Anti-slip trigger mechanism

A trigger mechanism and anti-slip technology, applied in the mechanical field, can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

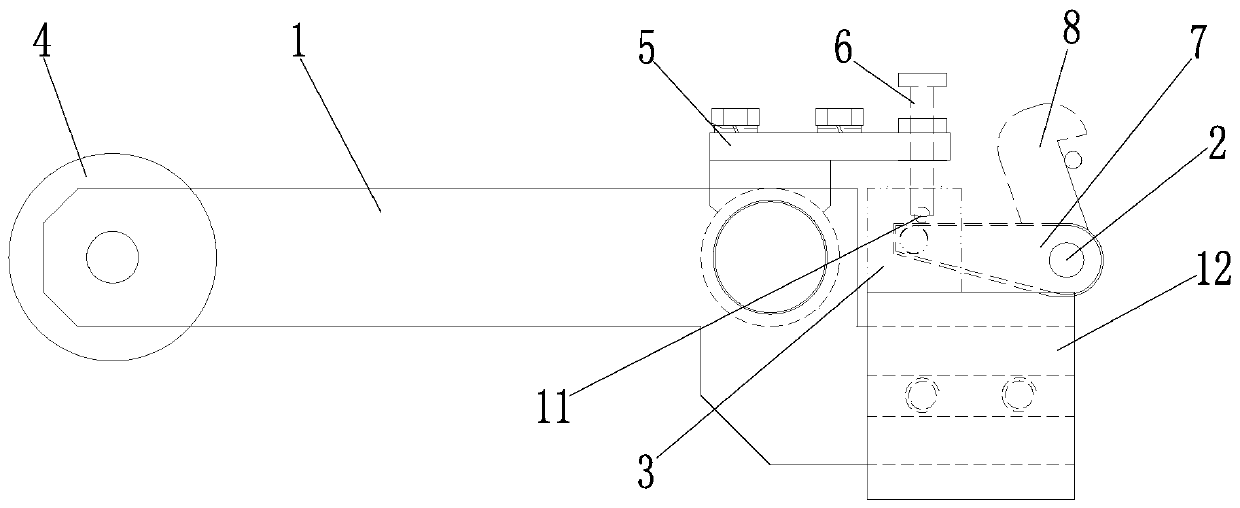

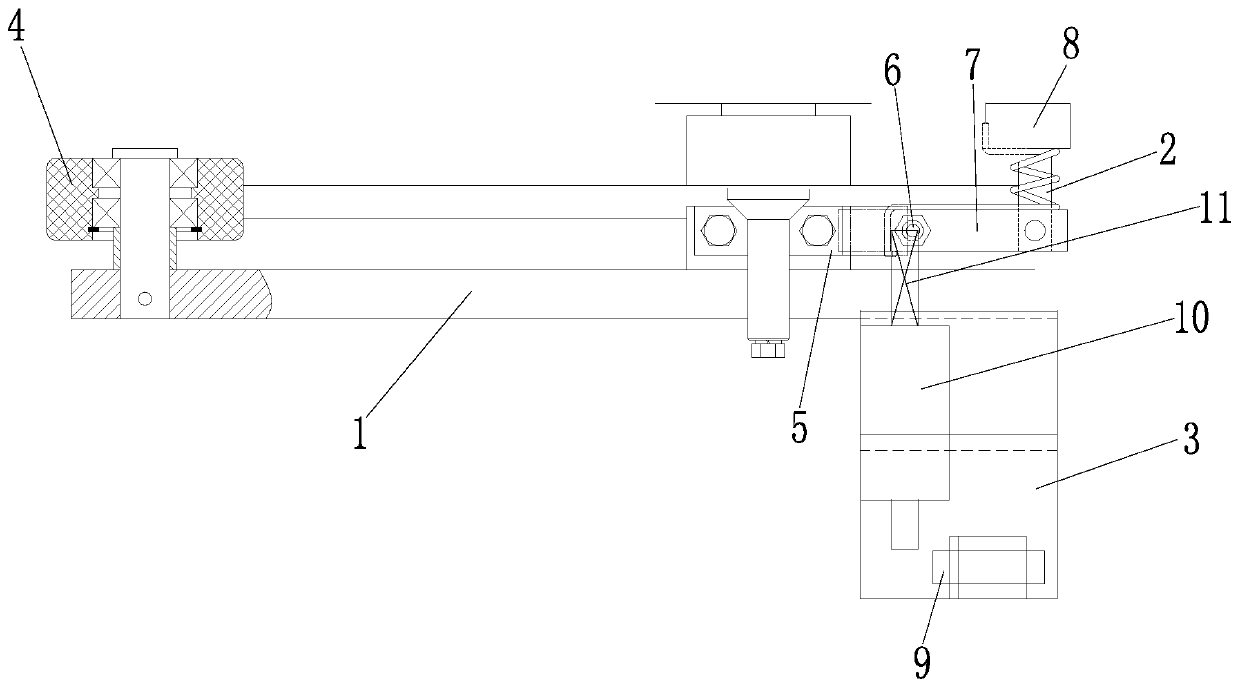

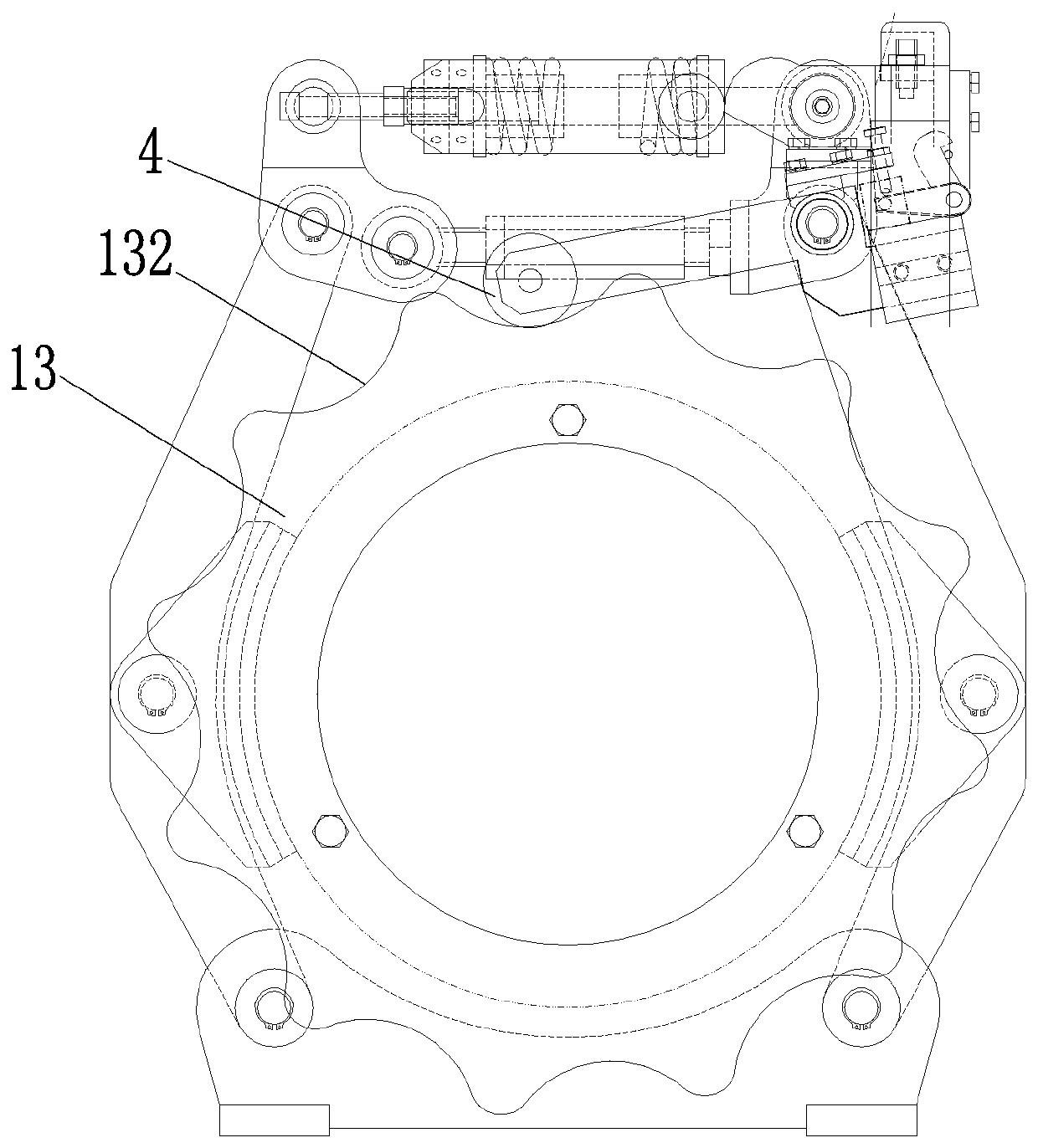

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0013] As shown in the figure, an embodiment of the anti-slip trigger mechanism of the present invention is provided, including a swing arm 1, a brake arm 2, and an angle aluminum bracket 3. The left end of the swing arm 1 is connected to an elastic wheel 4, and the swing arm 1 is also connected to a Press plate 5, trigger screw 6 is provided on press plate 5, small connecting plate 7 and trigger hook 8 are provided on brake arm 2, trigger screw 6 is located above small connecting plate 7, and small connecting plate 7 can be triggered by braking arm 2 The hook 8 moves, and the angle aluminum bracket 3 is provided with a photoelectric sensor switch 9 and an electromagnet 10. The photoelectric sensor 9 switch is used to detect whether the electromagnet 10 is normally sucked back. The electromagnet 10 is connected to the latch 11, and the position of the latch 11 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com