Ground gas extraction well drillingwell bore structure provided with flexible production casing pipe

A gas drainage and well structure technology, which is applied in casing, drilling equipment, wellbore/well components, etc., can solve the problems of affecting gas drainage effect, small deflection, weak shear deformation ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

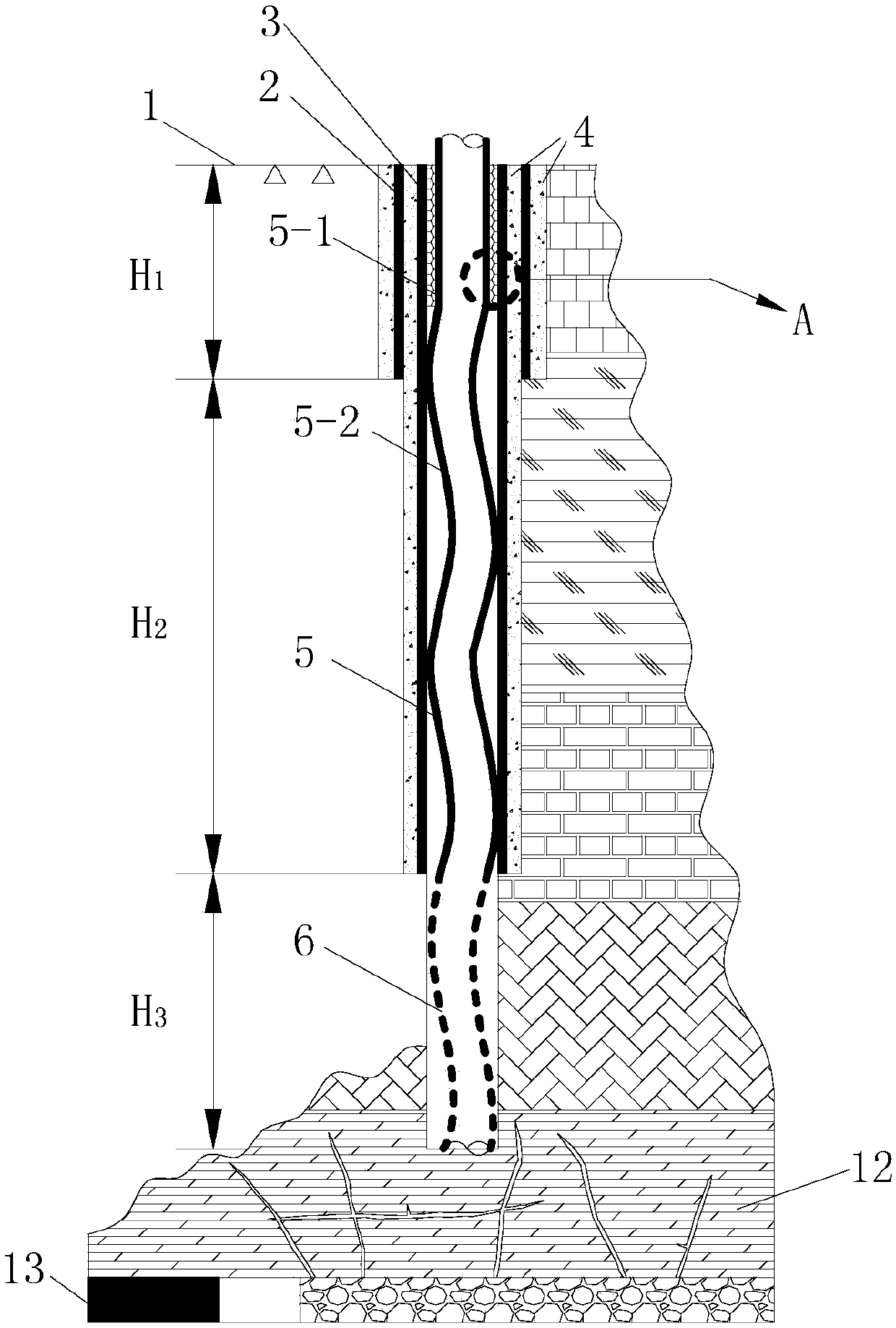

[0016] like figure 1 As shown, the present invention is equipped with a ground gas drainage drilling well structure with flexible production casings. The entire well drilling well is divided into three sections whose apertures are successively reduced from the surface 1 to the mining fracture zone 12: the surface hole section H1 , rock formation hole section H2 and pressure relief drainage hole section H3. A surface casing 2 reinforced with cement slurry 4 is arranged in the surface hole section H1, and a rock casing 3 reinforced with cement slurry 4 is arranged in the rock formation hole section H2 and the surface hole section H1; the surface casing 2 and the rock section casing 3 can be Prevent the well wall of the upper section from collapsing during drilling and affect the normal drilling; pressure relief and drainage section H3 open hole completion. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com