Lock catch structure

A lock and tongue technology, applied in building locks, electric alarm locks, building structures, etc., can solve the problem of being unable to control multiple doors or windows at the same time, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

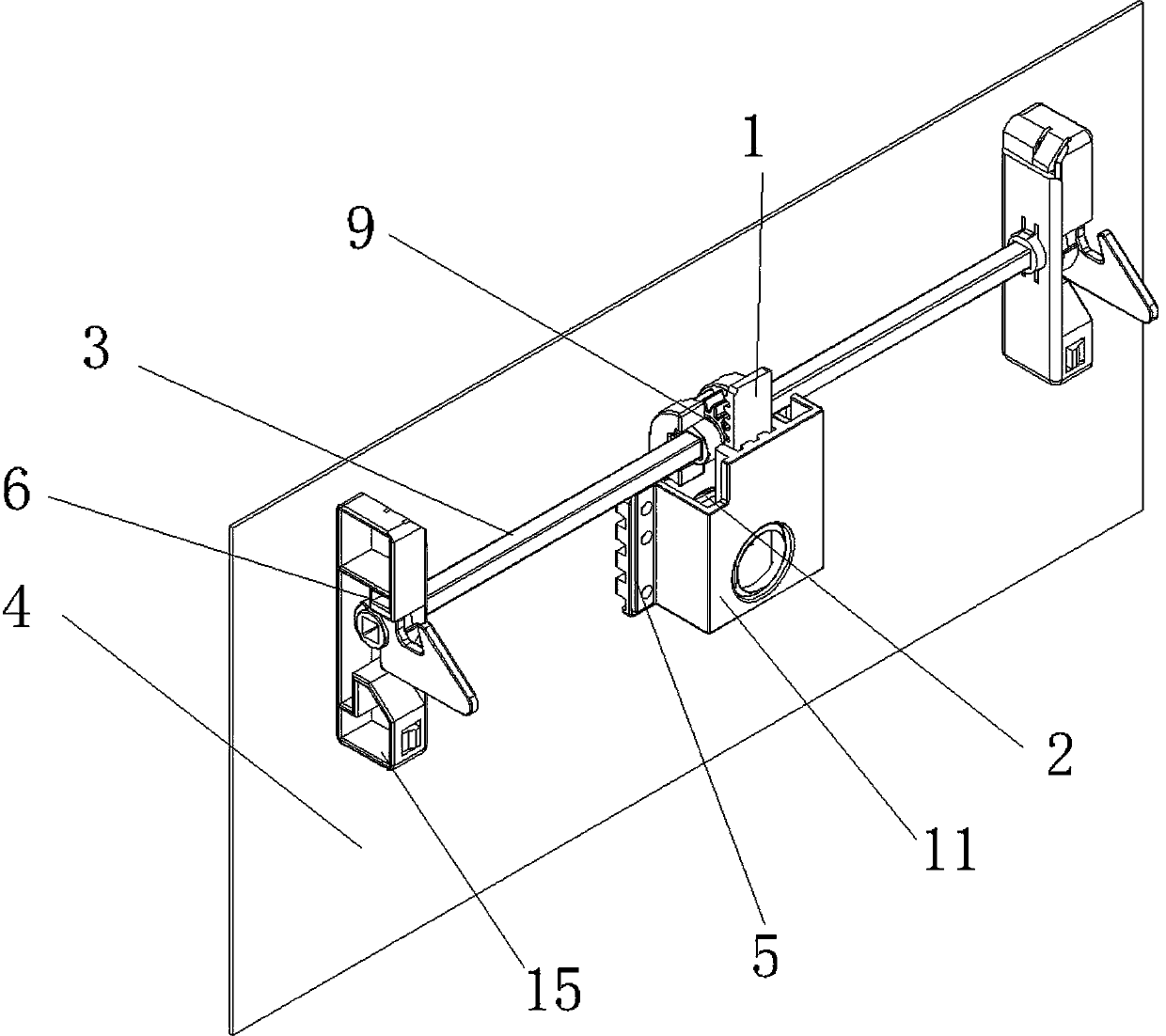

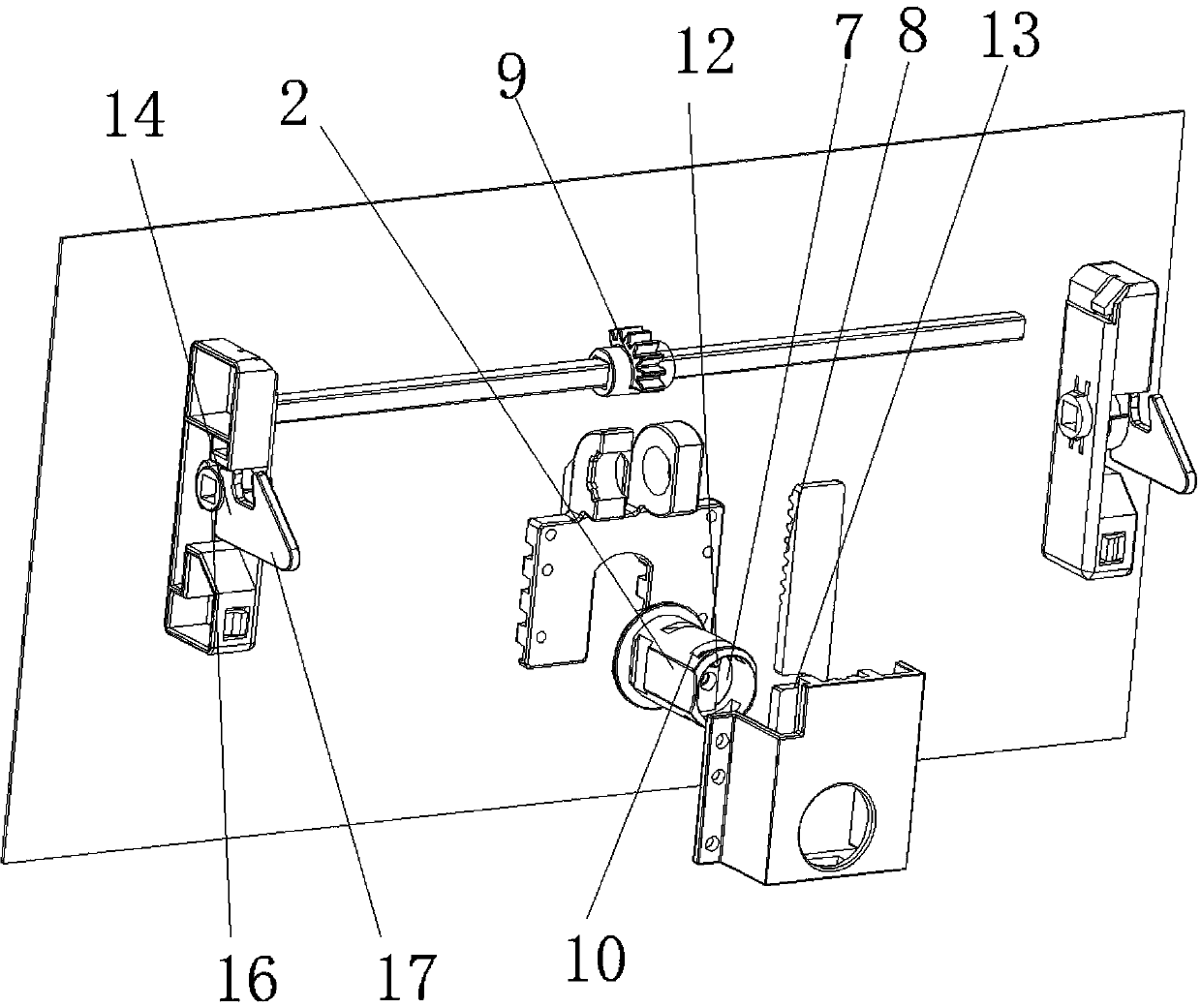

[0032] Such as figure 1 , figure 2 As shown, the technical solutions adopted by the present invention are as follows:

[0033] A lock buckle structure includes a lock tongue 1, a lock core 2, a rotating rod 3, a door panel 4, a lock shell 5 and a pair of hook assemblies 6. One end of the lock core is equipped with a connecting block 7, and one side of the connecting block drives the connecting bolt for reciprocating movement of the bolt. A rack 8 is provided on one side of the bolt; a gear is installed on the rotating rod 9. The gear meshes with the rack, and the pair of hook components are arranged at both ends of the rotating rod. The lock shell is fixed on the door panel, and the lock core is installed in the lock shell. The lock core is provided with a perforation 10 for easy installation of the bolt; a rear cover 11 is installed at the rear end of the lock shell. A convex post 12 is provided on the connecting block, and the convex post is installed on the outer edge of th...

