Inspection platform for computer circuit board production

A circuit board and computer technology, which is applied in the field of inspection platforms for computer circuit board production, can solve problems such as loss of hot and cold air, hand injuries of staff, etc., and achieve the effects of easy operation, convenient operation, and uniform temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

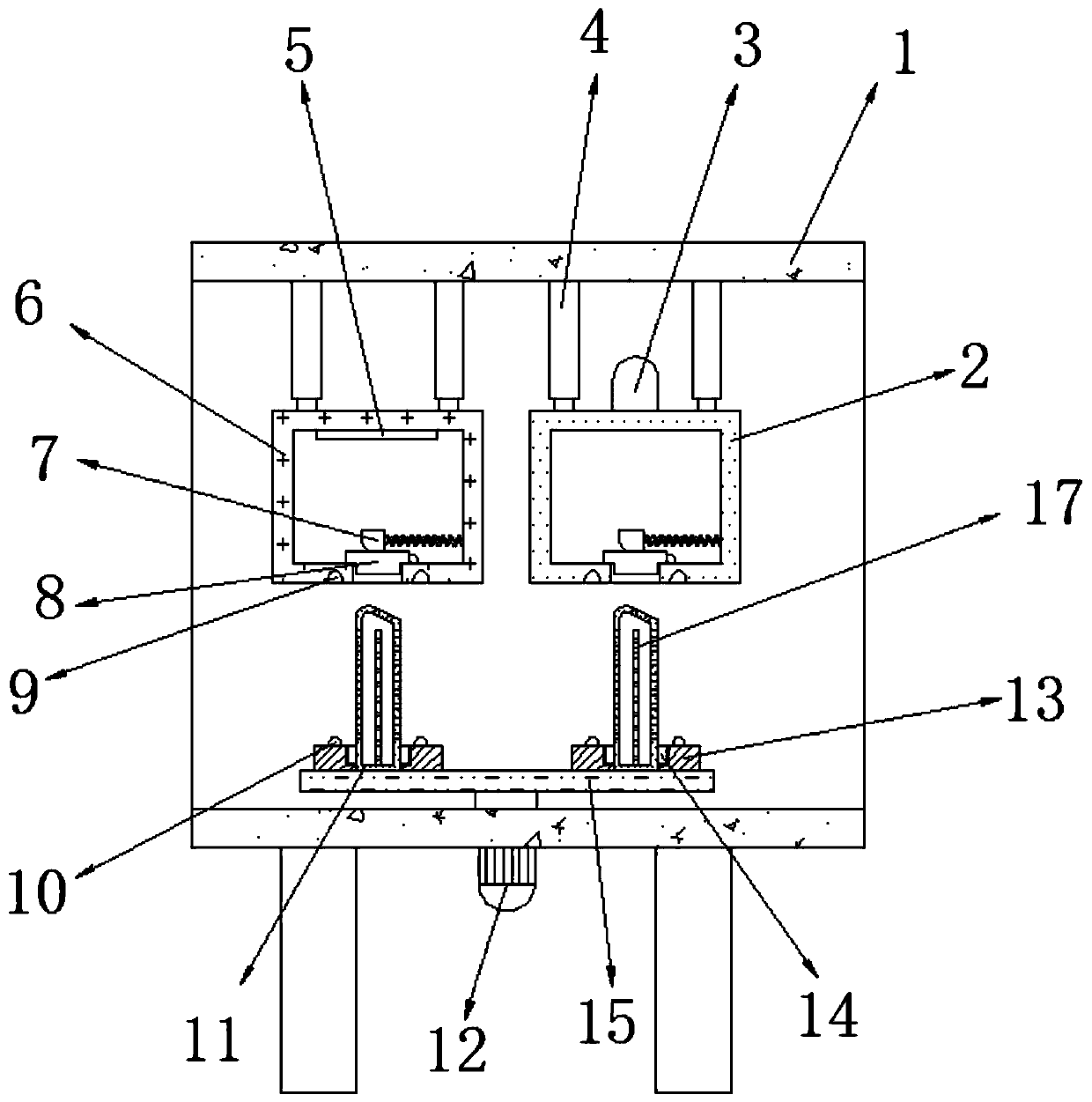

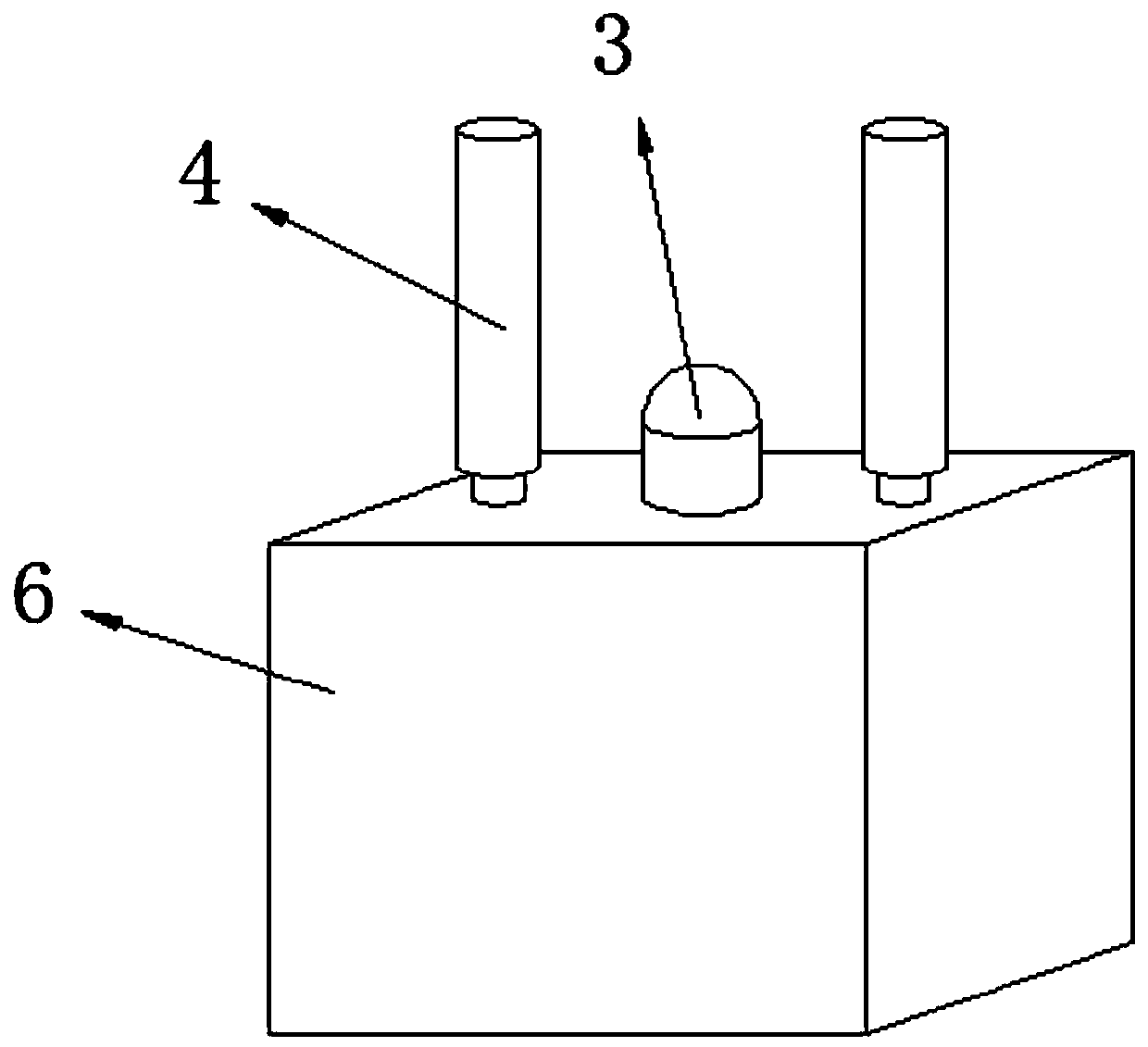

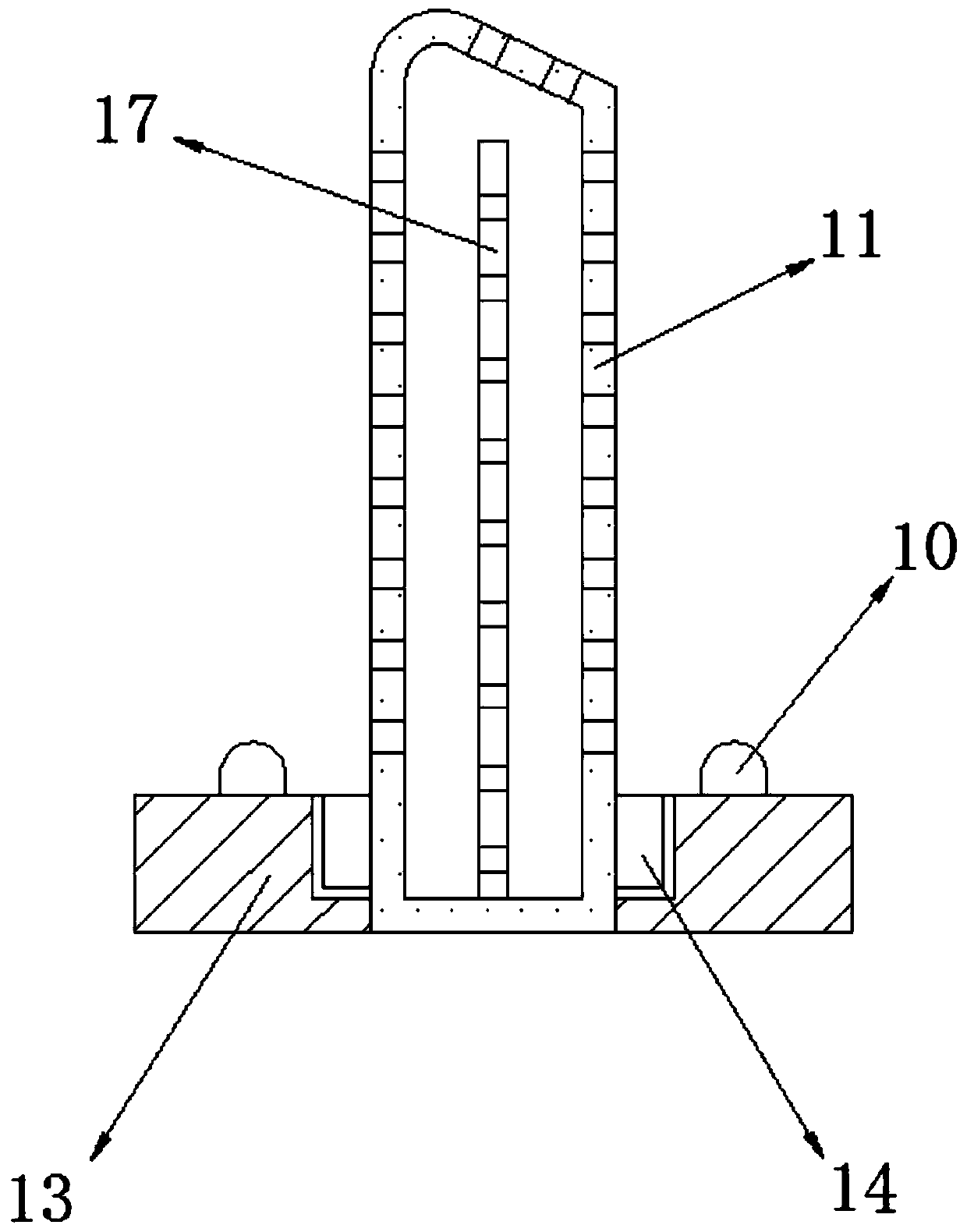

[0029] refer to Figure 1-3 , an inspection platform for computer circuit board production, including a workbench 1, the top inner wall of the workbench 1 is connected with an electric telescopic rod 4 through a fastening