Ceramic glaze with good wear resistance and high hardness and preparation method thereof

A high-hardness, ceramic glaze technology, applied in the field of ceramic production, can solve the problems of poor antibacterial effect, general aesthetics, devitrification of the glaze, etc., achieve good antibacterial performance, improve aesthetics and artistry, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A ceramic glaze with good wear resistance and high hardness is made of the following raw materials in parts by mass:

[0041] Wollastonite 20g, potassium feldspar 15g, albite 15g, kaolin 10g, diatomaceous earth 10g, silica 5g, alumina 5g, zirconia 5g, titanium carbide 3g, chromium carbide 3g, zircon sand 3g, carbonic acid 2g of barium, 5g of transparent sol, 3g of antibacterial sol, 2g of luminescent crystals and appropriate amount of purified water.

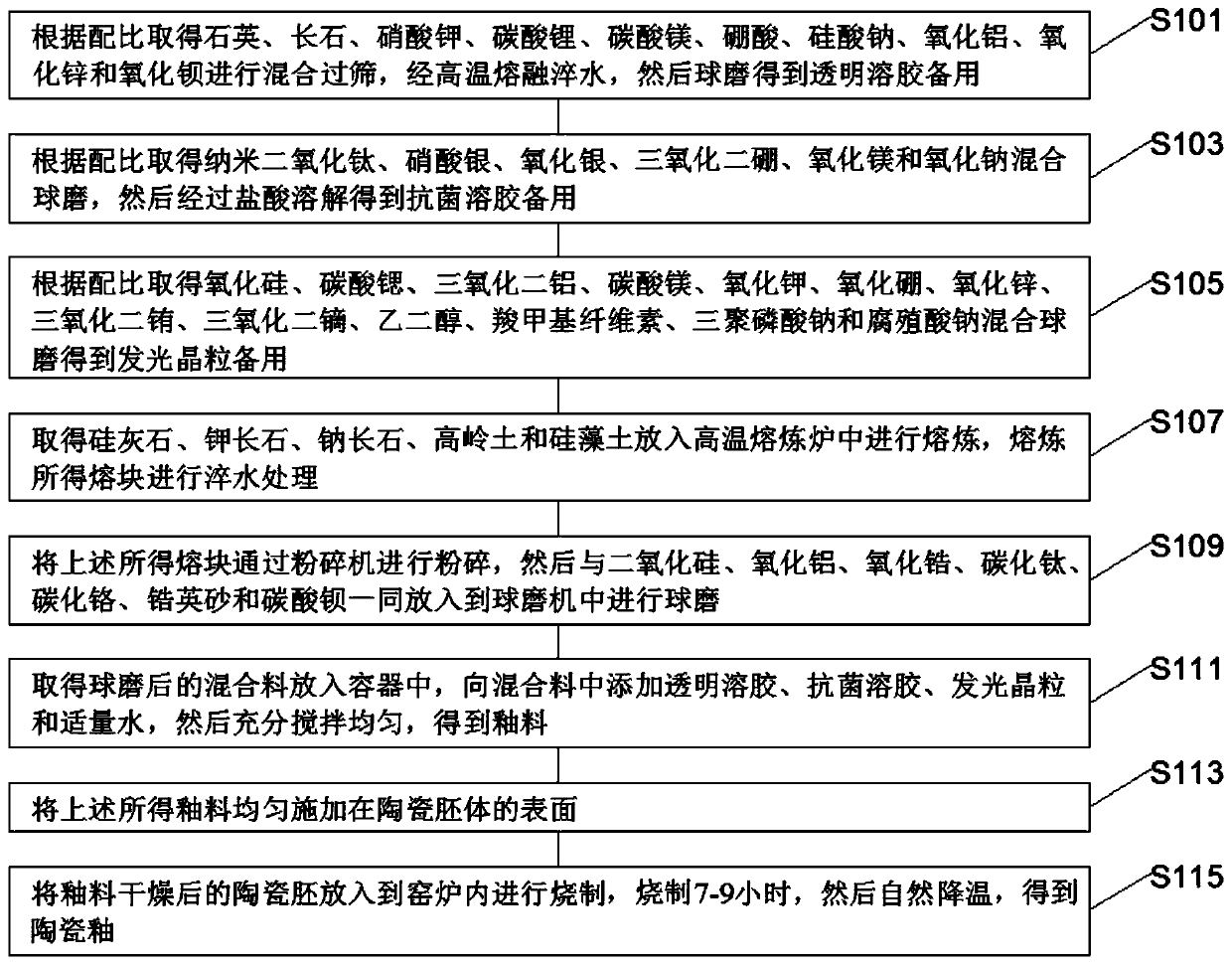

[0042] The preparation of the wear-resistant and high-hardness ceramic glaze comprises the following steps:

[0043]Quartz, feldspar, potassium nitrate, lithium carbonate, magnesium carbonate, boric acid, sodium silicate, aluminum oxide, zinc oxide and barium oxide were obtained according to the ratio, mixed and sieved, melted and quenched at high temperature, and then ball milled to obtain 5g of transparent sol for later use ;

[0044] Obtain nano-titanium dioxide, silver nitrate, silver oxide, boron trioxide, magnesiu...

Embodiment 2

[0052] A ceramic glaze with good wear resistance and high hardness is made of the following raw materials in parts by mass:

[0053] Wollastonite 35g, potassium feldspar 30g, albite 130g, kaolin 20g, diatomaceous earth 15g, silica 10g, alumina 10g, zirconia 7.5g, titanium carbide 6.5g, chromium carbide 5.5g, zircon sand 4g, barium carbonate 3.5g, transparent sol 8.5g, antibacterial sol 5.5g, luminous crystal 4g and appropriate amount of purified water.

[0054] The preparation of the wear-resistant and high-hardness ceramic glaze comprises the following steps:

[0055] Quartz, feldspar, potassium nitrate, lithium carbonate, magnesium carbonate, boric acid, sodium silicate, aluminum oxide, zinc oxide and barium oxide were mixed and sieved according to the ratio, melted and quenched at high temperature, and then ball milled to obtain 8.5g of transparent sol spare;

[0056] Obtain nano-titanium dioxide, silver nitrate, silver oxide, boron trioxide, magnesium oxide and sodium ox...

Embodiment 3

[0064] A ceramic glaze with good wear resistance and high hardness is made of the following raw materials in parts by mass:

[0065] Wollastonite 50g, potassium feldspar 45g, albite 45g, kaolin 30g, diatomaceous earth 20g, silica 15g, alumina 15g, zirconia 10g, titanium carbide 10g, chromium carbide 8g, zircon sand 5g, carbonic acid 5g of barium, 12g of transparent sol, 8g of antibacterial sol, 6g of luminous crystal grains and appropriate amount of purified water.

[0066] The preparation of the wear-resistant and high-hardness ceramic glaze comprises the following steps:

[0067] Quartz, feldspar, potassium nitrate, lithium carbonate, magnesium carbonate, boric acid, sodium silicate, aluminum oxide, zinc oxide and barium oxide were obtained according to the ratio, mixed and sieved, melted and quenched at high temperature, and then ball milled to obtain 12g of transparent sol for later use ;

[0068] Obtain nano-titanium dioxide, silver nitrate, silver oxide, boron trioxide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap