Tool holder

A technology for tools and machining parts, which is applied to honing tools, manufacturing tools, metal processing equipment, etc., and can solve problems such as changing the grinding diameter and changing the surface pressure of the grinding stone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Exemplary embodiments according to the present invention are described below with reference to the accompanying drawings.

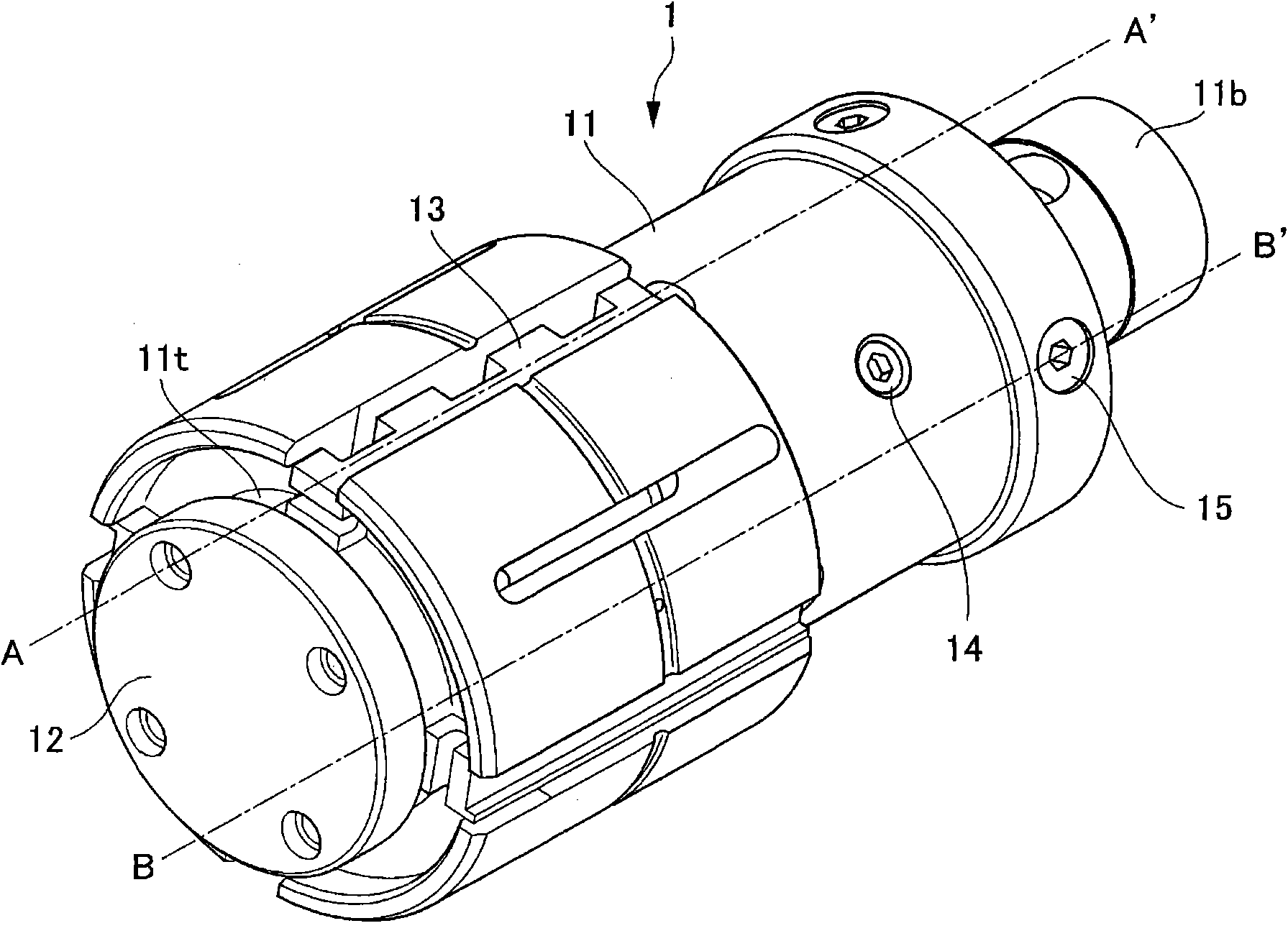

