Ash processing production line and processing method

A production line and ash powder technology, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of secondary pollution in the workshop working environment, secondary dust pollution in the environment, poor water absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

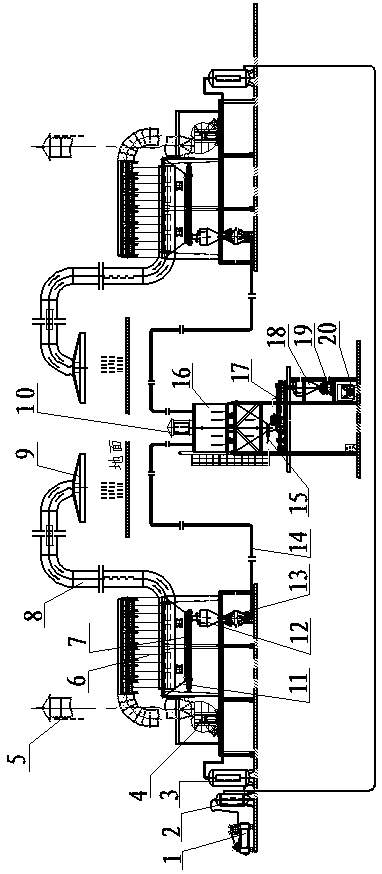

[0035] refer to Figure 1-Figure 11 , the soot processing production line of the present embodiment, it comprises ash powder collecting system, ash powder feeding system, ash powder pressure feeding system, stirring system and ball making system, described ash powder collecting system, ash powder feeding system, ash powder There are two sets of pressure feeding systems, the ash powder collection system and the ash powder feeding system are connected through pipelines, the pipeline interface is provided with a sealing gasket, and the ash powder pressure feeding system is connected to the ash powder feeding system in turn And the mixing system, the mixing system is connected with the ball making system, the whole production line is carried out in a fully closed state, avoiding dust, and completely solving the technical problem of dust pollution caused by ash powder to the environment.

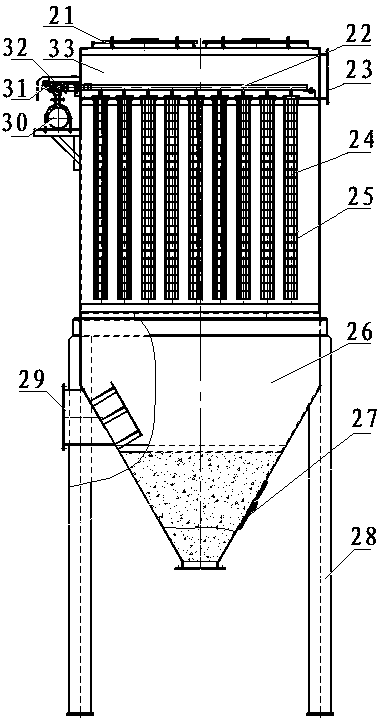

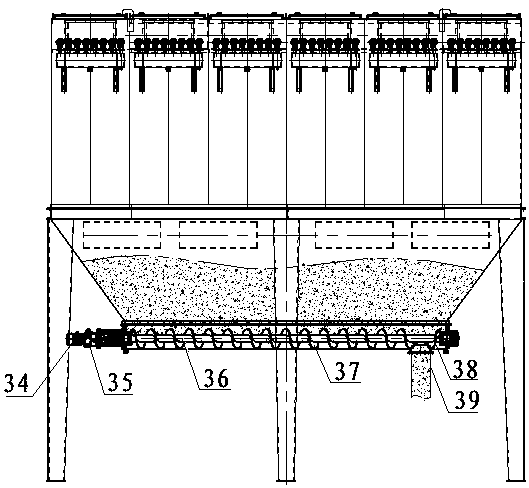

[0036] The dust collection system includes a dust collection hood 9, a dust suction pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com