Embodiment 2

[0038] A lock structure includes:

[0039] A lock tongue

[0040] A lock cylinder; one end of the lock cylinder is equipped with a connecting block, one side of the connecting block is used to drive the lock tongue to reciprocate, and one side of the lock tongue is provided with a rack;

[0041] A rotating rod; a gear is mounted on the rotating rod, and the gear meshes with a rack; and

[0042] At least one hook assembly is installed on the rotating rod.

Embodiment 3

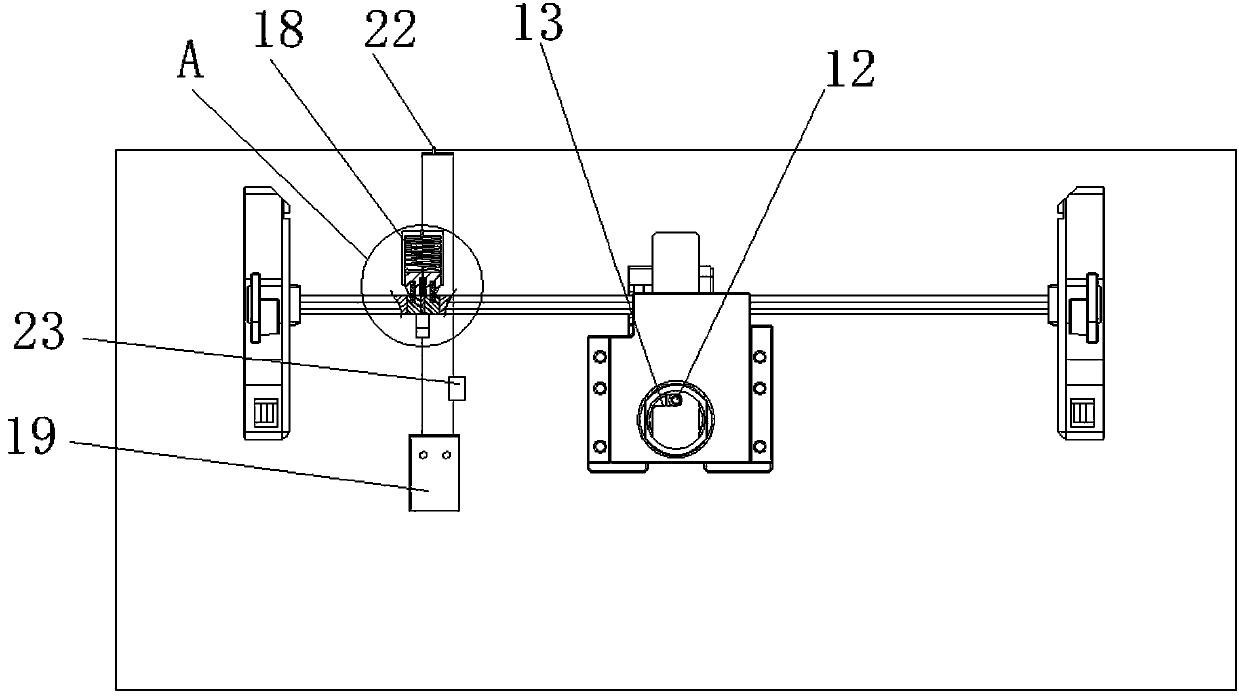

[0044] Such as image 3 , Figure 4 , Figure 5 with Image 6 As shown, the difference between Embodiment 3 and Embodiment 1 is that the locking structure further includes an automatic locking assembly 18, a battery 19, a fixed conductive block 20, a brush sheet 21, a control switch 22 and a buzzer 23. The battery and the fixed conductive block are fixed on the inner side of the door panel, and the power source is sequentially connected with the fixed conductive block, the brush sheet, the automatic locking component, the control switch and the buzzer through the wires. One end of the brush piece is electrically connected to a fixed conductive block. The rotating rod is a hexagonal prism. The rotating rod includes a fixing member 24 and two insulating members 25 located on both sides of the fixing member. A ring-shaped first magnet 26 and a ring-shaped second magnet 27 are respectively provided in the edge surfaces of the two phases. The S pole of the first magnet faces outward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com