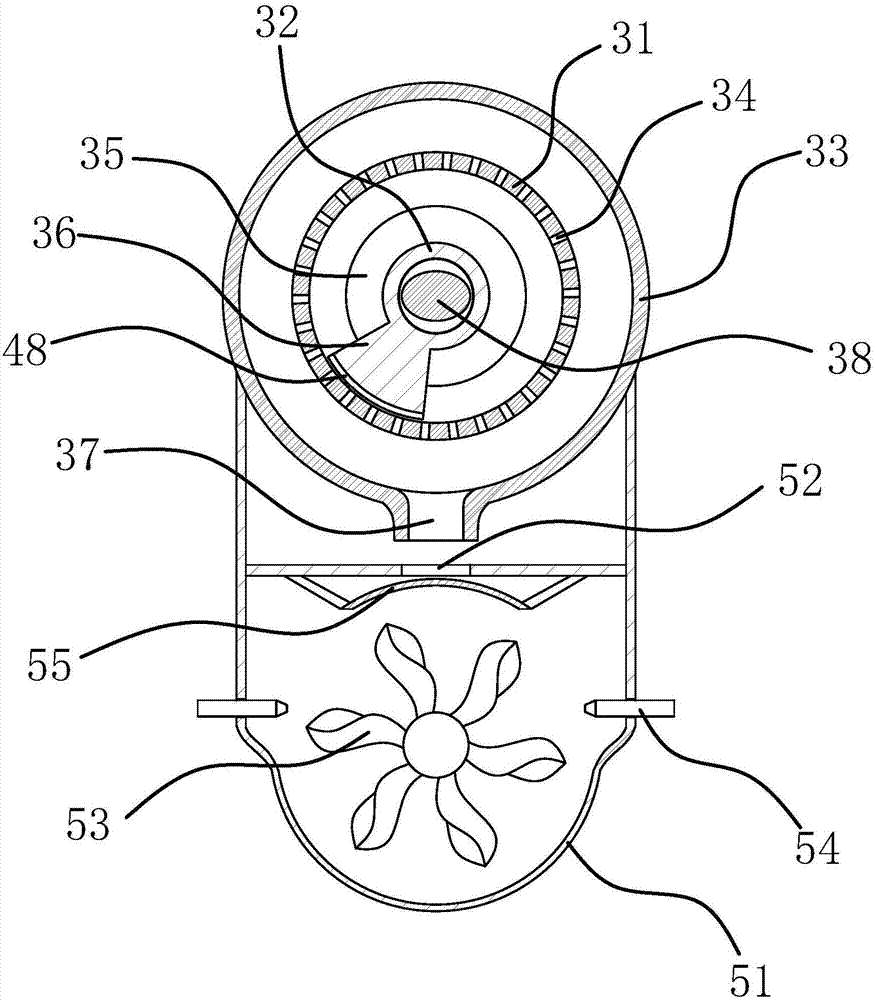

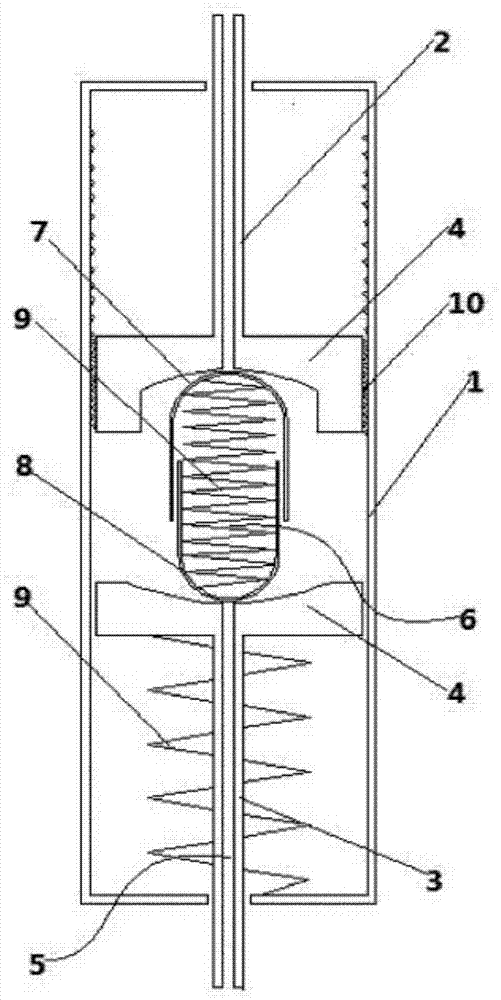

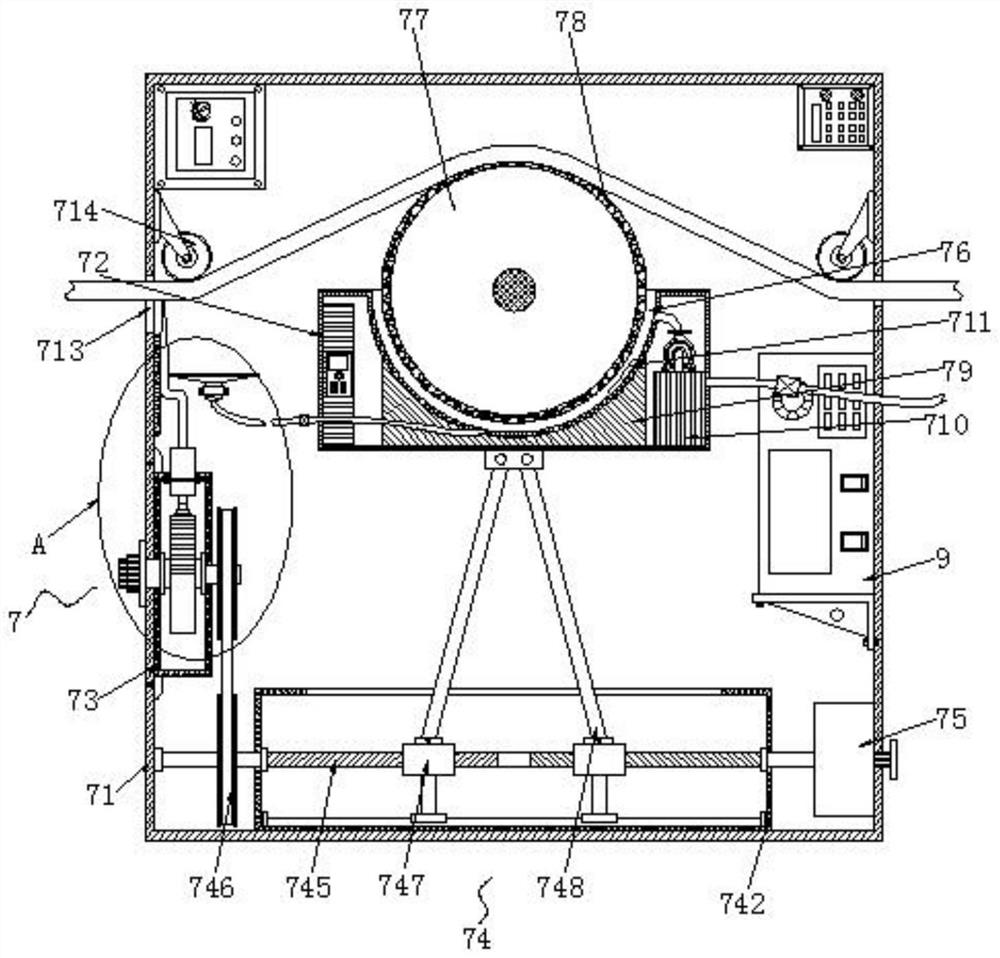

Electromagnetic briquetting machine

ActiveCN105584075BPressing to achieveExtended service lifePress ramRotary pressEngineeringConveyor belt

The invention relates to an electromagnetic briquetting machine, which includes a feeding end, a pressing bin and a conveyor belt; a discharge plate is installed on the side wall of the pressing bin facing the discharging end; A pressurizing screw is also installed on the top of the press-fitting chamber; a conductive sheet is fixedly installed on the upper end of the pressurizing thread, and conductive posts are rotationally symmetrically distributed on the conductive sheet; the upper ends of each of the conductive posts are fixed on the conductive ring; the conductive ring and the conductive sheet can rotate synchronously under the drive of the conductive column; the conductive sheet and the conductive ring are respectively connected to the positive and negative poles of the DC power supply; installed on the inner ring of the conductive ring There is an inner permanent magnet cylinder, and an outer permanent magnet cylinder is installed on the outer ring of the conductive ring; the opposite polarities of the inner permanent magnet cylinder and the outer permanent magnet cylinder attract each other; the briquetting machine is compact in structure, Small in size, it can press and pack chips efficiently, and is suitable for pressing and packing of various chips.

Owner:江苏百代节能建材有限公司

Agricultural dropper

InactiveCN106888933AAdjust extrusion forceAdjustable tightnessWatering devicesCultivating equipmentsWater sourceWater flow

The invention relates to a drip irrigation head for agriculture, comprising: a housing, an upper pressure tube and a lower pressure tube installed inside the housing, and a spring cap squeezed between the upper pressure tube and the lower pressure tube , the upper pressure tube is connected to a water source, and the upper end and the lower end of the spring cap are against the nearest ports of the upper pressure tube and the lower pressure tube respectively. The spring cap head forms an incomplete sealing structure between the upper pressure tube and the lower pressure tube through the squeeze contact between the upper pressure tube and the lower pressure tube, so that the water can also seep out under the condition of natural water pressure ;The upper pressure tube can easily adjust the extrusion force between the spring cap head and the pressure tube through the threaded connection structure, and can also adjust the seepage amount of the frosted surface; the lower pressure tube contacts the shell through the spring, which forms the first Two sets of spring pressure, which work together with the spring in the spring cap head to ensure that the sealing effect of the frosted surface of the upper cap and the lower cap on the water flow channel opening can be adjusted, so that the seepage volume can be adjusted.

Owner:BADONG FENGTAI AGRI SPECIALIZED COOP

Electromagnetic briquetting machine

The invention relates to an electromagnetic briquetting machine. The electromagnetic briquetting machine comprises a feeding end, a press-fitting bin and a conveying belt. A discharging plate is arranged at the position, directly facing the discharging end, of the side wall of the press-fitting bin; a pressurizing screw rod is further arranged on the upper portion of the press-fitting bin, and a conducting strip is fixedly mounted at the upper end of the pressurizing screw rod; conducting columns are rotatably and symmetrically distributed on the conducting strip, and a conducting ring is fixed to the upper end of each conducting column; the conducting rings and the conducting strip can be driven by the conducting columns to synchronously rotate; the conducting strip is connected with the positive electrode and the negative electrode of a direct-current power source, and the conducting rings are connected with the positive electrode and the negative electrode of the direct-current power source; an inner permanent magnet cylinder is arranged on the inner rings of the conducting rings, and an outer permanent magnet cylinder is mounted on the outer rings of the conducting rings; and the opposite cylinder faces of the inner permanent magnet cylinder and the outer permanent magnet cylinder are in heteropole attraction. The electromagnetic briquetting machine is compact in structure, small and exquisite in size, capable of carrying out efficient press fitting on chippings and suitable for press fitting of multiple kinds of chippings.

