Livestock heart meat pie and preparation method thereof

A technology for livestock and poultry and meat pies, which is applied in the direction of yeast-containing food ingredients, oil-containing food ingredients, food science, etc., and can solve the problems of poor gel performance, inability to form, and low content of saturated fatty acids in livestock and poultry heart meat, and achieve the appearance Good formability, elastic taste, and the effect of reducing the content of saturated fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

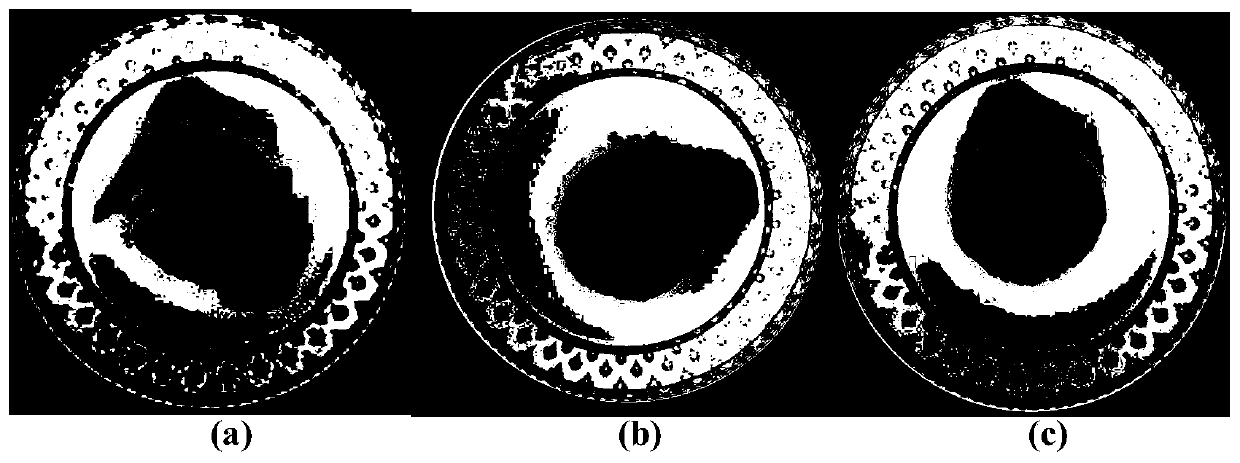

Image

Examples

Embodiment 1

[0026] The present invention provides a kind of duck heart cake, and it is made by following steps:

[0027] S0, pretreatment: wash away bloodstains and dirt on the surface of the duck heart, remove connective tissue, fascia and fat, then place it in clear water, and add 2% of salt and 2% of the quality of the clear water to the clear water After mixing the yeast, soak for 2 hours.

[0028] S1, mincing: mince the pretreated 50 parts by weight of duck heart with a meat grinder to obtain minced duck heart;

