A full flow electronic expansion valve

An electronic expansion valve and valve seat technology, which is applied in the direction of lifting valve, valve device, valve details, etc., can solve the problems of difficult assembly and installation of refrigeration accessories, increase the risk of refrigerant leakage, and occupy a large space, so as to reduce the pipeline Overall length, reduction of machining amount, smooth flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

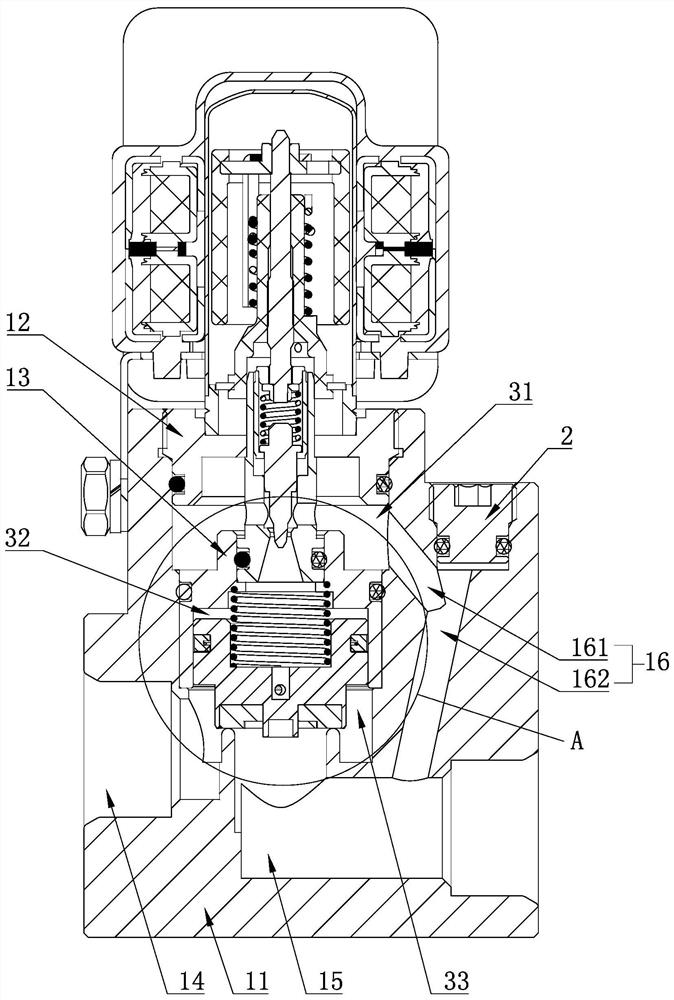

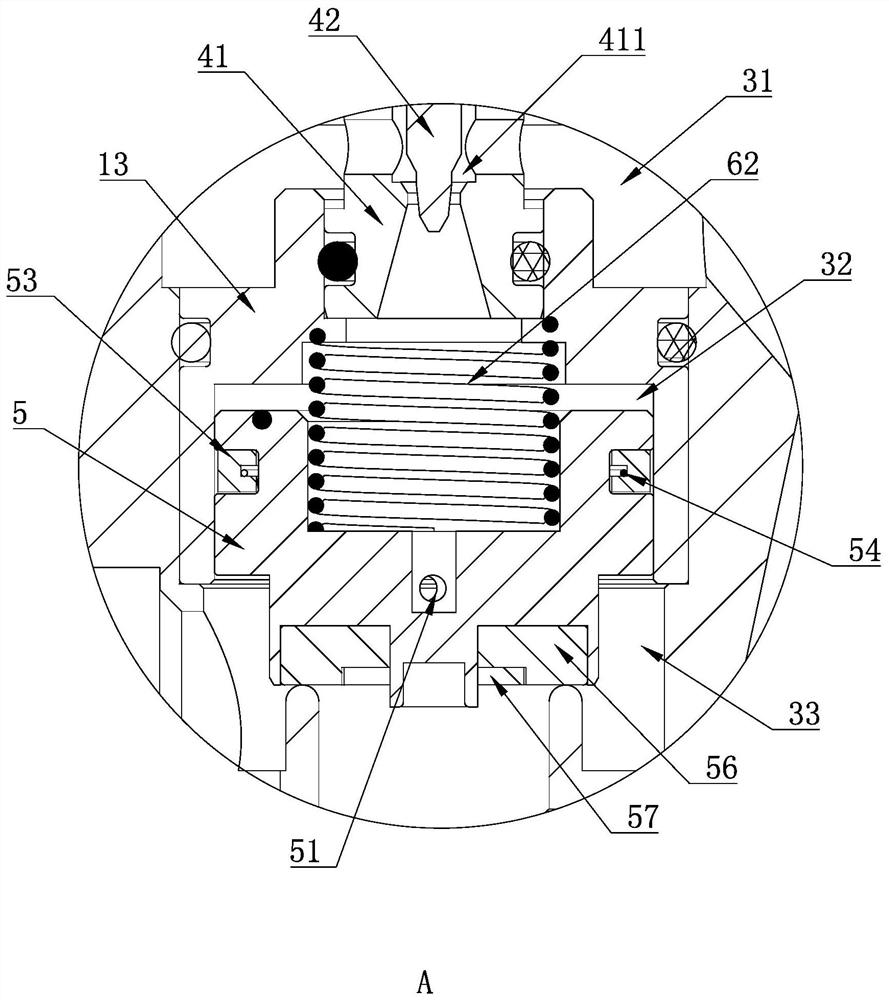

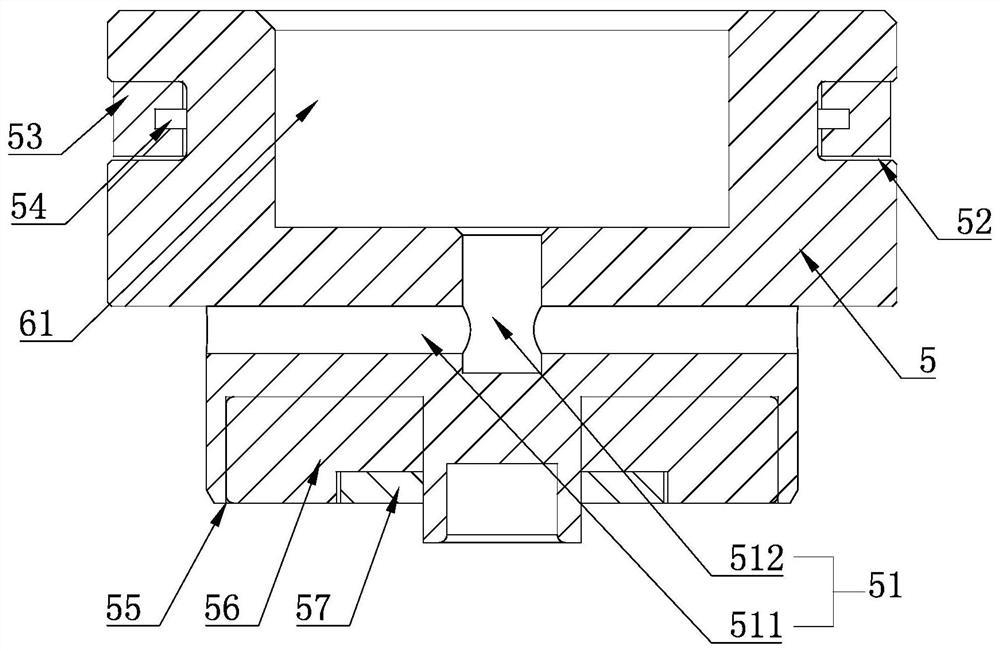

[0031] refer to Figure 1 to Figure 3 The embodiment of a full flow electronic expansion valve of the present invention will be further described.

[0032] A full-flow electronic expansion valve includes a valve seat assembly and a valve core assembly, the valve seat assembly includes a valve seat 11 and a valve cover 12, and the valve seat 11 is provided with a valve cavity, a first channel 14 for entering the refrigerant and a valve for discharging the refrigerant. In the second passage 15, the valve cavity includes an upper cavity 31, a middle cavity 32 and a lower cavity 33, the top of the valve seat 11 is provided with a valve cover 12 that closes the top of the valve cavity, and the valve cover 12 and the valve seat 11 pass fine thread Connection, high connection strength, the valve cover 12 and the valve seat 11 are provided with a first groove and a first O-ring on the side wall, and the first O-ring is partially located in the first groove to prevent refrigerant from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com