Owner:江苏百代节能建材有限公司

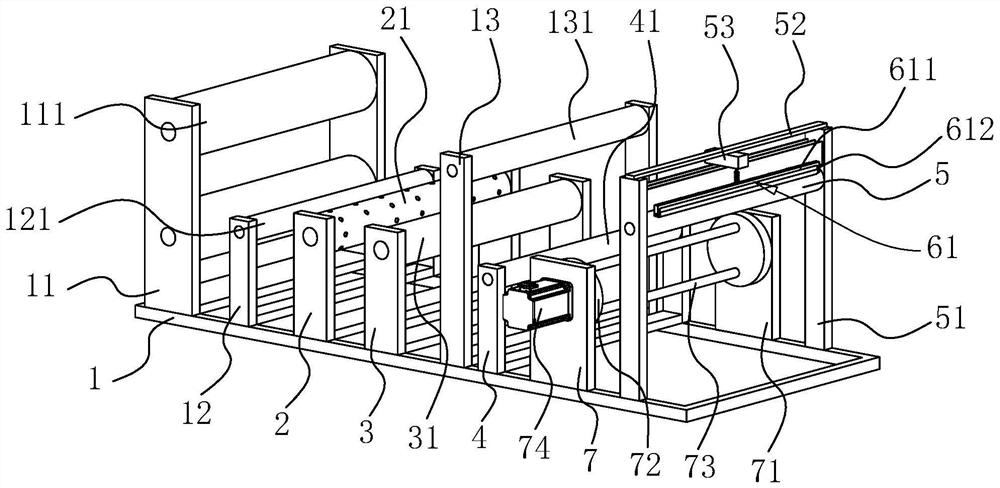

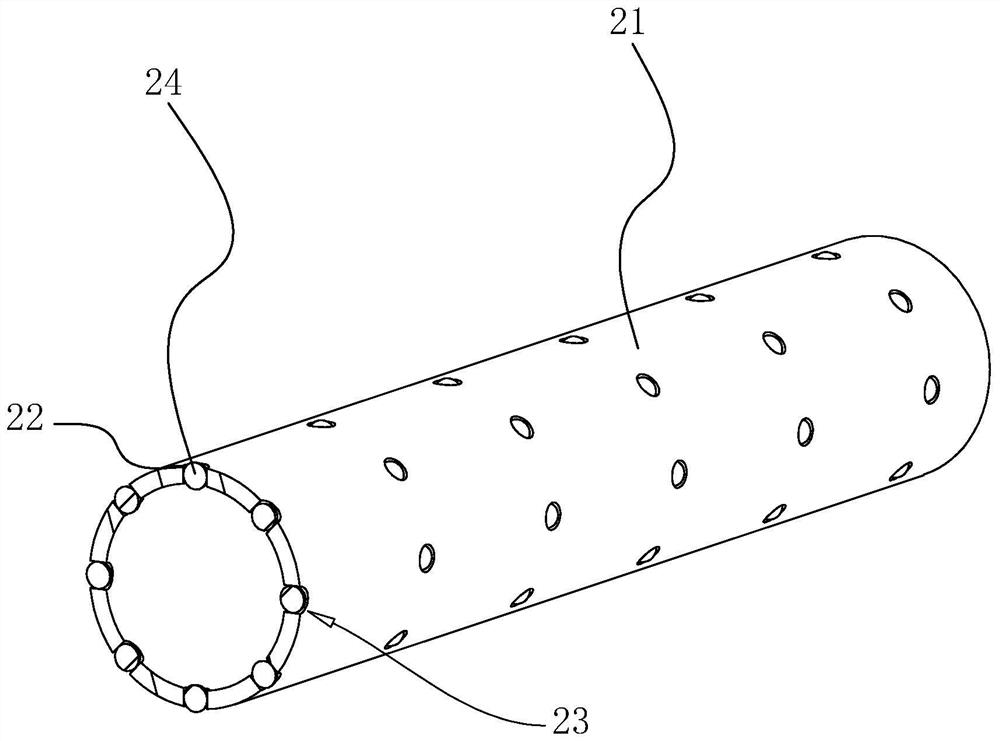

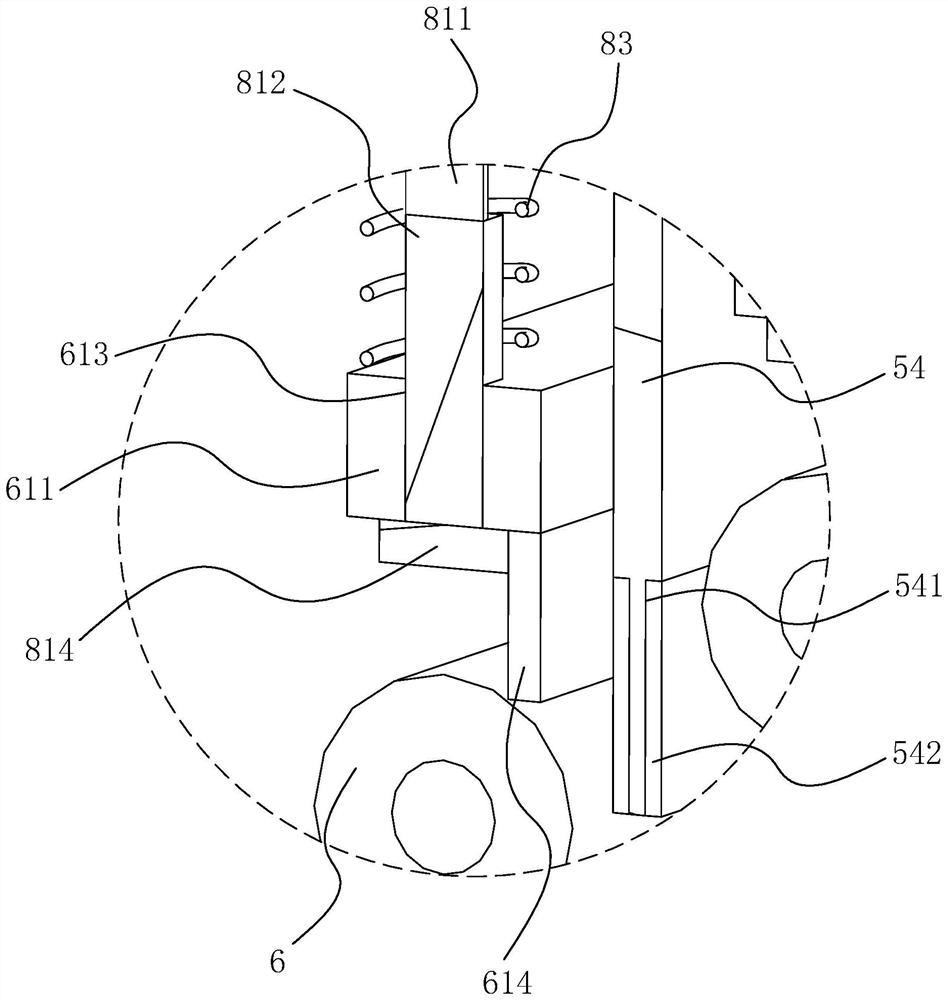

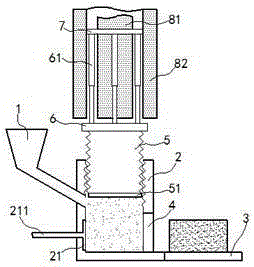

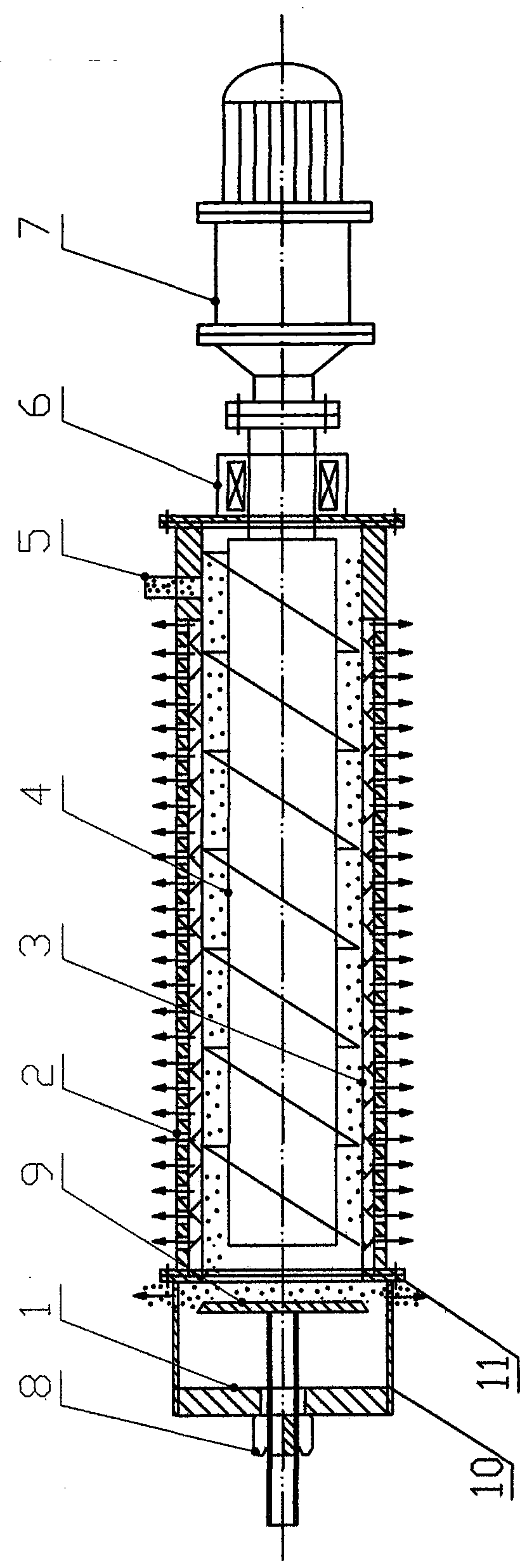

High-efficiency dewatering machine provided with filtering screen and utilizing strong spiral force for extrusion

Disclosed is a high-efficiency dewatering machine provided with a filtering screen and utilizing strong spiral force for extrusion. The high-efficiency dewatering machine is composed of a fixing plateand bracket, a perforated casing pipe, the filtering screen, an auger, a feeding pipe, a blind plate and bearing base and a speed reducer; the filtering screen is arranged on the inner wall of the perforated casing pipe and tightly fits the inner wall; a flange at one end of the perforated casing pipe is fixedly provided with the fixing plate and bracket through screws; a fixing plate at the outer end of the fixing plate and bracket is provided with an adjusting screw; a flange at the other end of the perforated casing pipe is fixedly provided with the blind plate and bearing base through a screw; the perforated casing pipe is internally provided with the auger, and the auger is fixed through a bearing of the blind plate and bearing base; the outer end of the auger is connected with the speed reducer through the flange; the feeding pipe is arranged at the outer side, close to the blind plate and bearing base, of the perforated casing pipe. According to the high-efficiency dewatering machine, filtering is conducted through strong-force pushing of the auger and compression of a screw rod jacking cover, the pressure is 1 Mpa / cm<2> or above, various water containing substances such assewage sludge and oil sludge are strongly pressed for dewatering, the dewatered sewage sludge is discharged through the gap between the auger and a screw rod jacking plate, the efficiency is high, and the labor is saved.

