Novel screening scraper reversed loader

A scraper loader and screening technology, applied in sieves, conveyors, solid separation, etc., can solve the problems of waste of resources, complex systems, and high particle size damage rate of screening materials, and reduce the particle size damage rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

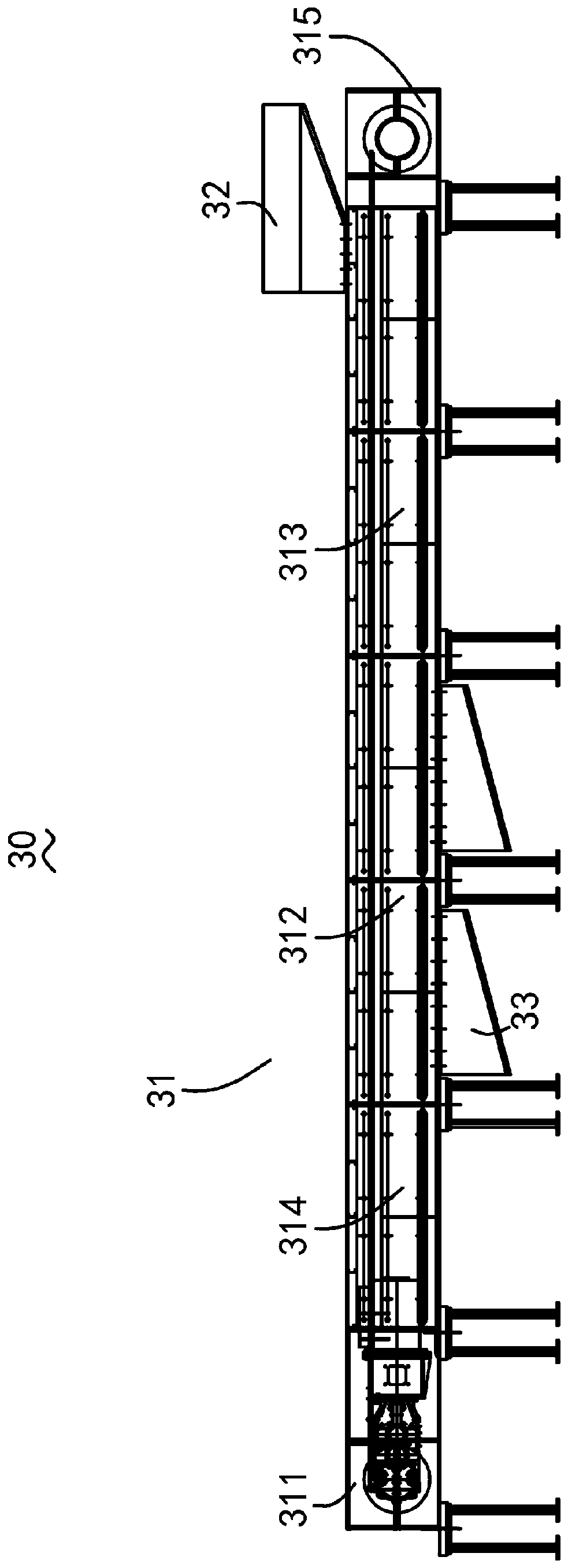

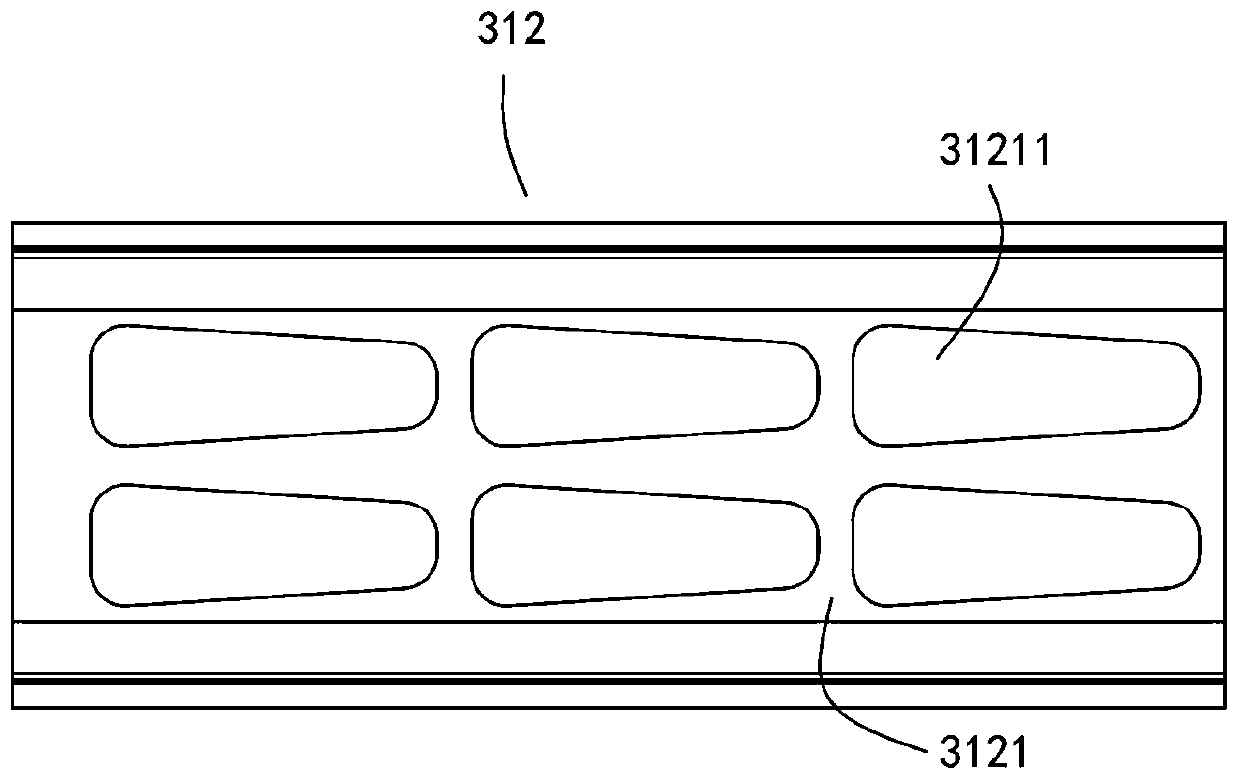

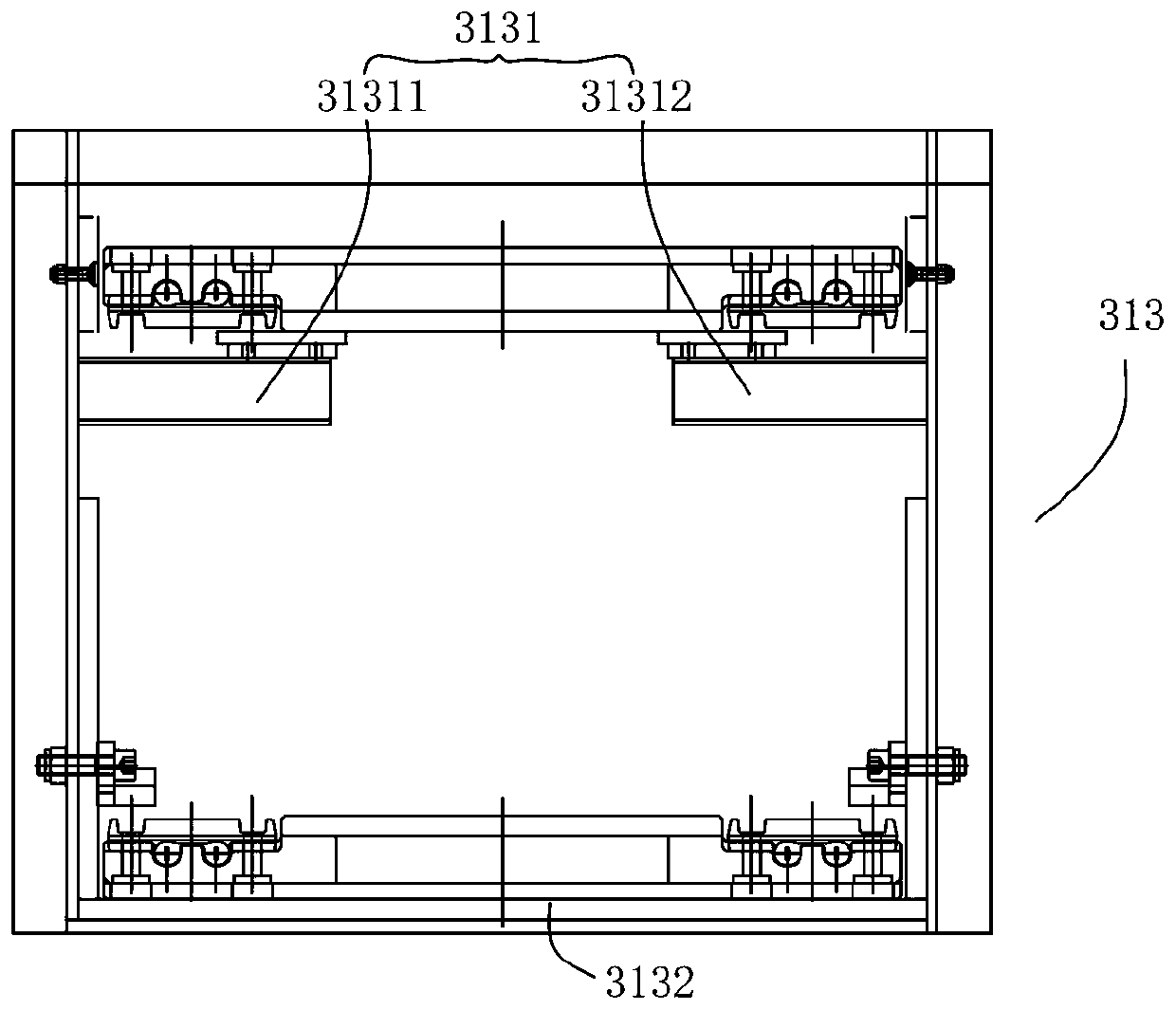

[0017] see Figure 1 to Figure 3 , the embodiment of the present invention provides a new screening scraper transfer machine, including a fuselage 31, a scraper chain is installed in the fuselage 31, and a scraper installed on the scraper chain, the fuselage 31 includes a machine head 311, the first middle slot 312, the second middle slot 313, the third middle slot 314, the tail 315, the nose 311, the third middle slot 314, the first middle slot 312, the second middle slot 313, and the tail 315 from From left to right, they are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com