Automobile seat shock absorber and automobile seat

A technology for car seats and shock absorbers, which is applied to vehicle seats, seat suspension devices, seat heating/ventilation devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

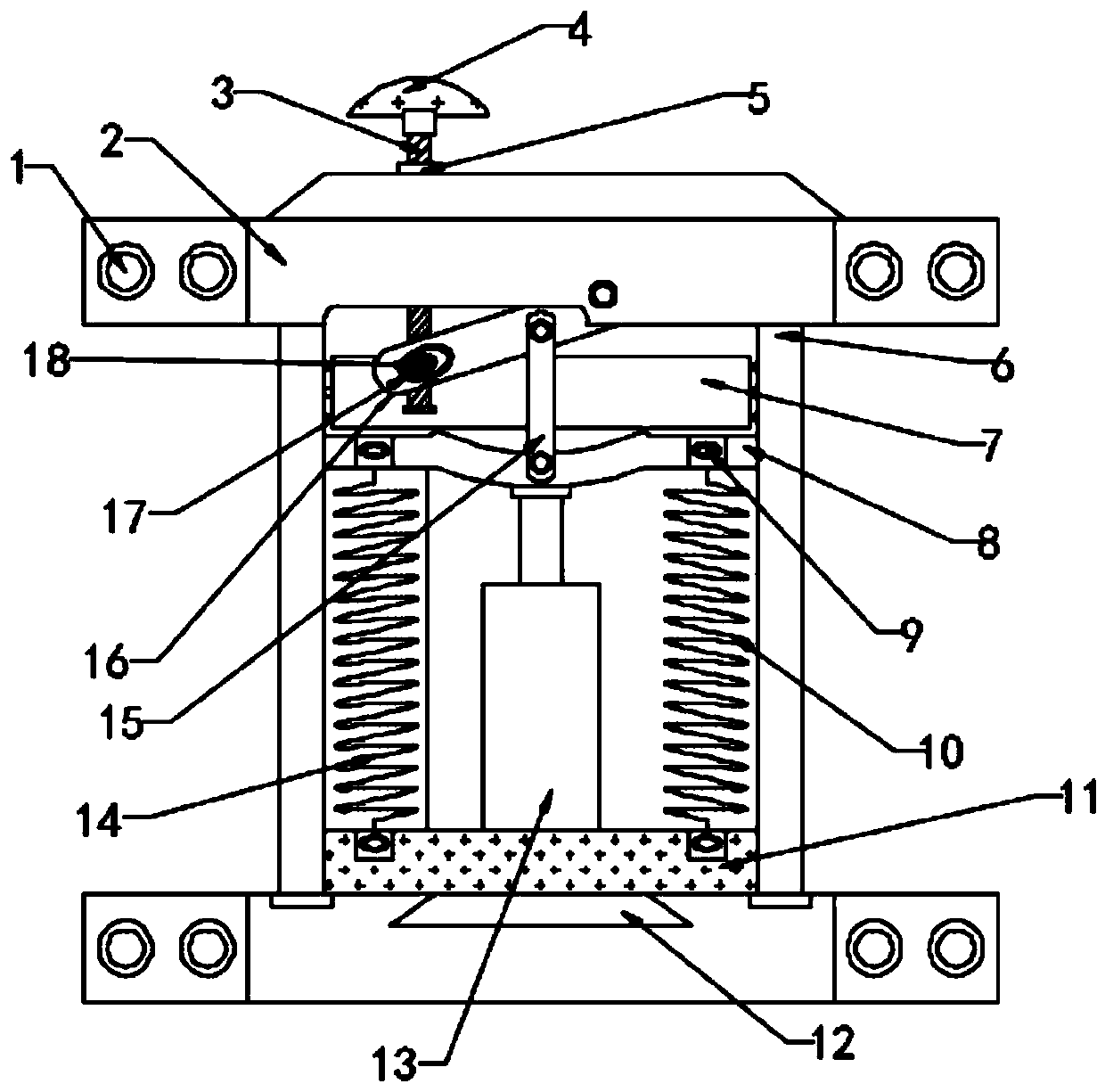

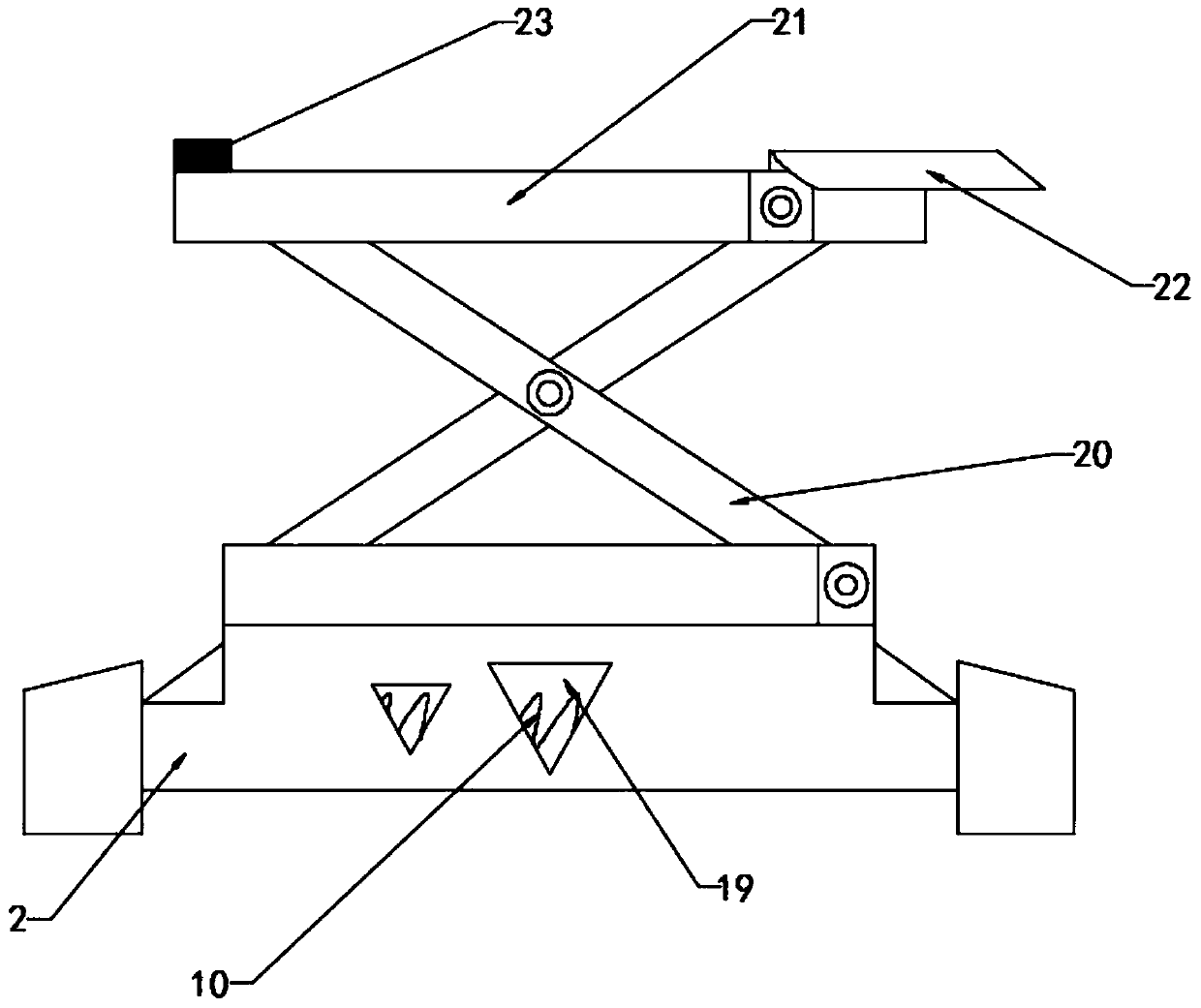

[0017] See figure 1 with figure 2 , A car seat shock absorber provided in Embodiment 1 of the present invention, the car seat shock absorber includes: a shock absorber body 2, two sides of the shock absorber body 2 are provided with sliding rails 6, two sliding A buffer assembly is arranged between the rails 6, a sliding piece 8 is slidably installed inside the sliding rail 6, and the sliding piece 8 is connected with the buffer assembly;

[0018] The upper end of the sliding sheet 8 is provided with a bracket 20, the number of brackets 20 is four, the two brackets 20 on the side constitute a group, and the two brackets 20 in a group are movably connected by a pin hinge; One end of one of the brackets 20 is hinged and movably mounted on the shock absorber body 2, and one end of the other bracket 20 in the group is installed and fixed on the sliding plate 8 through the second mounting hole 9 by bolts; two brackets 20 in the group A pallet 21 is installed at the upper end;

[0019...

Embodiment 2

[0023] In the second embodiment of the present invention, a buffer assembly is provided. The buffer assembly includes a first buffer member and a second buffer member. The first buffer member and the second buffer member are distributed on the sliding sheet 8 between the sliding rails 6 Front and back

[0024] Further, the first buffer member includes a damper 13 and a compression spring. One end of the damper 13 is connected and fixed with the sliding plate 8, the other end of the damper 13 is connected and fixed with a fixed block 11, and the fixed block 11 is installed and fixed on the shock absorber body. 2 on; one end of the compression spring is connected and fixed with the sliding plate 8, and the other end of the compression spring is connected and fixed with the sliding plate 8;

[0025] Specifically, the number of the compression springs is two, namely, the first compression spring 10 and the second compression spring 14. The first compression spring 10 and the second com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com