Owner:李艺 +3

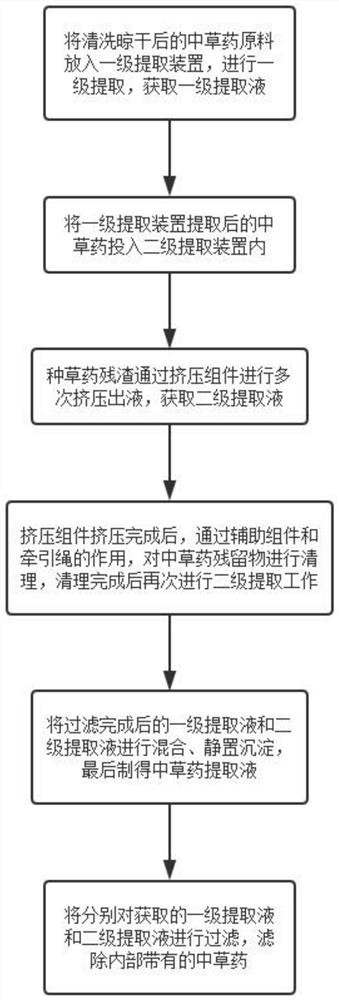

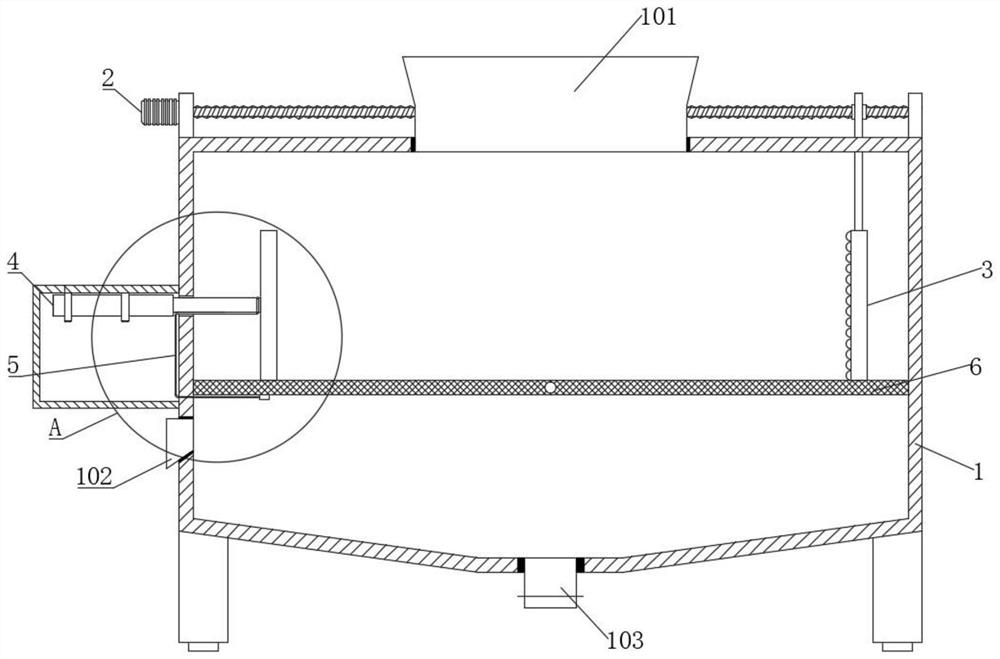

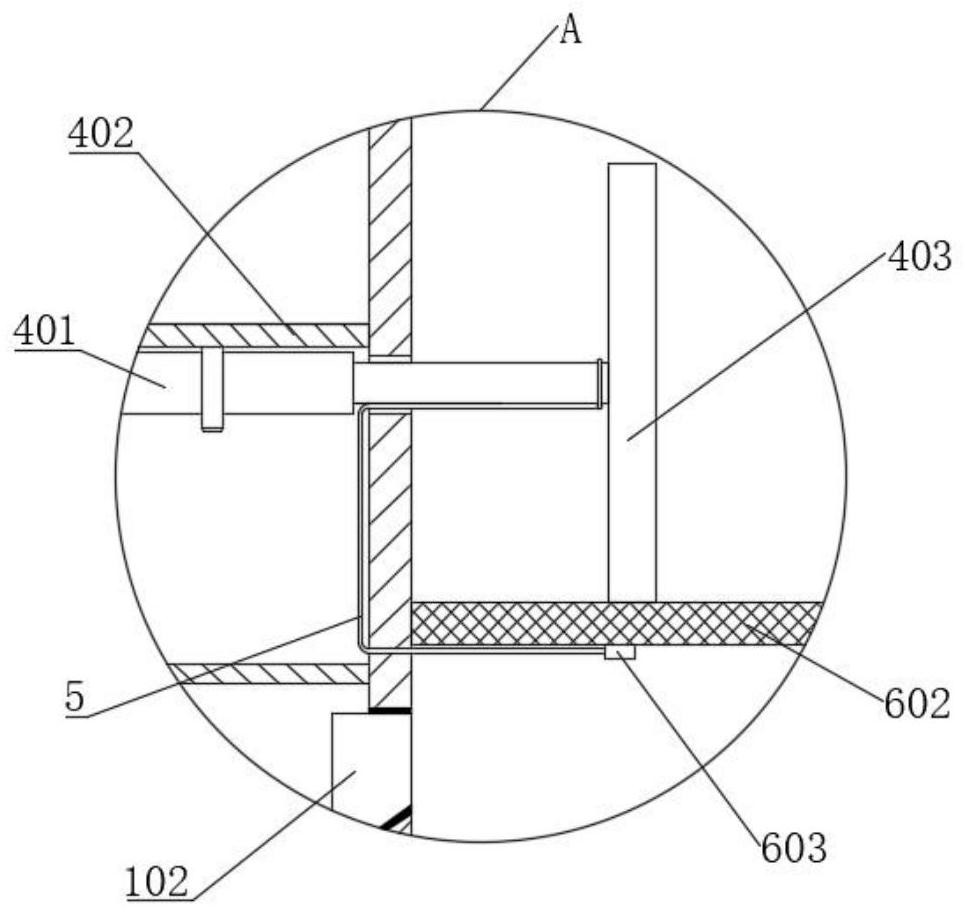

Chinese herbal medicine cosmetic raw material extraction method and device thereof

InactiveCN112675569AEasy to handleQuality improvementSolid solvent extractionFiltration circuitsHerb medicineProcess engineering

The invention discloses a Chinese herbal medicine cosmetic raw material extraction method and a device thereof, belongs to the field of cosmetic processing, and the method comprises the following steps: putting cleaned and air-dried Chinese herbal medicine raw materials into a primary extraction device, and performing primary extraction to obtain a primary extracting solution; putting the Chinese herbal medicines extracted by the primary extraction device into a secondary extraction device; and squeezing the herbal medicine residues for multiple times through a squeezing assembly to obtain a secondary extracting solution. Through cooperation of the auxiliary assembly and the traction rope, extracted Chinese herbal medicine residues can be effectively treated, the treatment efficiency is improved, the cleanliness of the filter plate is effectively guaranteed, the filter plate is effectively prevented from being blocked, the Chinese herbal medicine extraction quality is improved, and through mixing and standing of a first-stage extracting solution and a second-stage extracting solution, a complete Chinese herbal medicine extracting solution is effectively obtained, Chinese herbal medicine extracting efficiency and extracting proportion are improved, and Chinese herbal medicine utilization rate is increased.

Owner:江苏瀚空智能科技有限公司

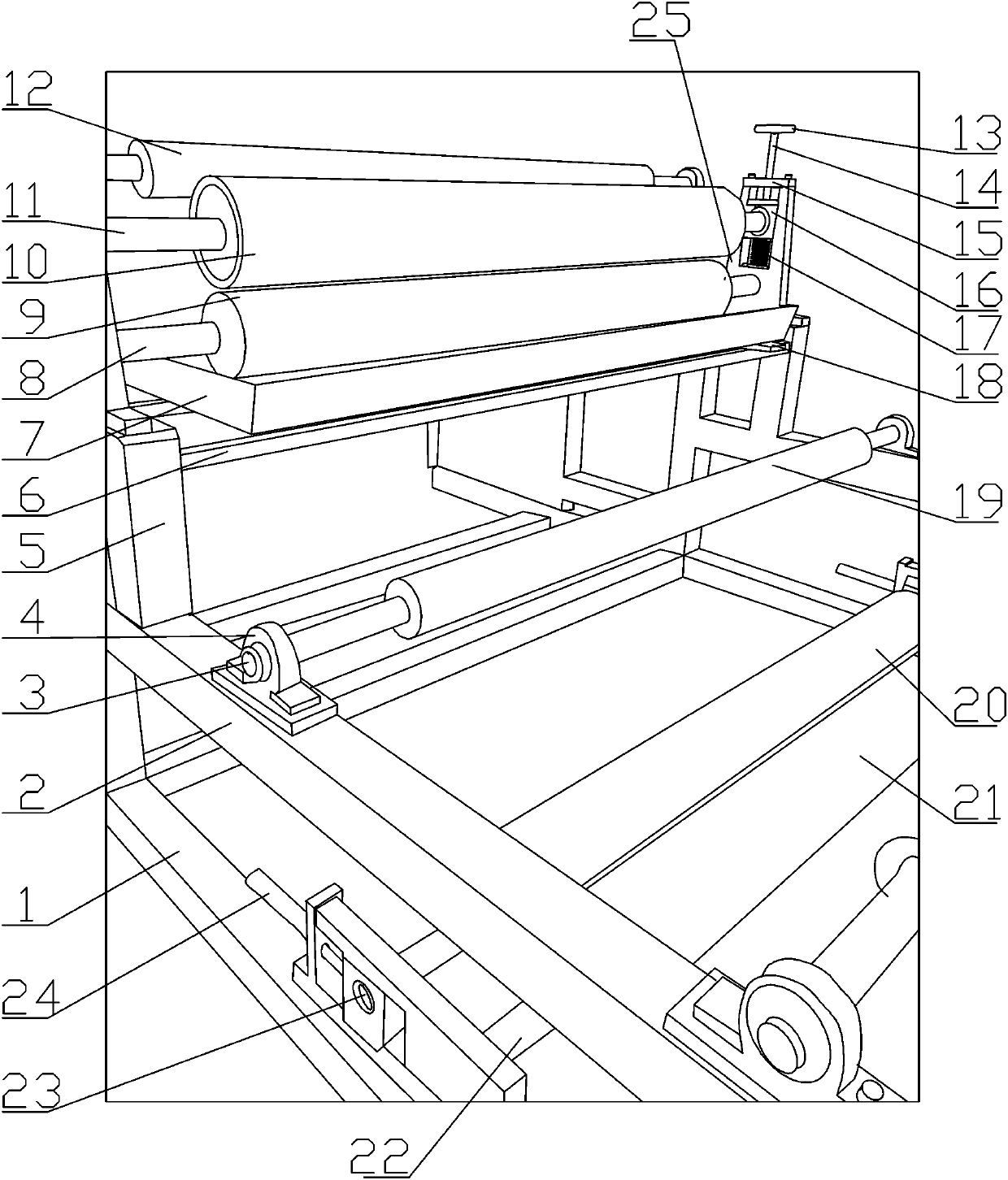

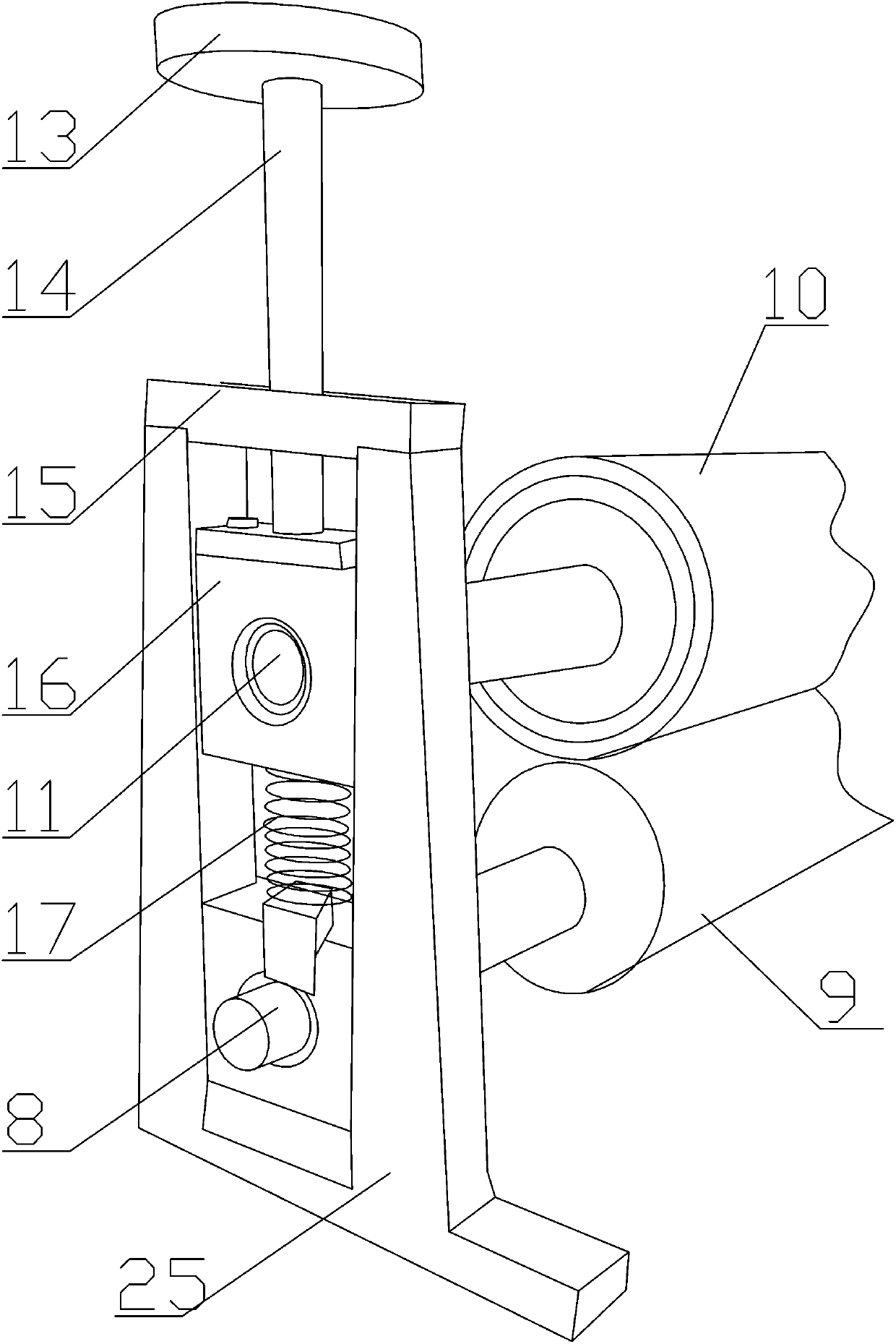

Abrasive paper printing and water feeding mechanism

InactiveCN110039896ASave spaceNormal water filling processOther printing apparatusPrinting press partsPulp and paper industryEmery paper

The invention provides an abrasive paper printing and water feeding mechanism. A first bottom transitional roller and a second bottom transitional roller are installed on the bottom layer of a machineframe. Vertical pillars are fixed to the machine frame, and a plurality of supporting cross beams are installed between the vertical pillars. Water grooves are installed in the supporting cross beamsin a supporting mode. A pedestal is fixedly installed at the tops of the vertical pillars. A water roller spindle is installed on the pedestal, and a water roller is installed on the water roller spindle. An extrusion roller spindle is installed at the upper end of the water roller spindle, and an extrusion roller is installed on the extrusion roller spindle. The extrusion roller spindle is installed on a slippage block in a supporting mode. The top of the slippage block and a threaded hole in the middle of a top plate are in threaded transmission fit through a vertical screw rod. A hand wheel is installed at the top of the vertical screw rod. A spring is installed between the slippage block and the water roller spindle. According to the installation and adjustment mechanism, the mode that the water grooves are used for fixing to adjust the height of the water roller is adopted to ensure contact between the water roller and water in each water groove.

