Large bearing heating device for mining machinery

A bearing heating and mechanical technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to transport, low installation cost, and high price, and achieve the effects of convenient disassembly and assembly, enhanced strength, and convenient heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

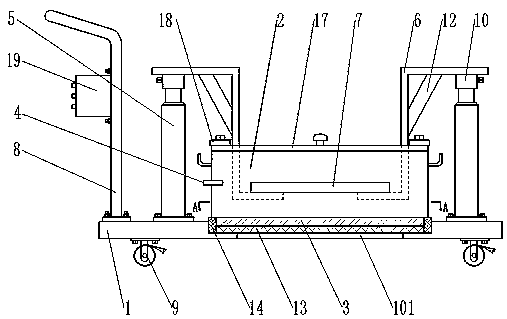

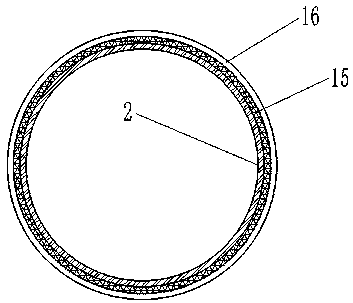

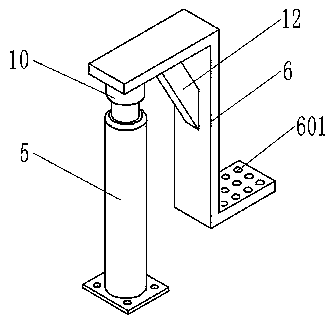

[0036] figure 1 , image 3 and Figure 4Among them, a large-scale bearing heating device for mining machinery, including a base 1 and a heating pot 2, a groove is arranged on the base 1, an electric heating plate 3 is arranged in the groove, the heating pot 2 is set on the electric heating plate 3, and the heating The outer bottom of the pot 2 is attached to the upper surface of the electric heating plate 3, and a temperature sensor 4 is installed on the side wall of the heating pot 2; an electric cylinder 5 is vertically arranged on the left and right sides of the heating pot 2 on the base 1, The specifications and models of the two electric cylinders 5 are the same and start and stop synchronously. The top end of the telescopic rod of the electric cylinder 5 is connected with a Z-shaped plate 6. The plate 6 can not only extend into the heating pot 2 under the action of the electric cylinder 5, but also rise to the top of the heating pot 2 under the action of the electric c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com