A kind of gypsum tofu regulated by oligosaccharides and its preparation method

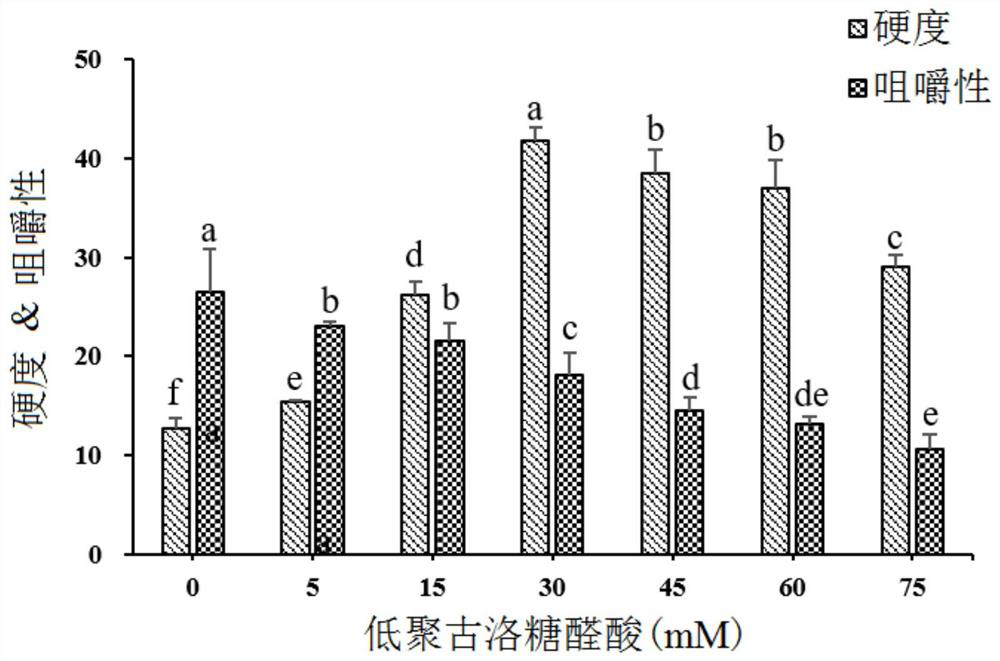

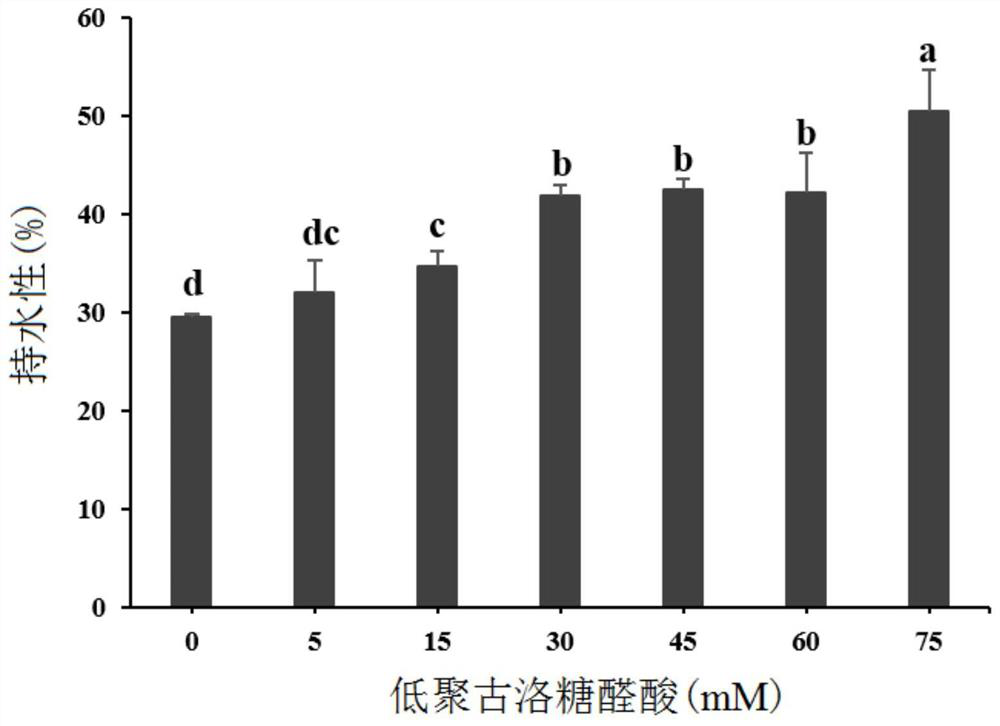

A technology of oligosaccharides and gypsum, applied in dairy products, food science, cheese substitutes, etc., can solve problems affecting consumers' health and stones, achieve dense tofu gel structure, easy to obtain raw materials, and reduce chewiness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation process of gypsum tofu regulated by oligosaccharide is as follows:

[0033] 1) Weigh 100g soybeans, soak them in 300g water, soak them at 25°C for 9 hours, wash them repeatedly for 3 times, mix and squeeze the juice according to the mass ratio of water and soybean dry matter at 6:1, first treat at 3000rpm for 3min, then at 5000rpm for 2min; 100 mesh Sieve and filter 3 times to remove soybean dregs, and finally obtain soybean milk with a protein mass fraction of 6%.

[0034] 2) Weigh 0.1042 g of oligoguluronic acid, dissolve it in 10 ml of water, and dissolve on a roller instrument at 200 rpm for 12 hours to obtain 50 mM oligoguluronic acid mother liquor.

[0035] 3) Weigh 1.0320 g of calcium sulfate dihydrate, dissolve it in 10 ml of water, and obtain a 300 mM calcium sulfate suspension mother liquor.

[0036] 4) get above-mentioned soybean milk 8.5ml in 20ml reagent bottle, heat 5min at 100 DEG C to make soybean protein denaturation, then cool down to ...

Embodiment 2

[0038] The preparation process of gypsum tofu regulated by oligosaccharide is as follows:

[0039]1) Weigh 100g soybeans, soak them in 300g water, soak them at 25°C for 9 hours, wash them repeatedly for 3 times, mix and squeeze the juice according to the mass ratio of water and soybean dry matter at 6:1, first treat at 3000rpm for 3min, then at 5000rpm for 2min; 100 mesh Sieve and filter 3 times to remove soybean dregs, and finally obtain soybean milk with a protein mass fraction of 6%.