Owner:湖北瑞泰德研磨科技有限公司

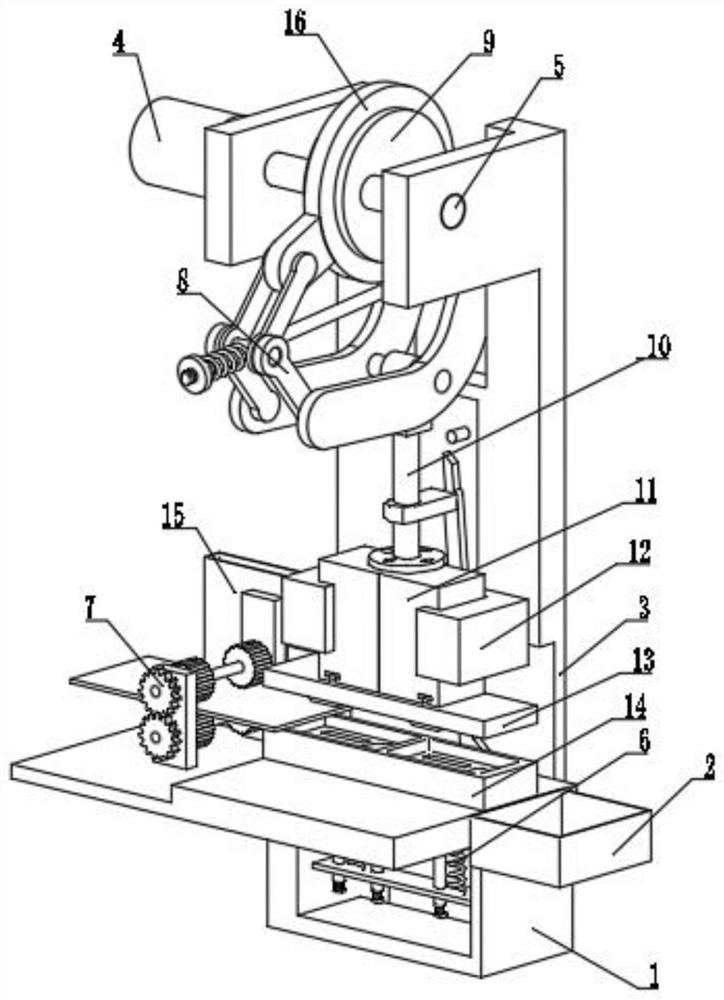

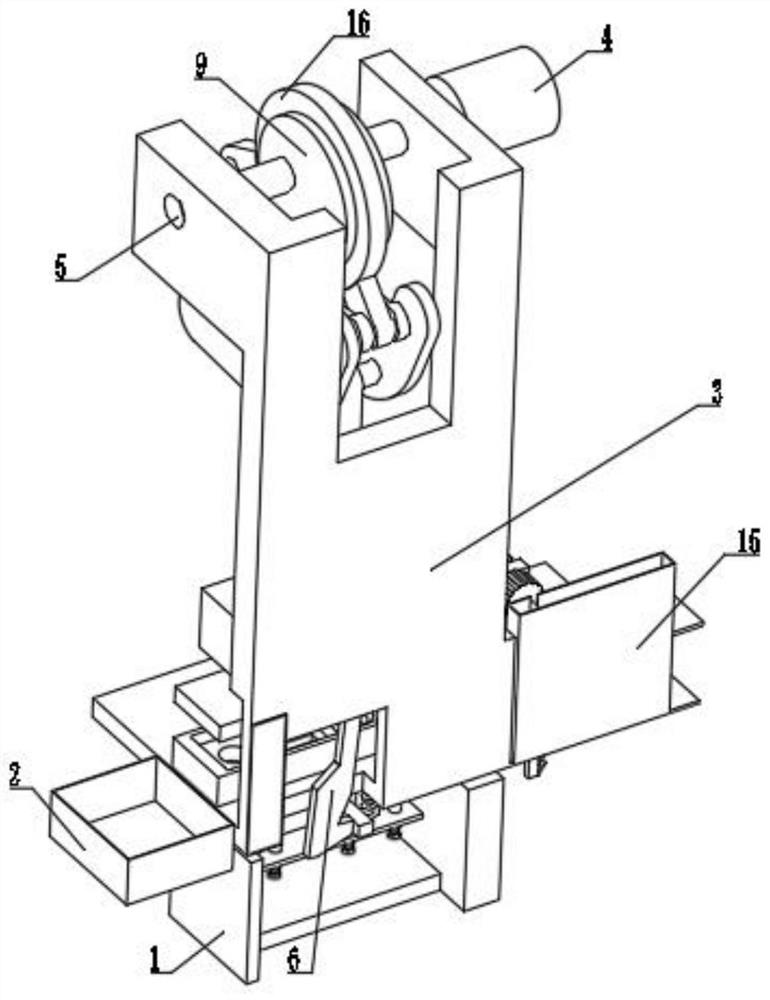

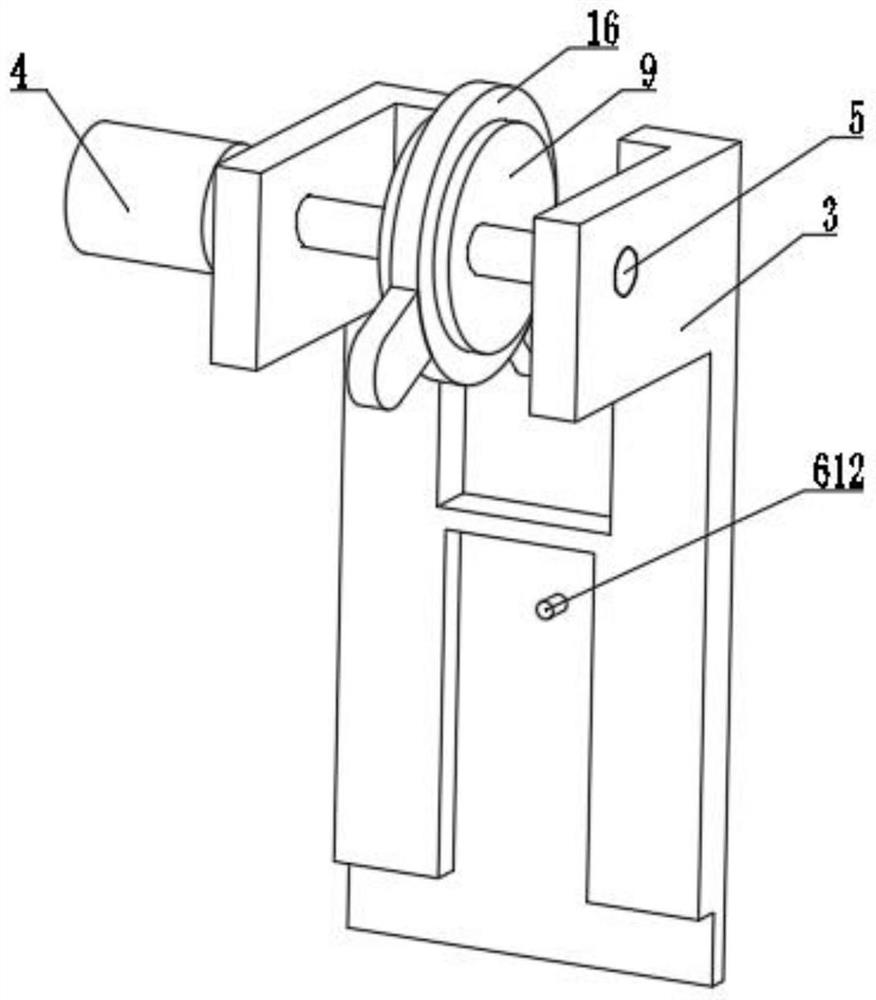

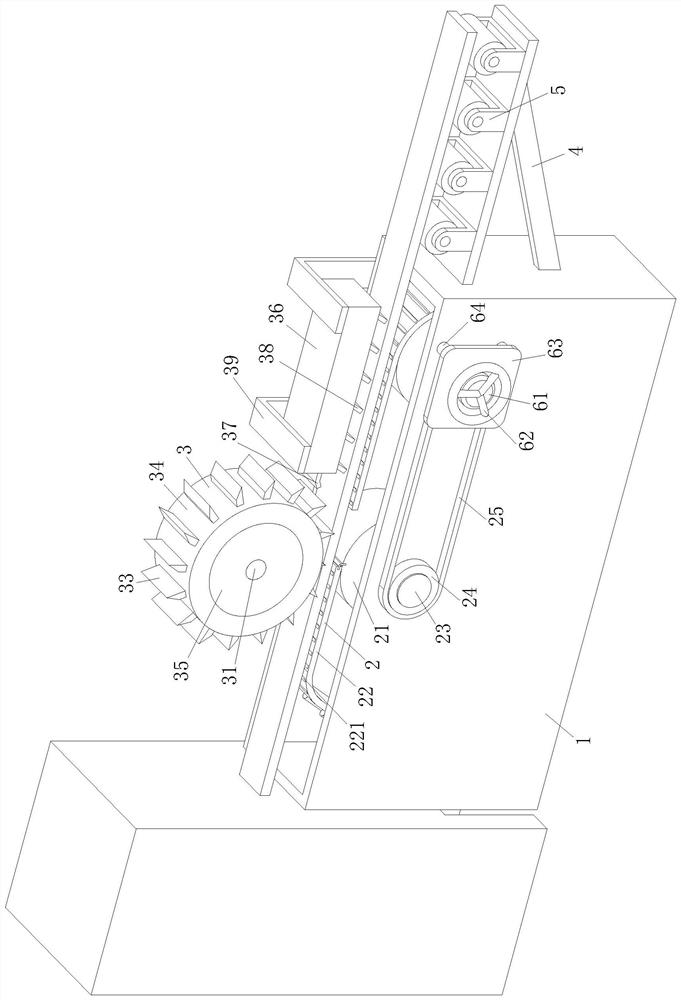

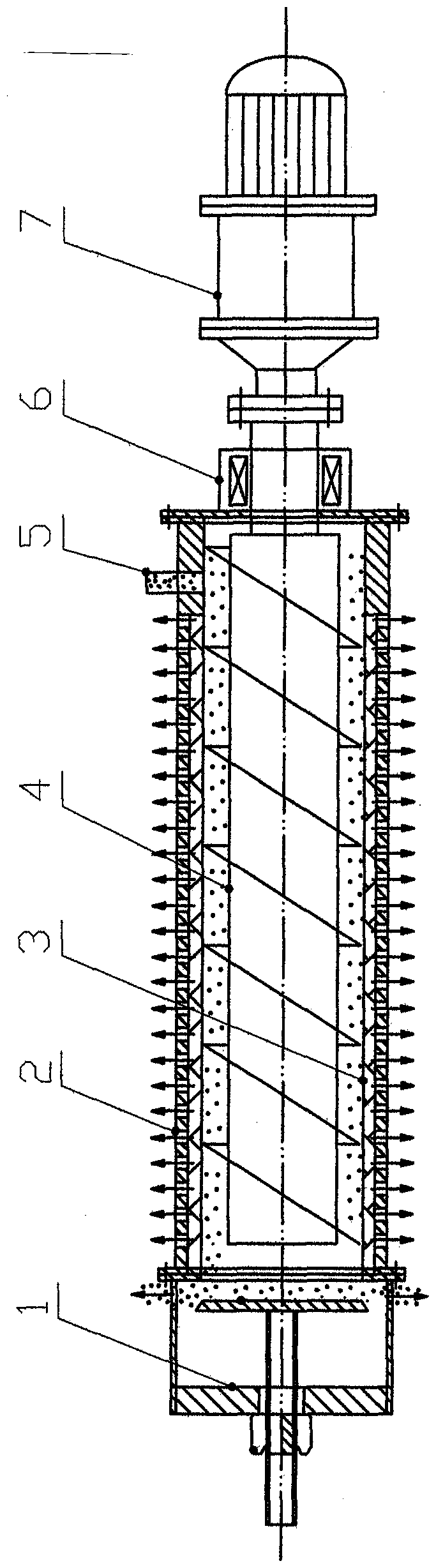

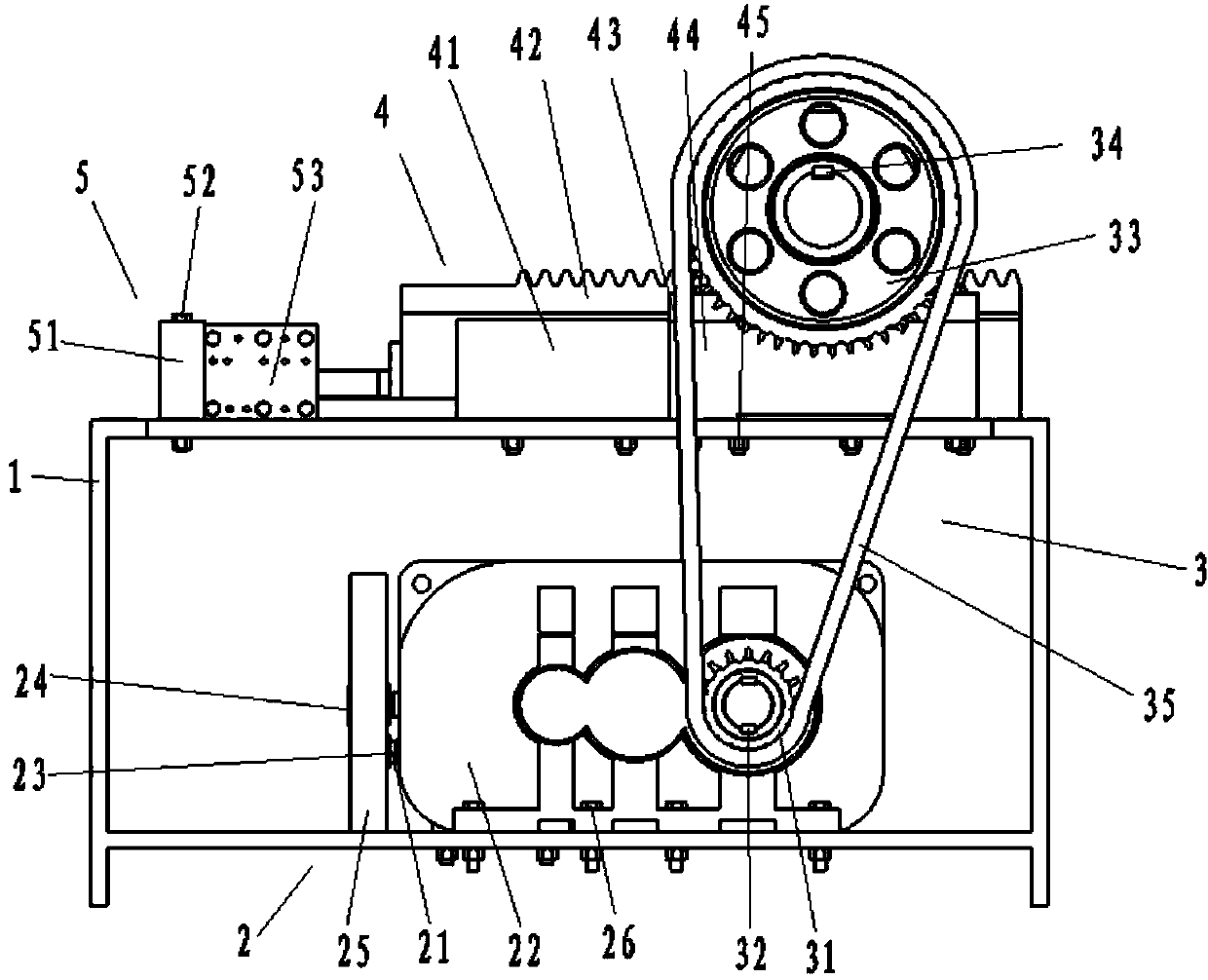

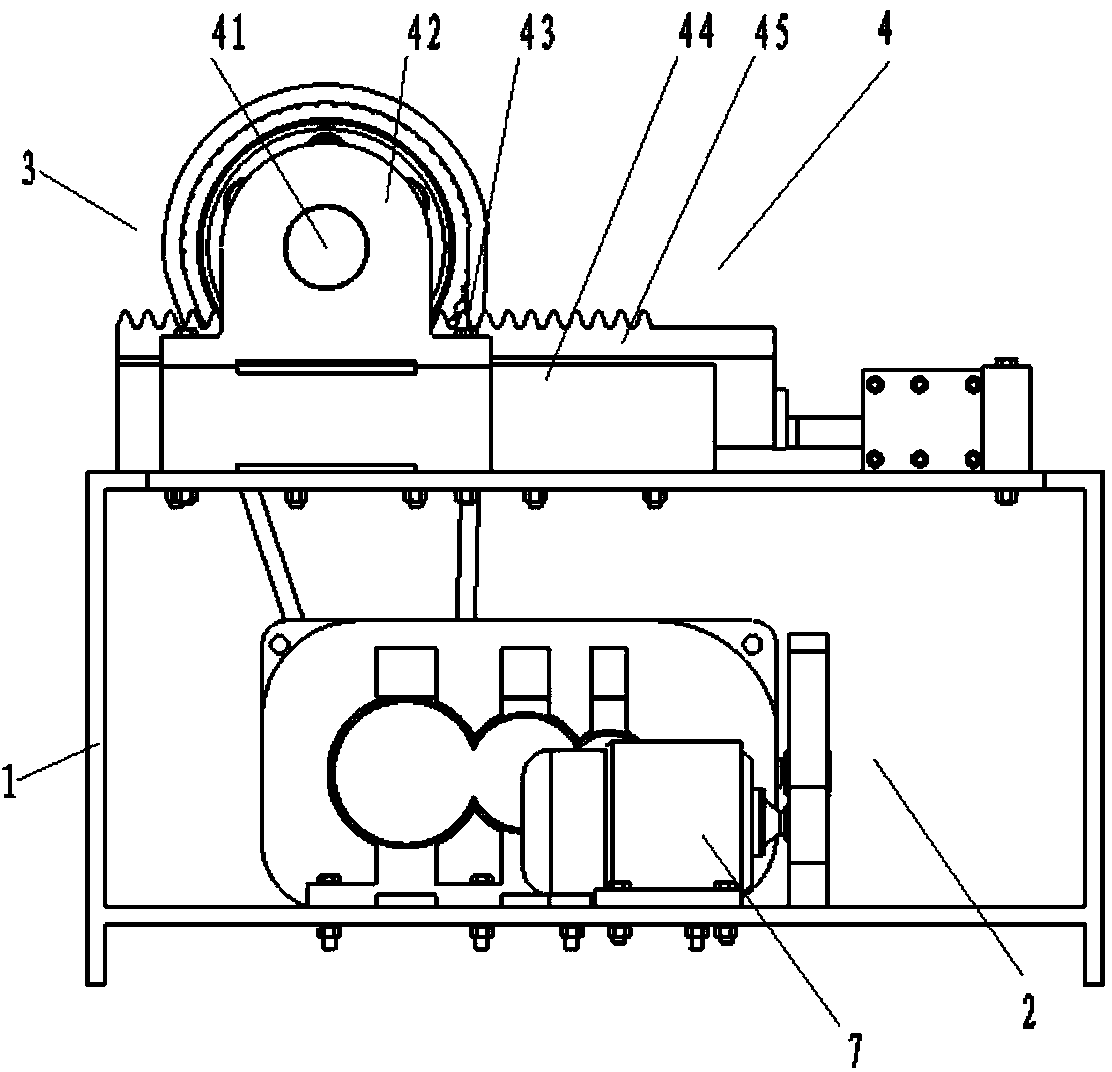

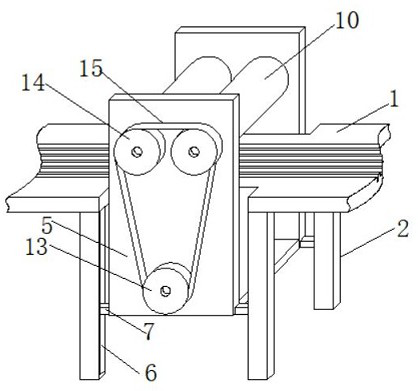

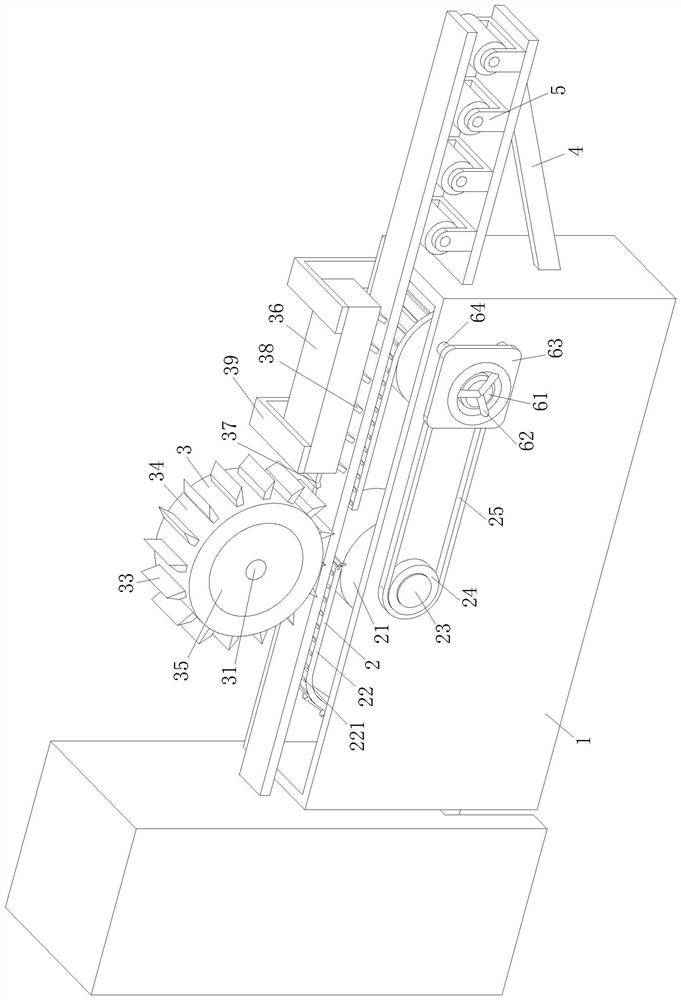

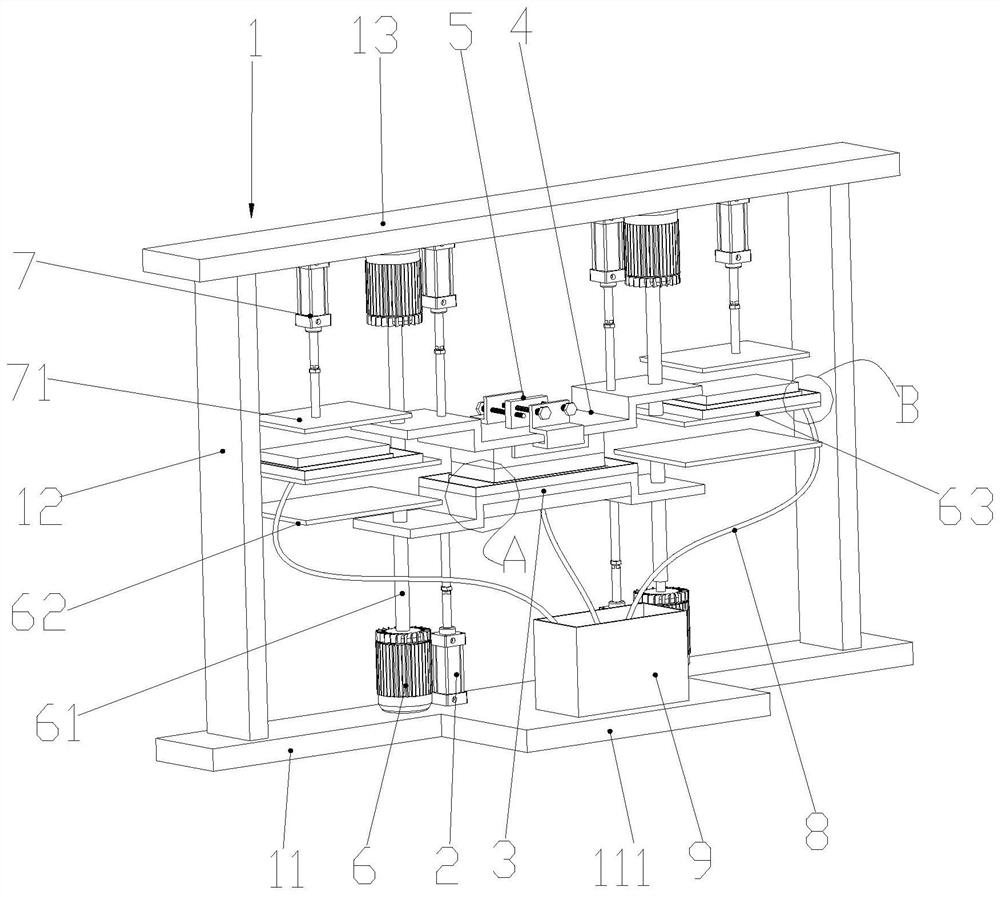

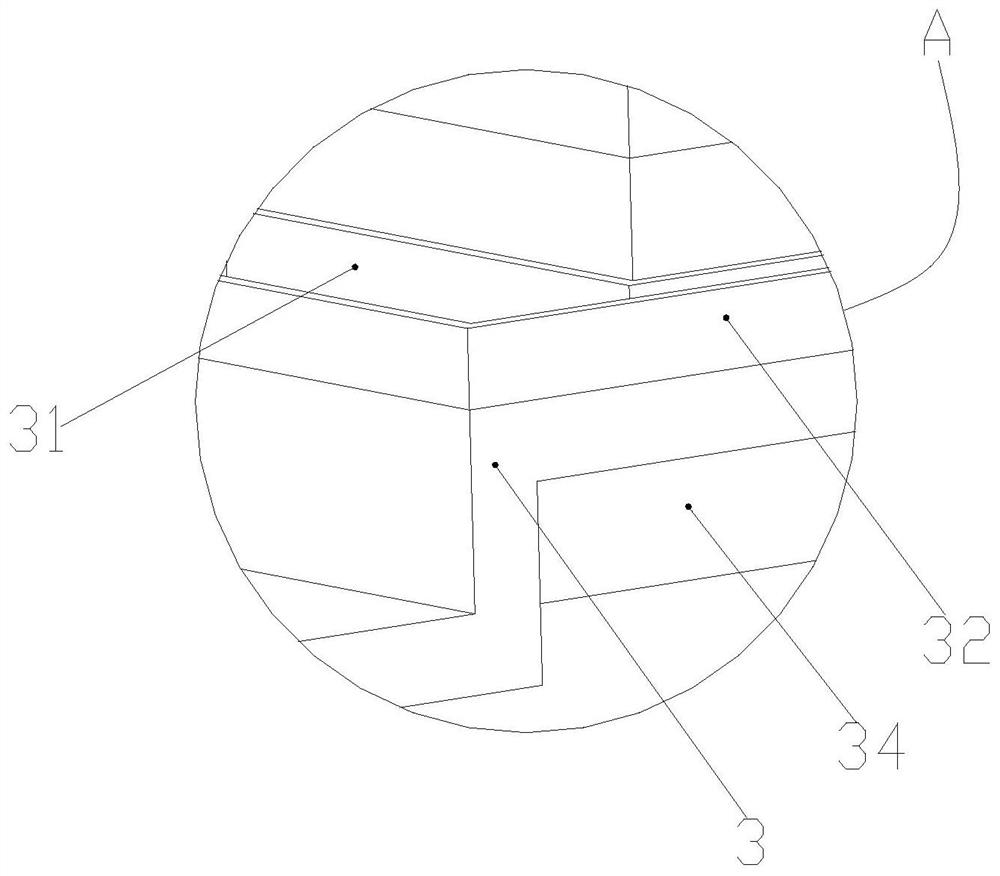

Device special for equal channel angular extrusion

The invention discloses a device special for equal channel angular extrusion. The device comprises a fixing support, a belt transmission mechanism, a chain transmission mechanism, a horizontal movement mechanism and a die fixing mechanism; the belt transmission mechanism is used for outputting and transmitting rotating power of a motor to an input shaft of a reducer, and the rotating power is output after speed reduction of the reducer; the chain transmission mechanism is used for transmitting the rotating motion output by the reducer to the horizontal movement mechanism; the horizontal movement mechanism is used for converting the rotation motion into low-speed horizontal