Tension adjustment device for copper wire unwinding rack

A tension adjustment, copper wire technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc. problems, to achieve uniform pay-off or rewind, increase stability, and evenly retract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

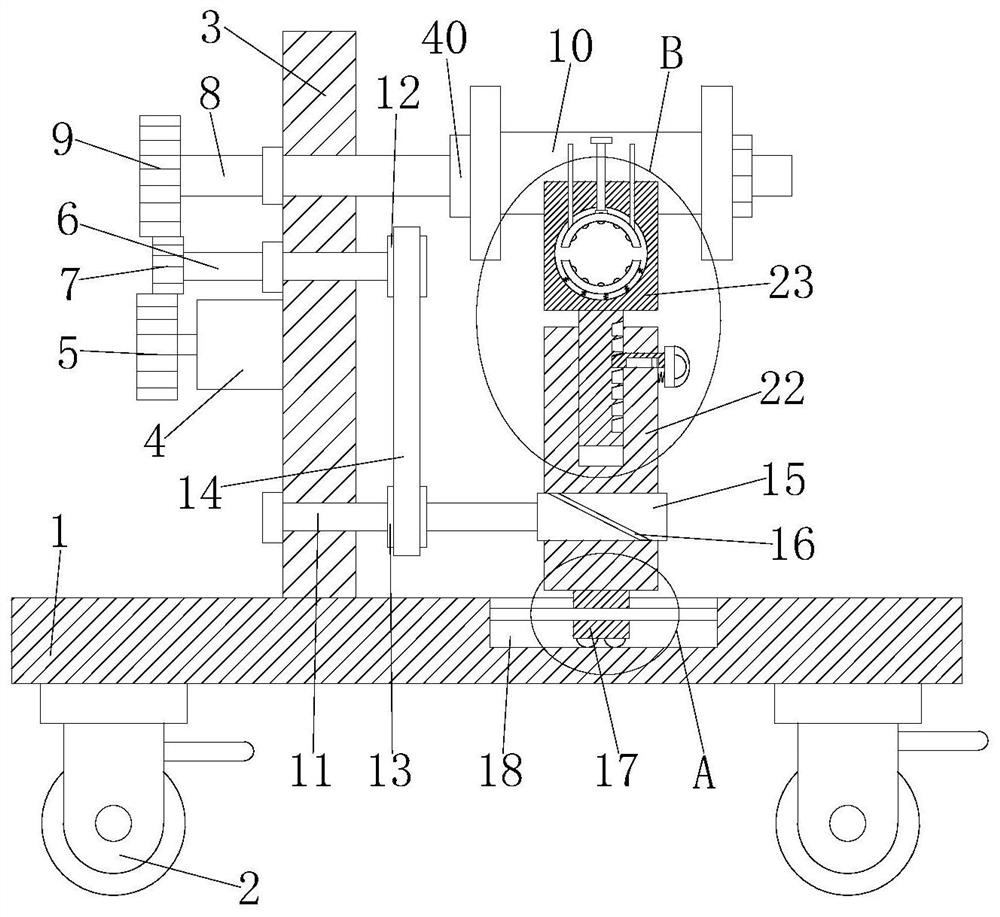

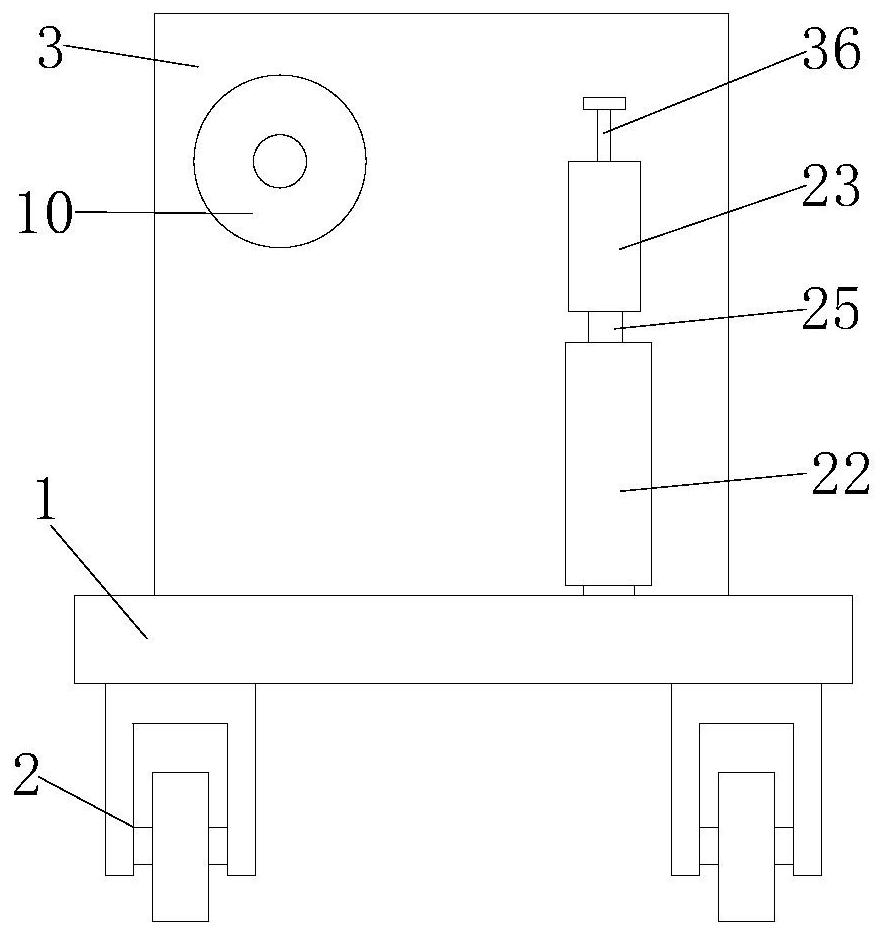

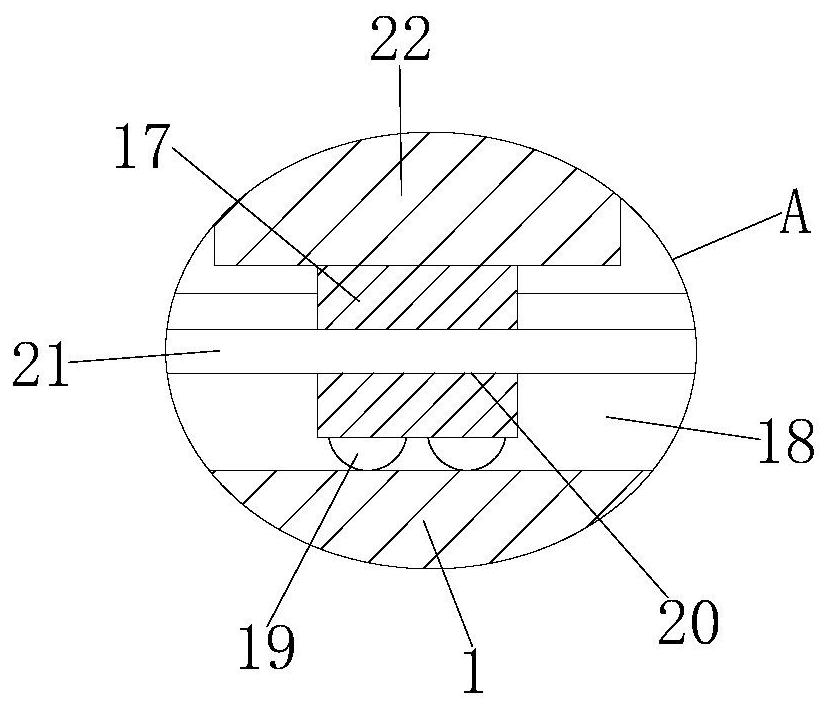

[0030] refer to Figure 1-5 , a tension adjustment device for a copper wire pay-off rack, comprising a base plate 1, four universal wheels 2 are fixedly connected to the bottom of the base plate 1, a vertical plate 3 is fixedly connected to the top of the base plate 1, and one side of the vertical plate 3 is fixedly connected There is a driving structure, and a transmission shaft 6 and a winding shaft 8 are installed for horizontal rotation on the vertical plate 3. The transmission shaft 6 is compatible with the driving structure, and the winding shaft 8 is compatible with the transmission shaft 6. Rewinding roller 10, the outer side of rewinding shaft 8 is provided with helical thread, and the outer side of helical thread is connected with nut, and nut can limit and fix rewinding roller 10, and the outer fixed sleeve of rewinding shaft 8 is provided with blocking sleeve 40, and the outer side of rewinding shaft 8 is provided with blocking sleeve 40. The roller 10 is in contac...

Embodiment 2

[0041] refer to Figure 1-5 , a tension adjustment device for a copper wire pay-off frame, comprising a base plate 1, the bottom of the base plate 1 is fixedly connected with four universal wheels 2 by screws, the universal wheels 2 can be conveniently moved, and the universal wheels 2 are provided with The brake pads can fix the universal wheel 2, the top of the bottom plate 1 is fixedly connected with a vertical plate 3 by screws, one side of the vertical plate 3 is fixedly connected with a drive structure, and the vertical plate 3 is horizontally rotated and installed with a drive shaft 6 and Rewinding shaft 8, transmission shaft 6 is compatible with drive structure, and winding shaft 8 is compatible with transmission shaft 6, and the outer fixed sleeve of winding shaft 8 is provided with winding roller 10, and the outer side of winding shaft 8 is provided with helical pattern, and spiral There is a nut threaded on the outer side of the pattern, the nut can limit and fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com