[0040] 2) Weigh 0.3126 g of oligoguluronic acid, dissolve it in 10 ml of water, and dissolve on a roller instrument at 200 rpm for 12 hours to obtain 150 mM oligoguluronic acid mother liquor.

[0041] 3) Weigh 1.0320 g of calcium sulfate dihydrate, dissolve it in 10 ml of water, and obtain a 300 mM calcium sulfate suspension mother liquor.

[0042] 4) get above-mentioned soybean milk 8.5ml in 20ml reagent bottle, heat 5min at 100 DEG C to make soybean protein denaturation, then be cooled to ...

Embodiment 3

[0044] The preparation process of gypsum tofu regulated by oligosaccharide is as follows:

[0045] 1) Weigh 100g soybeans, soak them in 300g water, soak them at 25°C for 9 hours, wash them repeatedly for 3 times, mix and squeeze the juice according to the mass ratio of water and soybean dry matter at 6:1, first treat at 3000rpm for 3min, then at 5000rpm for 2min; 100 mesh Sieve and filter 3 times to remove soybean dregs, and finally obtain soybean milk with a protein mass fraction of 6%.

[0046] 2) Weigh 0.6252 g of oligoguluronic acid, dissolve it in 10 ml of water, and dissolve on a roller instrument at 200 rpm for 12 hours to obtain 300 mM oligoguluronic acid mother liquor.

[0047] 3) Weigh 1.0320 g of calcium sulfate dihydrate, dissolve it in 10 ml of water, and obtain a 300 mM calcium sulfate suspension mother liquor.

[0048] 4) get above-mentioned soybean milk 8.5ml in 20ml reagent bottle, heat 5min at 100 DEG C to make soybean protein denaturation, then be cooled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com