movement; and the die fixing mechanism is used for fixing a die obtained after equal channel angular extrusion, and equal channel angular extrusion is completed through the die under horizontal movement of the horizontal movement mechanism. The device special for equal channel angular extrusion is specially developed according to the equal channel angular extrusion process, the high-speed rotation motion of the motor can be changed into low-speed horizontal movement, the output extrusion force magnitude and the extrusion speed can be adjusted at any time according to the equal channel angular extrusion process, and the device has the beneficial effects of being high in efficiency, simple in structure, good in reliability, safe in operation and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

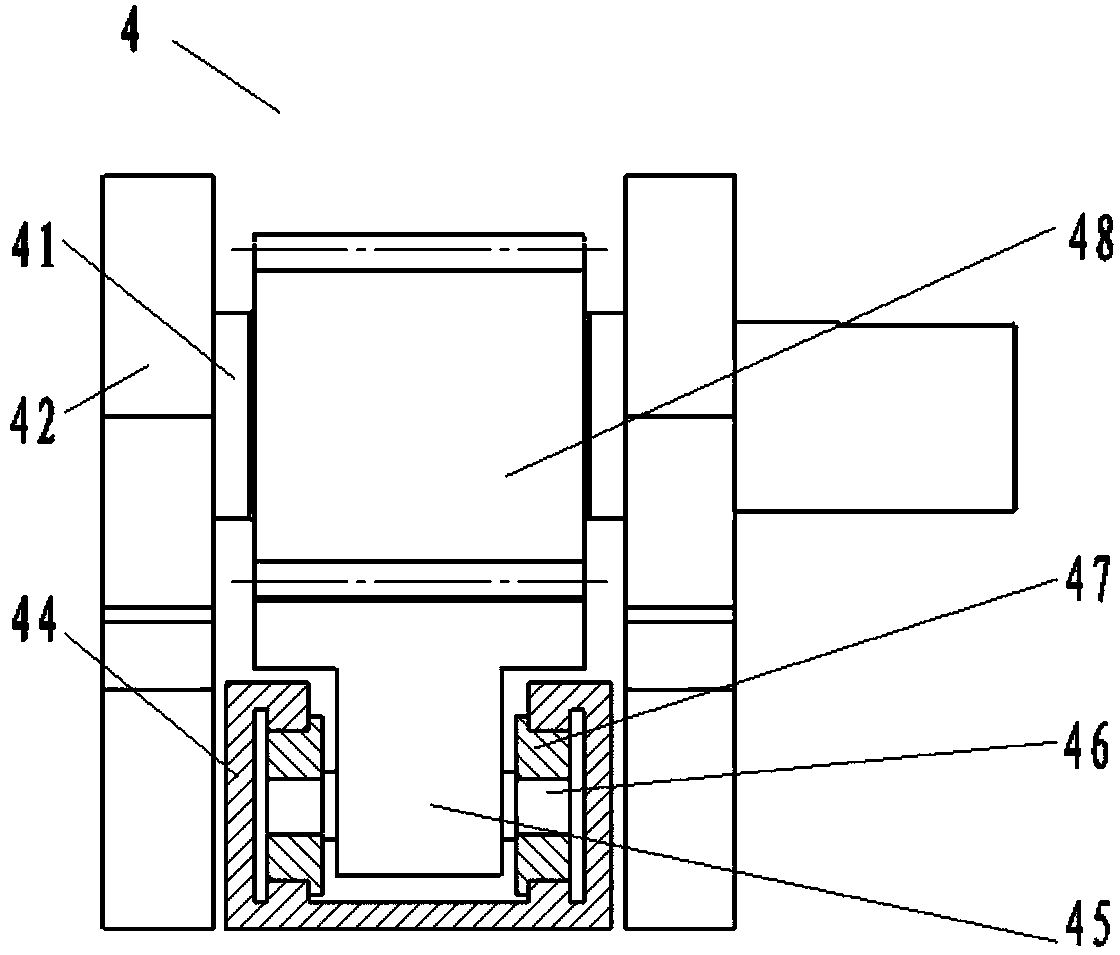

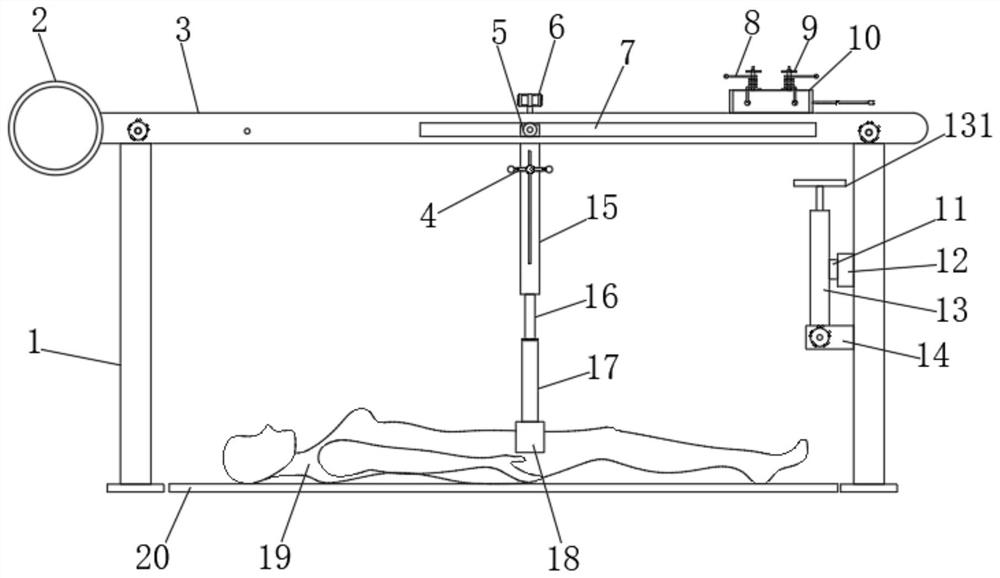

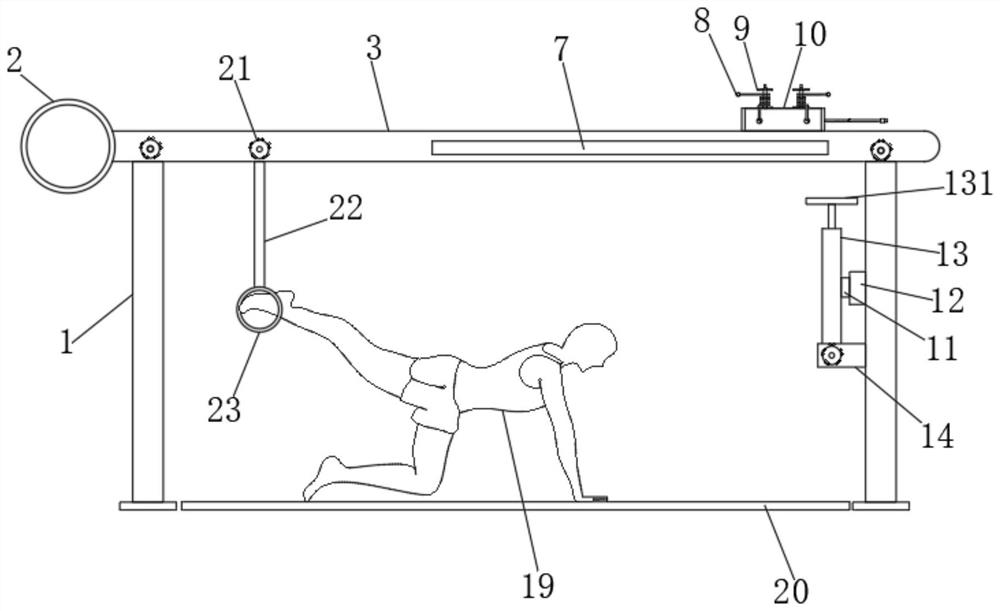

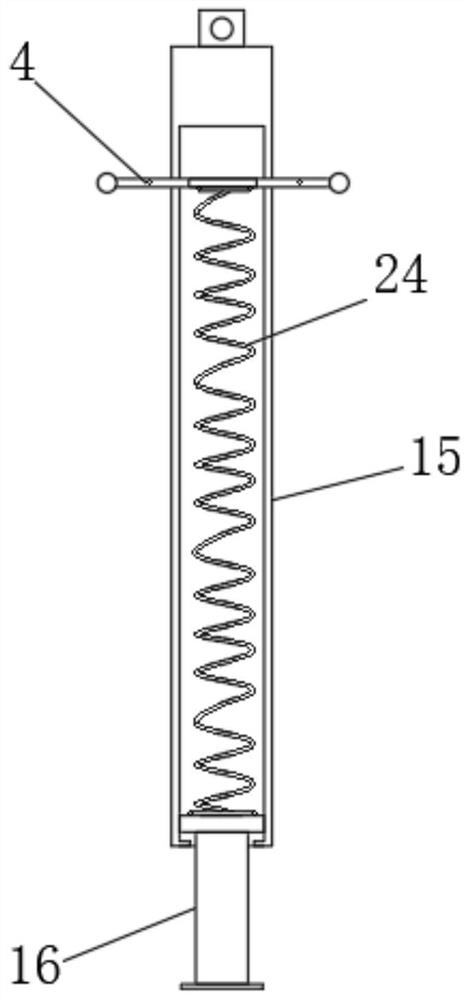

Pelvic floor muscle training equipment used after obstetric operation

InactiveCN111840934AAdjust extrusion forceMeet training needsGymnastic exercisingPhysical medicine and rehabilitationEngineering

The invention discloses pelvic floor muscle training equipment used after an obstetric operation. The invention relates to the technical field of pelvic floor muscle training. The equipment comprisesa mounting plate, and supporting columns are mounted at the four corners of the bottom of the mounting plate correspondingly. A sliding groove is formed in one side of the mounting plate; a sliding assembly is mounted in the sliding groove; a second cylinder is mounted at the bottom of the sliding assembly; a second spring is mounted in the second cylinder; a second piston rod is mounted at the bottom of the second cylinder; a connecting rod is mounted at the bottom of the second piston rod; and two sliding rails are symmetrically arranged on the outer wall of the second cylinder. According tothe pelvic floor muscle training equipment, the second cylinder is installed on the mounting plate, the training requirements of a user at different stages are met; in the training process, the usercan attach the electrotherapy patch to the pelvic floor muscle position, the pelvic floor muscle group is quickly awakened, training is conducted at the same time in cooperation with two methods of training actions, and the training quality is improved.

