Drying device safety control system

A technology for safety control and drying equipment, applied in the field of information management systems, can solve the problems of low degree of automation, inability to quickly determine the location of alarm occurrence, and easy misoperation in manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

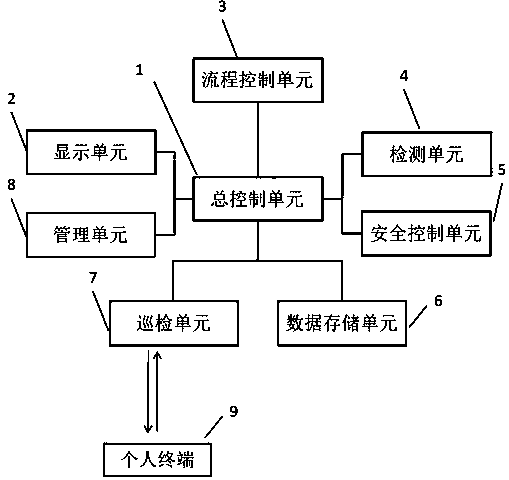

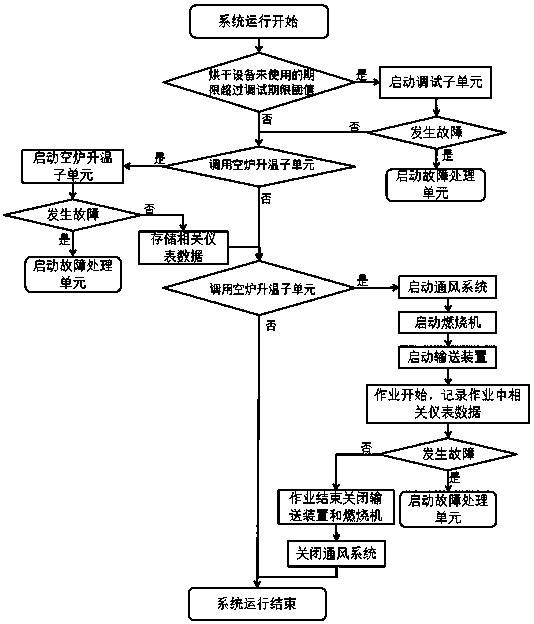

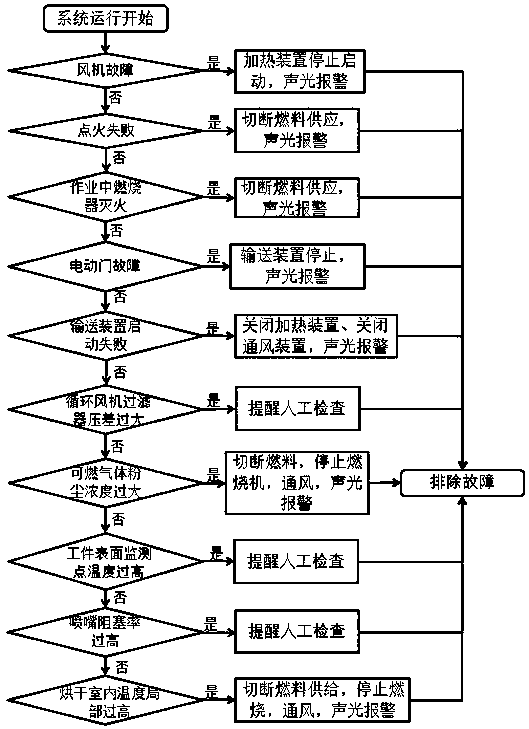

[0028] Such as Figure 1~Figure 3 As shown, it is an embodiment of the present invention, including a display unit 2, a process control unit 3, a detection unit 4, a safety control unit 5, a data storage unit 6, a patrol unit 7, and a management unit 8 respectively connected to the general control unit 1. , , and a personal terminal 9 communicatively connected with the inspection unit 7 .

[0029] The main control unit 1 is connected to the PLC controller on the drying equipment site, controls the underlying physical mechanical equipment and electronic equipment on site through the PLC controller, and processes and distributes the data collected by the PLC controller.

[0030] The display unit 2 displays information in the form of graphics and text, including fault information, alarm information, report information, process control information and detection information detected by the detection unit.

[0031] The process control unit 3 controls the start timing, shutdown timi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com