Steelmaking workshop construction operation intelligent safety alarm system and alarm method thereof

A security alarm and intelligent technology, applied in the direction of alarms, instruments, etc., can solve problems such as hidden safety hazards and large labor, and achieve the effect of reducing production costs, ensuring safety, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

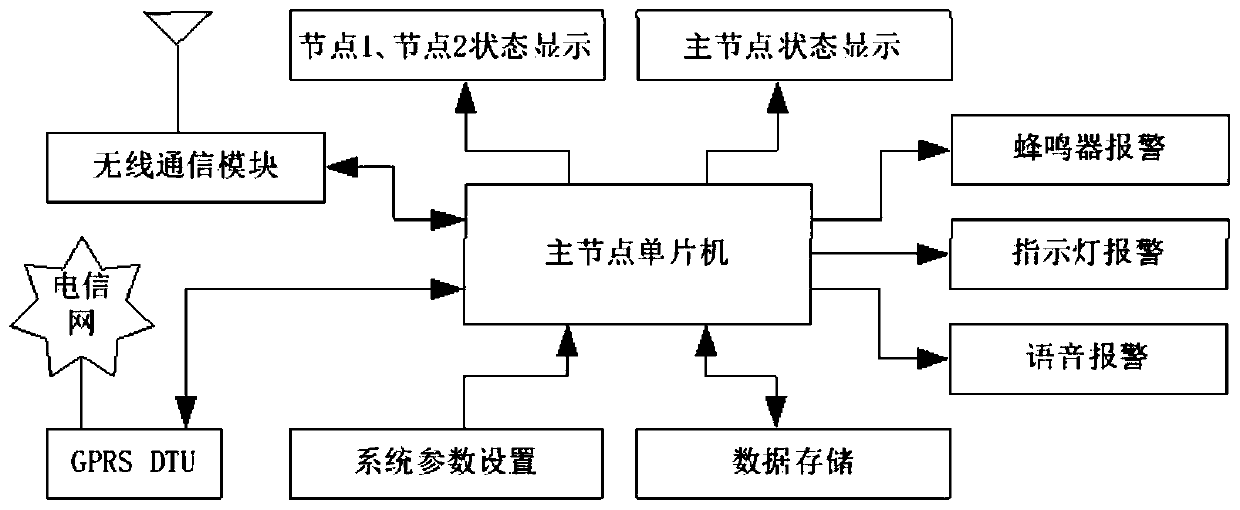

[0060] An intelligent security alarm system for construction operations in a steelmaking workshop in this embodiment includes two ranging sensor units 2 (ie, detection nodes) with the same function and an alarm master control unit 1 (ie, a master node). and the temporary nature of the maintenance task, the task cycle and the uncertainty of the construction site, and in order to ensure production efficiency, the driving vehicle 6 must not stop when it is running. It is directly installed in the steelmaking workshop, without any modification or installation of production equipment, and does not have any impact on production.

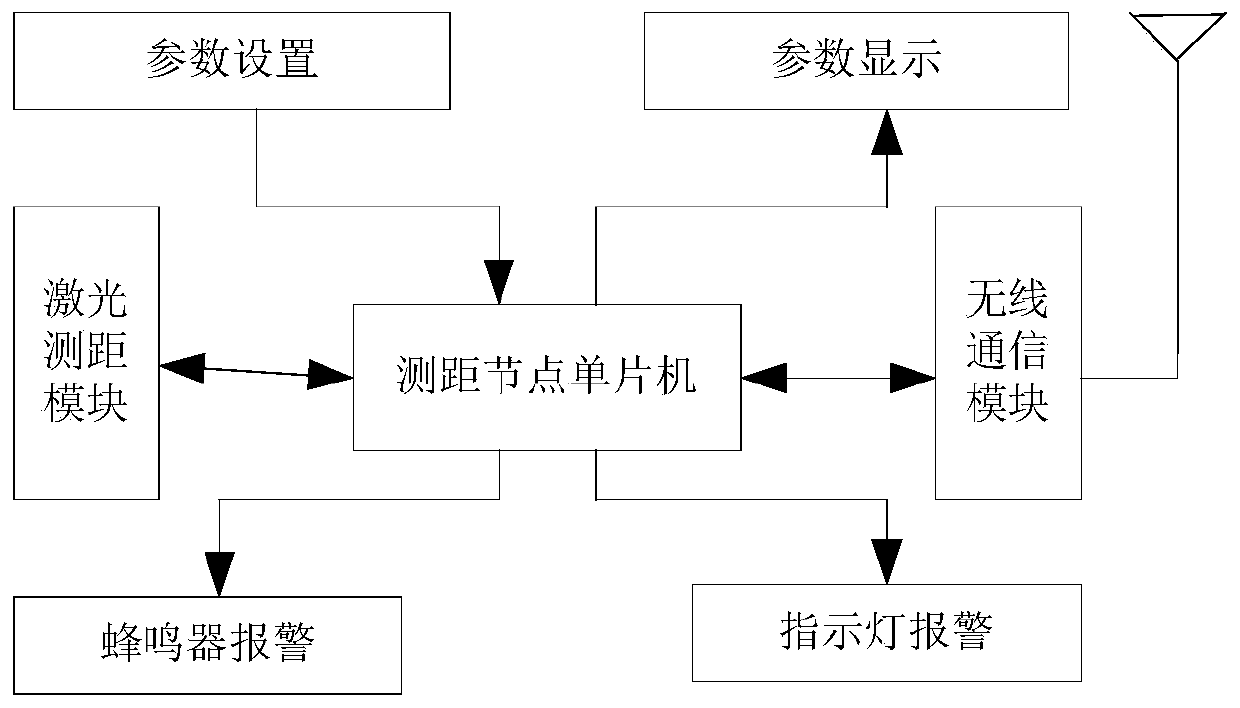

[0061] combine figure 1 , the ranging sensing unit 2 of the present embodiment includes a single-chip microcomputer, a laser ranging module, a wireless communication module, a parameter setting module, a parameter display module and an acousto-optic alarm module, each module is electrically connected, and the driving vehicle 6 passes through the ranging se...

Embodiment 2

[0071] An intelligent safety alarm method for construction operations in a steelmaking workshop in this embodiment is specifically as follows:

[0072] Step 1. System communication matching debugging

[0073] Adjust the relevant communication parameters through parameter setting to ensure that the communication between the two ranging sensing units 2 and the alarm main control unit 1 is normal.

[0074] Step 2. Install the system

[0075] A special bracket is installed on the steel column 8 near the loading area 3 and the unloading area 5 to fix the two ranging sensing units 2, and the alarm master control unit 1 is placed near the construction operation area 4.

[0076] The basis for installing the location of the distance measuring sensor unit 2 is that the sum of the reaction time of the operator and the time for walking away from the scene is less than the time for the driving vehicle 6 to travel from the distance measuring sensor unit 2 to the alarm main control unit 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com