Owner:张瑞花

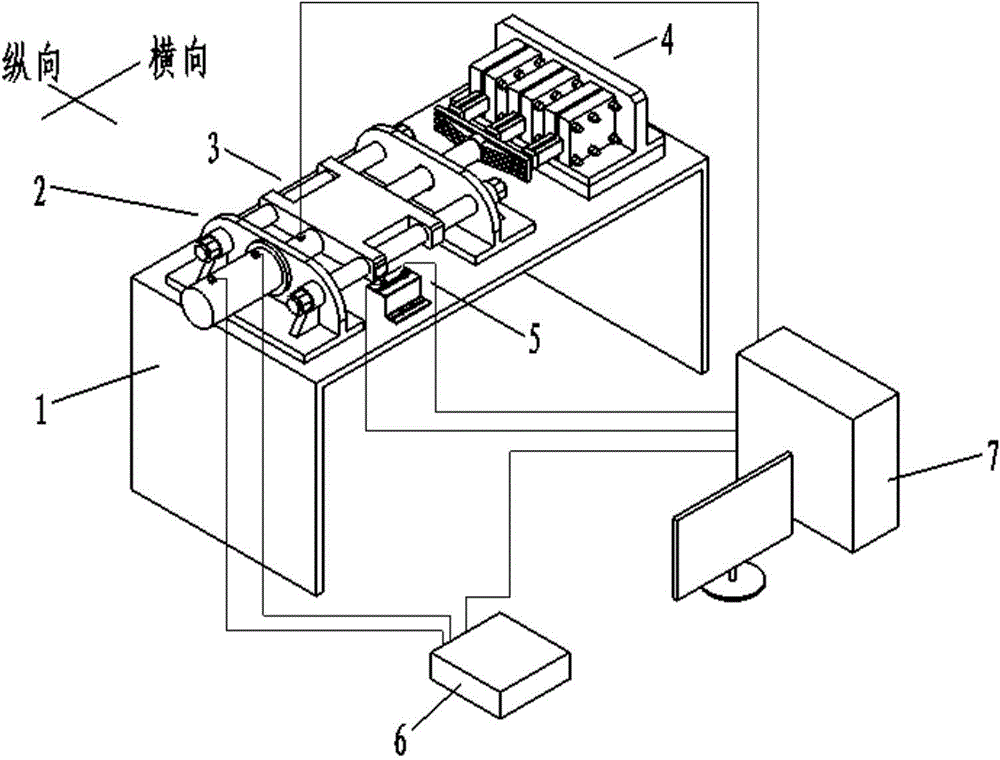

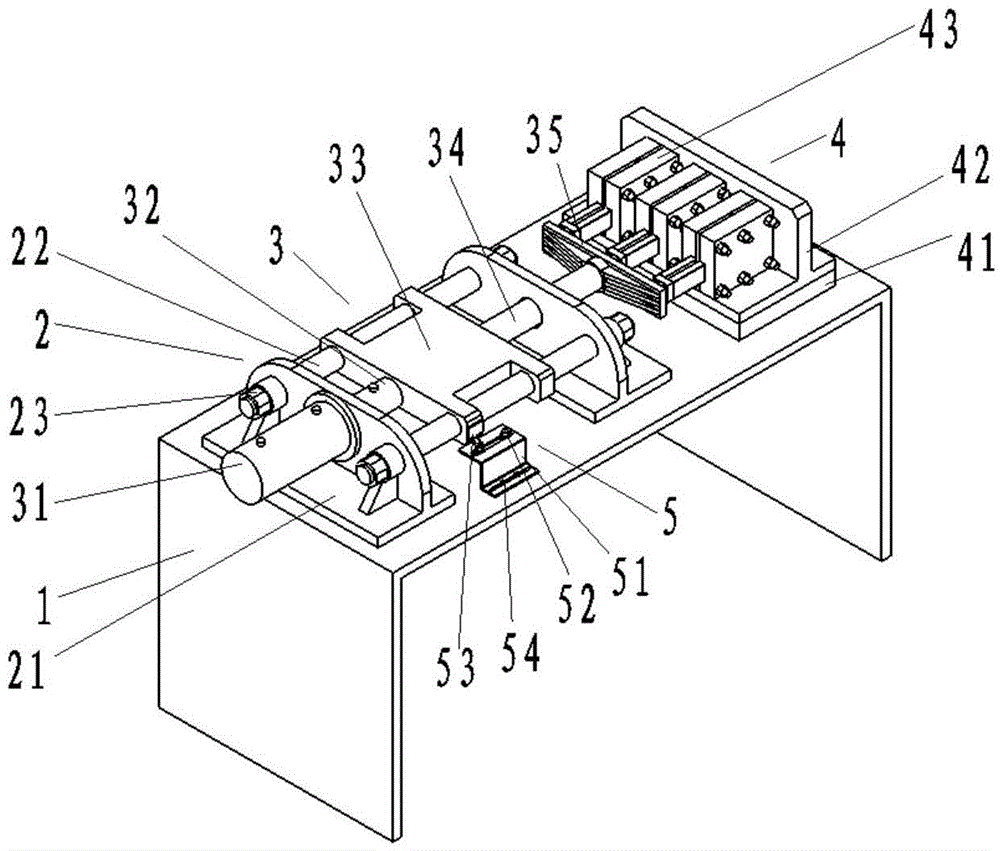

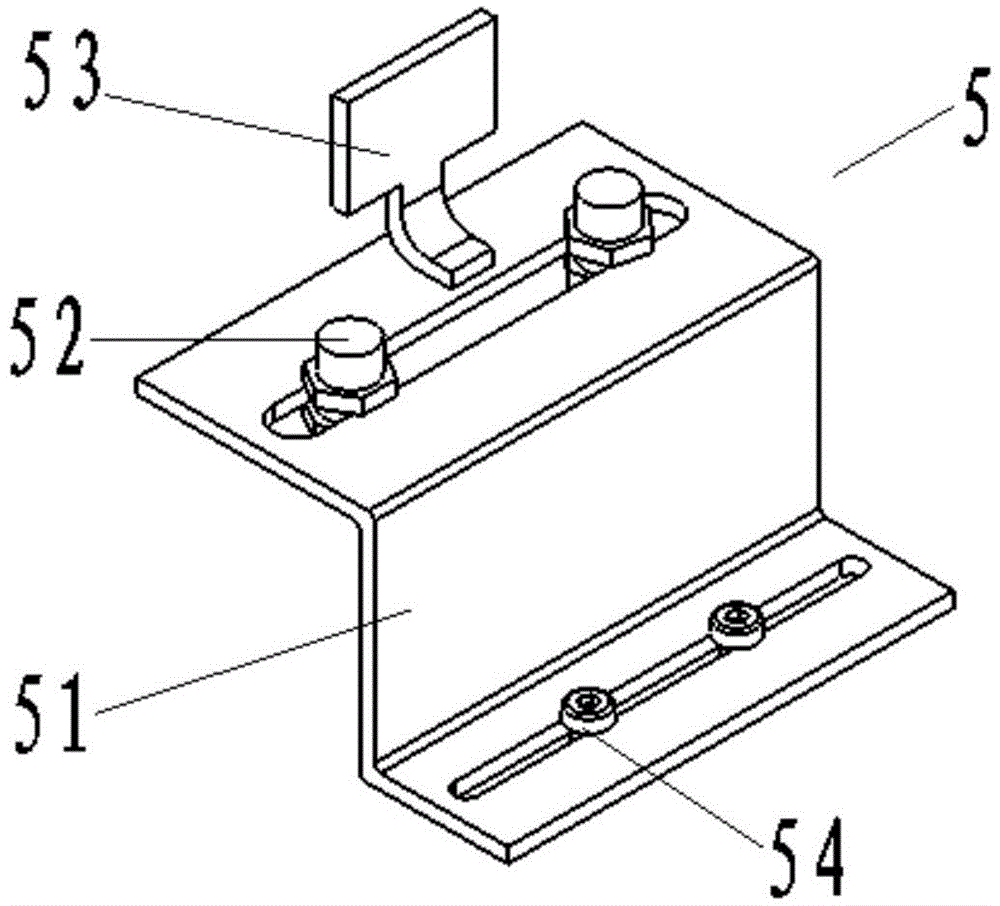

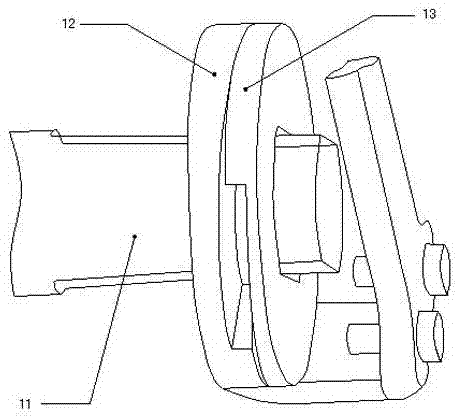

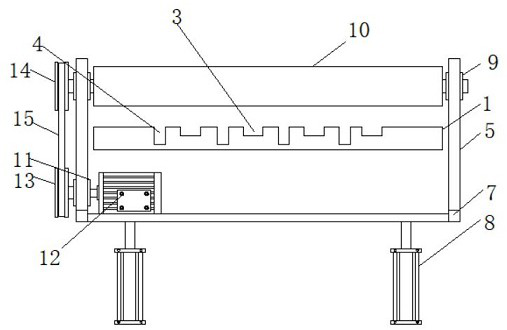

Hydraulic equal-channel corner extrusion device

ActiveCN105583246AImprove extrusion efficiencyUniform Extrusion ParametersExtrusion control devicesReciprocating motionFixed frame

The invention discloses a hydraulic equal-channel corner extrusion device which comprises a fixed frame, a guide rail mechanism, a pushing mechanism, a die fixing mechanism, a travel detection mechanism, a hydraulic control module and a computer, wherein the guide rail mechanism and the pushing mechanism are mounted on the fixed frame; the pushing mechanism is mounted on the guide rail mechanism and can do transverse reciprocating motion along the guide rail mechanism; the die fixing mechanism is used for fixing a die; the travel detection mechanism is used for detecting a travel of the pushing mechanism; the hydraulic control module can control the transverse moving speed and the extrusion force of the pushing mechanism; the computer is connected with the pushing mechanism, the travel detection mechanism and the hydraulic control module respectively and can be used for acquiring data of the travel of output force of the pushing mechanism and sending a control instruction to control the moving speed and the output extrusion force of the pushing mechanism. The hydraulic equal-channel corner extrusion device can adjust the output extrusion force and the speed and has the advantages of high efficiency, high reliability, safety in operation and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Adjustable locking mechanism

ActiveCN103307063BAdjustable positionAdjust extrusion forceFriction grip releasable fasteningsLocking mechanismEngineering

The invention relates to the technical field of locking mechanisms, in particular to an adjustable locking mechanism. The adjustable locking mechanism is adjustable in locking force and further comprises a locking screw, a spring and a check ring; a movable locking block, a fixed locking block, the spring and the check ring are embedded on a connecting shaft in sequence; one end of the spring is connected with the fixed locking block, and the other end of the spring is connected with the check ring; the locking screw is installed on the connecting shaft and connected with the check ring. The adjustable locking mechanism can be widely used for fastening or fixing elements.