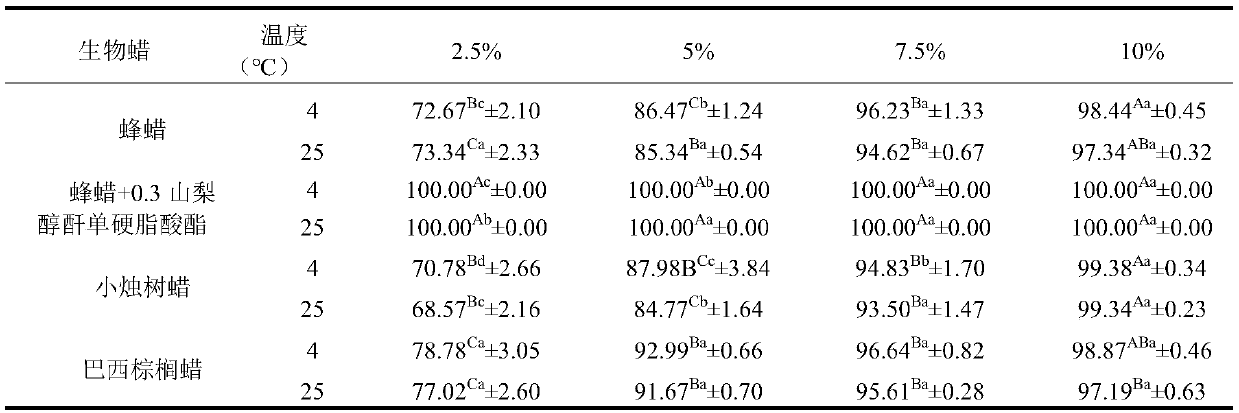

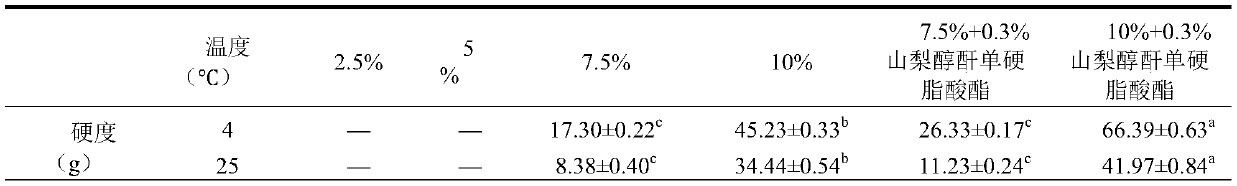

[0029] S2, one-time physical recombination: add 10 parts by weight of gel oil, 0.8 parts by weight of table salt, 1.7 parts by weight of egg whites, 0.2 parts by weight of sodium carbonate and 0.1 parts by weight of compound phosphate into the heart of the obtained broken duck, and stir evenly Afterwards, seal and stand still for 2h to obtain minced meat; the preparation method of the gel oil is: add beeswax and 0.3% sorbitan monostearate that account for 10% of the rapesee...

Embodiment 2

[0034] The invention provides a kind of beef heart cake, and it is made by following steps:

[0035] S0, pretreatment: wash away bloodstains and dirt on the surface of beef heart, remove connective tissue, fascia and fat, then place it in clear water, and add 2% of salt and 2% of the quality of the clear water to the clear water After mixing the yeast, soak for 2 hours.

[0036] S1. Grinding: Grinding 60 parts by weight of pretreated beef heart with a meat grinder to obtain crushed beef heart;

[0037] S2. One-time physical recombination: add 15 parts by weight of gel oil, 1 part by weight of table salt, 2.8 parts by weight of egg white, 0.3 parts by weight of sodium carbonate and 0.3 parts by weight of compound phosphate into the heart of the obtained minced beef, and stir evenly Afterwards, seal and stand still for 2h to obtain minced meat; the preparation method of the gel oil is: add beeswax and 0.3% sorbitan monostearate that account for 10% of the rapeseed oil quality t...

Embodiment 3

[0042] The invention provides a kind of pig heart cake, and it is made by following steps:

[0043] S0, pretreatment: wash away bloodstains and dirt on the surface of the pig heart, remove connective tissue, fascia and fat, then place it in clear water, and add 2% of salt and 2% of the quality of the clear water to the clear water After mixing the yeast, soak for 2 hours.

[0044] S1, mincing: mincing the pretreated 56 parts by weight of pig hearts with a meat grinder to obtain minced livestock and poultry hearts;

[0045] S2. One-time physical recombination: add 13 parts by weight of gel oil, 0.9 parts by weight of table salt, 2.1 parts by weight of egg white, 0.26 parts by weight of sodium carbonate and 0.24 parts by weight of compound phosphate into the heart of the obtained minced pig, and stir evenly Afterwards, seal and stand still for 2h to obtain minced meat; the preparation method of the gel oil is: add beeswax and 0.3% sorbitan monostearate that account for 10% of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com