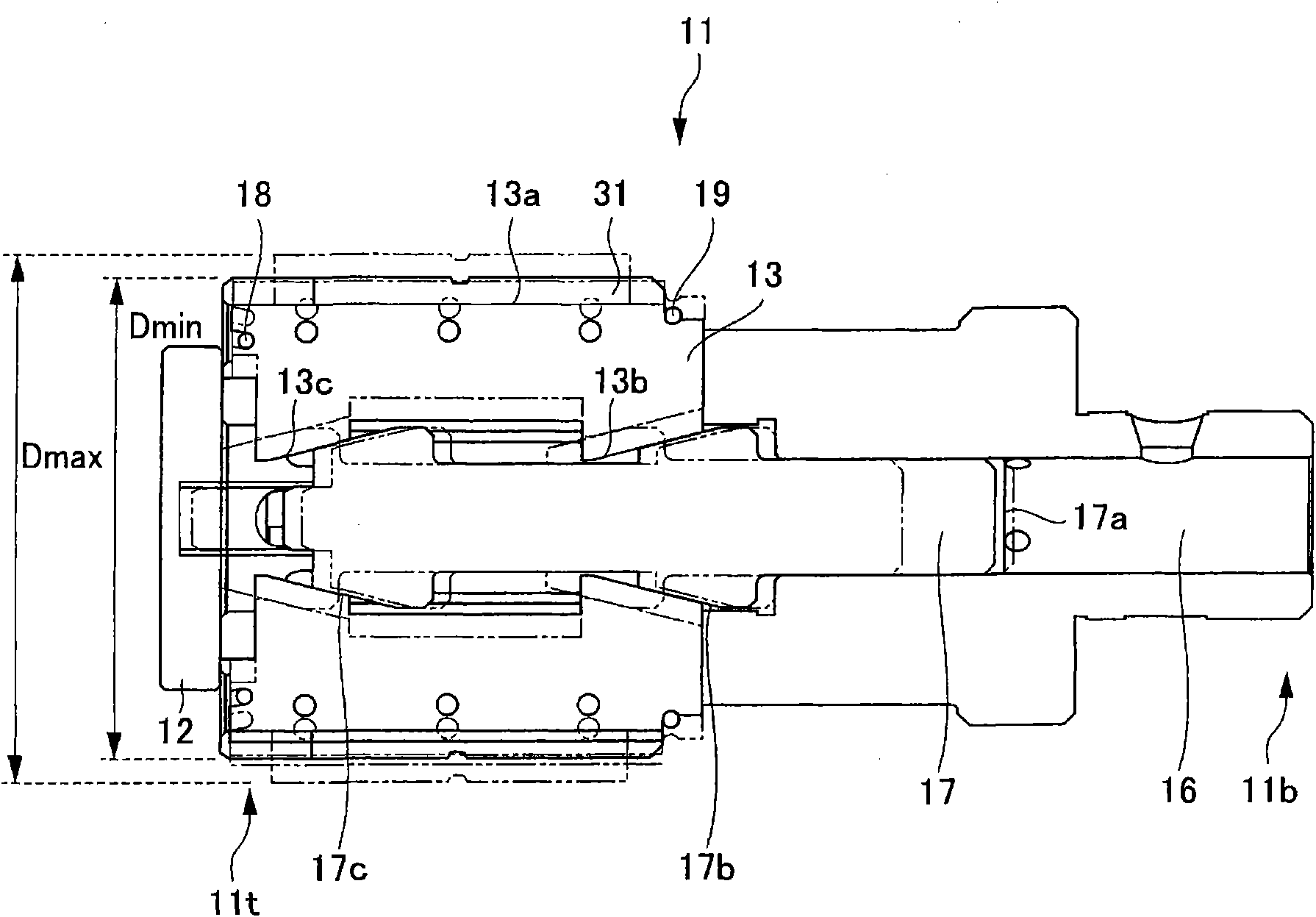

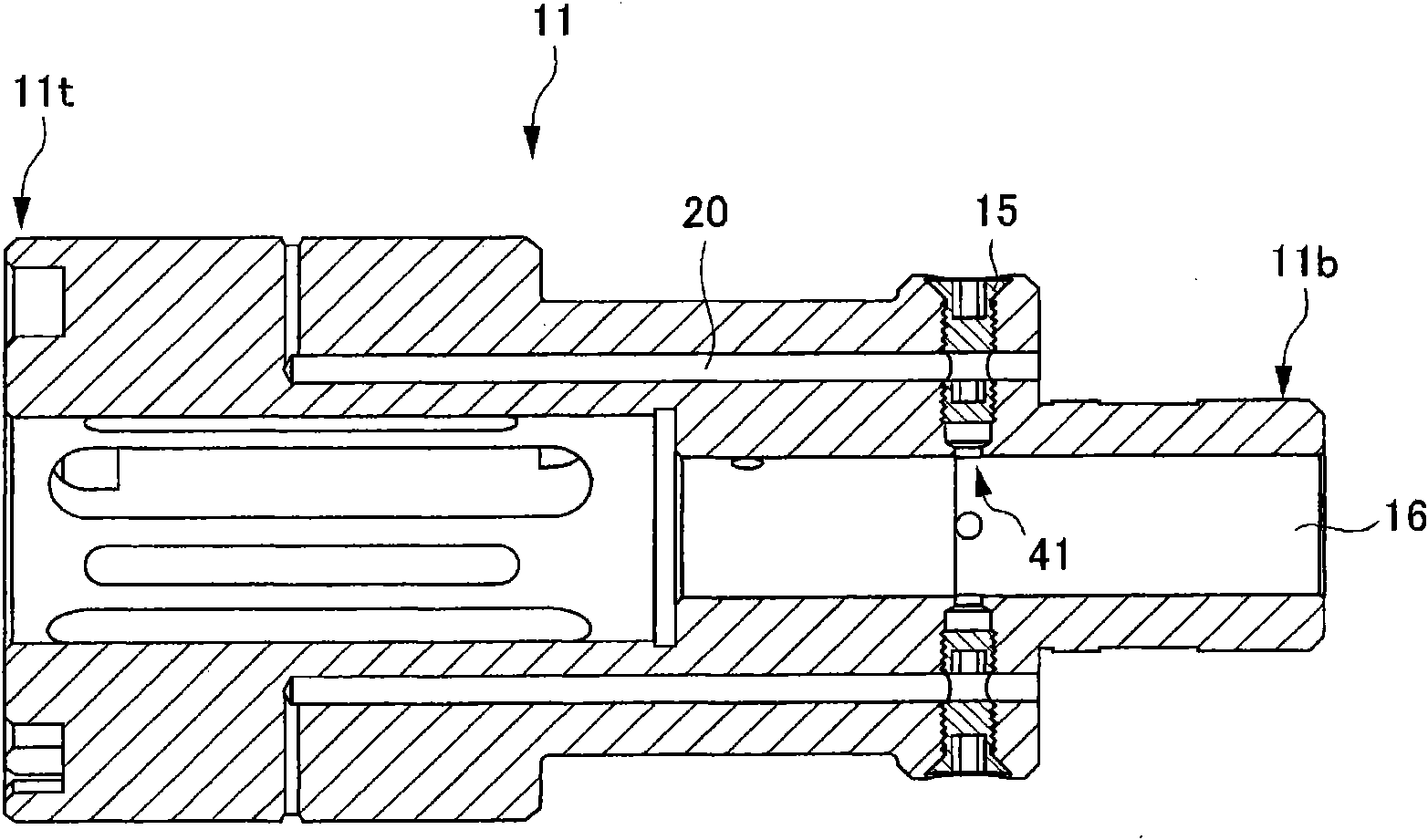

[0024] figure 1 is a perspective view of a schematic structure of a honing stand 1 according to an exemplary embodiment of the present invention. figure 2 for the honing bracket 1 along the figure 1 A cross-sectional view taken along line A-A'. image 3 for the honing bracket 1 along the figure 1 Sectional view taken along line B-B'.

[0025] like Figure 1 to Figure 3As shown, a honing stand 1 for use in honing operations includes a main body 11, an end cap 12, a grinding shoe 13, a set screw 14, a screw adjuster 15, a coolant flow channel 16, a cone 17, springs 18 and 19 , and the coolant discharge channel 20 .

[0026] The main body 11 includes a front end portion 11t and a base end portion 11b each having a substantially columnar shape. The front end portion 11t and the base end portion 11b are respectively along the axis of the main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com