bolt, and one end of the electric telescopic rod 4 is connected with a low temperature box 2 through a fastening bolt respectively and the high-temperature box 6, the top outer wall of the low-temperature box 2 is connected with a refrigerator 3 by fastening bolts, and the top inner wall of the high-temperature box 6 is connected with a heating resistance wire 5 by fastening bolts, and the bottom outer walls of the high-temperature box 6 and the low-temperature box 2 are both Perforations are provided, and the bottom inner walls of the high-temperature box 6 and the low-temperature box 2 are all hinged sealing plugs 8, the bottom outer wall of the workbench 1 is connected with a rotating motor 12 by fastening bolts, and the output shaft of the rotating motor 1...

Embodiment 2

[0039] refer to Figure 4 , an inspection platform for computer circuit board production. Compared with Embodiment 1, the outer walls of one side of the low-temperature box 2 and the high-temperature box 6 are connected with a drive motor 18 by fastening bolts, and the two drive motors 18 The output shafts are all connected with fan blades 19 by fastening bolts.

[0040] Working principle: when the housing 11 is inserted into the low-temperature box 2 or the high-temperature box 6, the drive motor 18 drives the fan blade 19 to rotate to stir the air in the box to ensure the uniform temperature in the box and the effect of low-temperature or high-temperature storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com