Owner:JIANGXI HONGDU AVIATION IND GRP

A kind of active embossing equipment for low melting point film

ActiveCN111251593BIncrease coefficient of frictionImprove skid resistanceFrictional coefficientElectric machinery

Owner:仲铂新材料有限公司

A backlight aluminum substrate pasting adhesive process

ActiveCN113260107BReduce crushing and crushingPress firmlyElectrical apparatusElectroluminescent light sourcesAdhesiveEngineering

The invention discloses a process for attaching back glue to an aluminum substrate of a backlight source, which includes a workbench, a plurality of support columns are fixedly connected to the bottom end of the workbench, and a plurality of LED air-avoiding grooves are opened on the top of the workbench, and the workbench A plurality of socket avoidance slots are provided on the top of the table, and a C-shaped bracket is socketed and connected to the surface of the middle end of the work table. In the present invention, the servo motor can drive the two pressing wheels to rotate in the same direction, so that it can squeeze the top of the substrate, and squeeze and bond the substrate and the adhesive on the surface to make it press together. It is more stable, changing the previous method of double-sided extrusion of the substrate to prevent double-sided extrusion and reduce the situation of LED lamp beads being squeezed and broken. The protruding LED lamp beads and socket terminals on the substrate can be socketed in the empty slot, so that when the pressing wheel is glued, it can prevent the protruding lamp beads and terminals from pressing the surface of the workbench and causing damage.

Owner:惠州市炬能量电子科技有限公司

Method for recycling environment-friendly semiconductor chip wafer with reusable mucilage glue

InactiveCN114311347AConvenient recycling workAchieve the purpose of conveying and cuttingSemiconductor/solid-state device manufacturingWorking accessoriesAdhesive beltBiochemical engineering

The invention discloses a recycling method for an environment-friendly semiconductor chip wafer with reusable adhesive. The recycling method specifically comprises the following steps that S1, a semiconductor chip to be recycled is conveyed to a recycling device through feeding conveying equipment; and S2, starting the recovery processing device to sequentially carry out adhesion, cutting and scraping recovery processing. The invention relates to the technical field of semiconductor chip production. According to the recycling method for the environment-friendly semiconductor chip wafer with the reusable adhesive, the adhesive tape can be replaced by the reusable adhesive mechanism for repeated recycling, the purpose of conveying and cutting the chip wafer in a practical and environment-friendly mode is well achieved, the production cost is greatly reduced, and the production efficiency is improved. The device is simple in structure and convenient to operate, waste of a large amount of adhesive tape is avoided, serious pollution of the adhesive tape to the environment is prevented, meanwhile, cutting, discharging and adhesive removing can be combined, integrated semiconductor chip recycling is carried out, and the labor intensity of workers is greatly reduced.

Owner:张雪茹

Anti-deformation aluminum profile conveying device

ActiveCN111717611AImprove surface qualityWon't hurtLoading/unloadingConveyor partsSprocketChain link

The invention belongs to the technical field of conveying devices, and particularly relates to an anti-deformation aluminum profile conveying device. The anti-deformation aluminum profile conveying device comprises a supporting box, a lower supporting component, a cooling component, an inclined support and a driven roller; and the lower supporting component comprises a winding wheel, an elastic metal belt, a supporting rotating shaft, a chain wheel, a chain, a guide rod and friction wheels. According to the anti-deformation aluminum profile conveying device, the elastic metal belt provided with an free end is uniformly attached to the lower surface of the just-formed aluminum profile, so that the supporting area of the just-formed aluminum profile is increased, the just-formed aluminum profile is prevented from deforming due to low strength, the quality of the just-formed aluminum profile in the conveying process is improved, and the manufacturing precision of the aluminum profile is further improved; and when the free end of the elastic metal belt falls into cooling liquid in the supporting box body, the elastic metal belt is cooled, it is guaranteed that the elastic metal belt has stable elasticity, the supporting effect of the elastic metal belt is guaranteed, and then the manufacturing quality of the aluminum profile is improved.

Owner:佛山市金浩联铝业有限公司

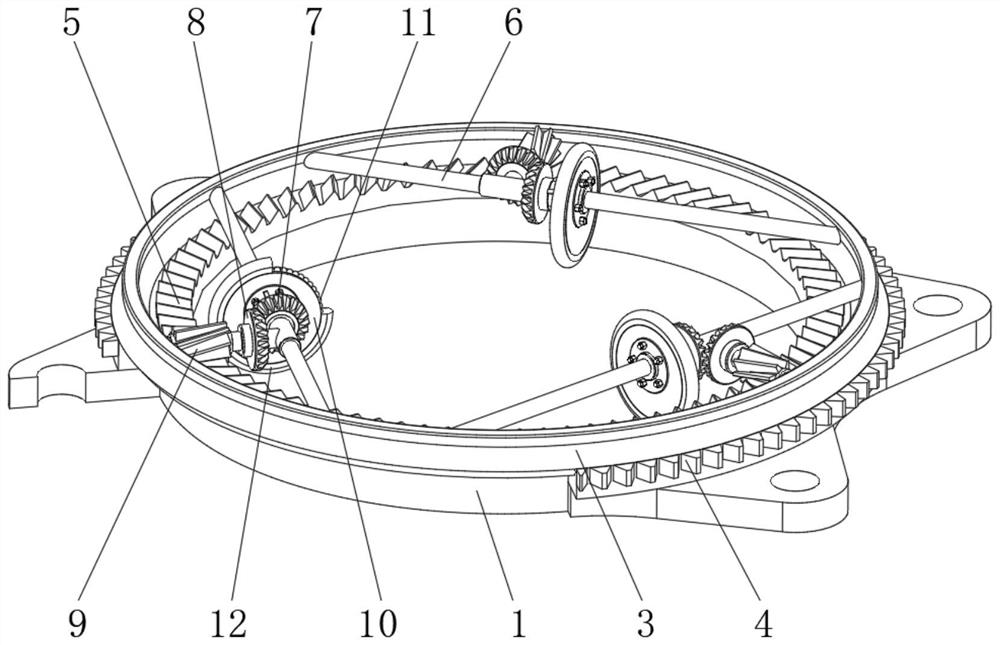

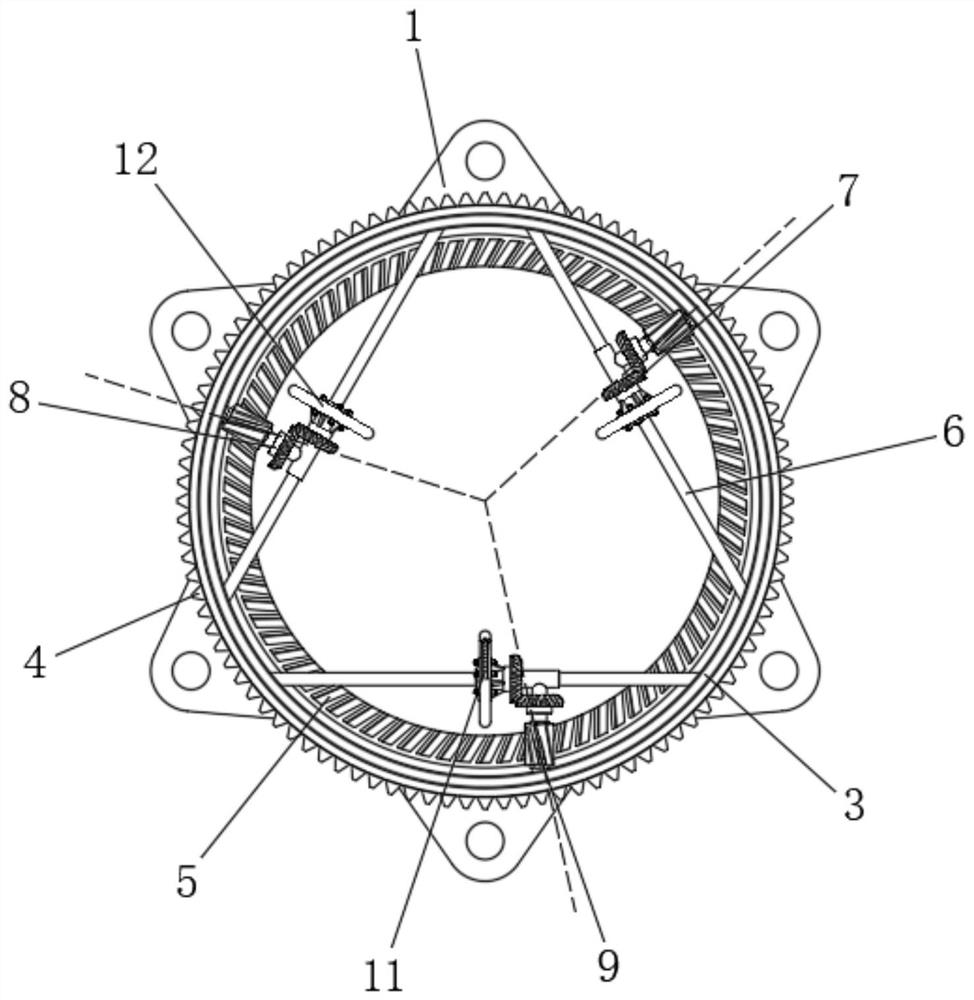

Adjustable embracing column guider based on steel casing positioning

InactiveCN113047287AAvoid the influence of positioning accuracyOptimize the control systemBulkheads/pilesGear wheelBevel gear

The invention relates to the technical field of pile foundation construction equipment, and discloses an adjustable embracing column guider based on steel casing positioning. The adjustable embracing column guider comprises a base, the top end of the base is movably sleeved with a driving ring, the top end of the driving ring is movably sleeved with a fixed clamping ring, the outer surface of the driving ring is provided with a transmission gear block, a helical tooth block is arranged at the top end of the driving ring and located in an inner cavity of the fixed clamping ring, and three fixed connecting rods are evenly arranged at the top of the inner cavity of the fixed clamping ring. According to the adjustable embracing column guider based on steel casing positioning, eccentric structures are arranged between bevel gears I and positioning discs, so that the effective rotating radii of the peripheries of guide sliding rings are conveniently changed in the rotating process of the positioning discs, and the size of the inner diameter of a circle center track among the vertexes of the three guide sliding rings is thus adjusted so as to be suitable for steel casings of different occasion specifications; and meanwhile, the extrusion force of the guider on the steel casings can be flexibly adjusted according to the actual construction environment, and the application range of the guider is greatly widened.

Owner:储心波

Blown film machine tube film water removal device

ActiveCN109571922BIncrease frictionAdjust extrusion forceCoatingsMembrane surfaceStructural engineering

The invention discloses a tube film dewatering device of a film blowing machine. The tube film dewatering device comprises a supporting frame, the supporting frame comprises a lower supporting plate,a supporting column and an upper supporting plate, the lower supporting plate and the upper supporting plate are fastened and connected through the supporting column, and first telescopic cylinders symmetrically distributed are arranged at the upper end of the lower supporting plate and the lower end of the upper supporting plate; and the top ends of the telescopic rods of the two first telescopiccylinders located at the upper end of the lower supporting plate and the lower end of the upper supporting plate are fastened and connected with a first supporting block and a second supporting block, a first limiting ring is arranged at the upper end of the first supporting block, and a clamping unit is arranged at the upper end of the second supporting block. A tube film device needing to suckthe surface water is placed between sponge in a clamping block and sponge clamped in the first limiting ring, the first telescopic cylinder is adjusted, the sponge is attached to the tube film surface, and water sucking is conducted on the tube film.

Owner:HEFEI XINDA MEMBRANE TECH

Agricultural water-saving drop irrigation head

InactiveCN105557465ASimple structureAdjust extrusion forceWatering devicesCultivating equipmentsWater savingRubber material

The invention relates to an agricultural water-saving drop irrigation head which comprises a cylindrical shell, an upper pressing pipe and a lower pressing pipe. The upper pressing pipe and the lower pressing pipe are installed in the shell. The agricultural water-saving drop irrigation head is further provided with a spring cap arranged between the upper pressing pipe and the lower pressing pipe in a squeezed mode. The spring cap is made of rubber materials. The upper pressing pipe is connected with a water source. The lower tail end of the upper pressing pipe and the upper tail end of the lower pressing pipe are provided with metal pressing tables respectively. The pressing tables are provided with inward concave faces. The pressing tables press the spring cap to the middle. The upper end and the lower end of the spring cap abut against nearby ports of the upper pressing pipe and the lower pressing pipe. The agricultural water-saving drop irrigation head is simple in structure and capable of adjusting seepage flow.

Owner:郭艳明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com