A connection structure between torsion bar and rocker arm of rolling stock anti-rolling torsion bar device

A technology of anti-roll torsion bar and connection structure, which is applied in the direction of lateral relative movement between the chassis and the bogie, transportation and packaging, railway car body parts, etc. Assembly, low connection strength and other problems, to achieve the effect of improving anti-rolling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

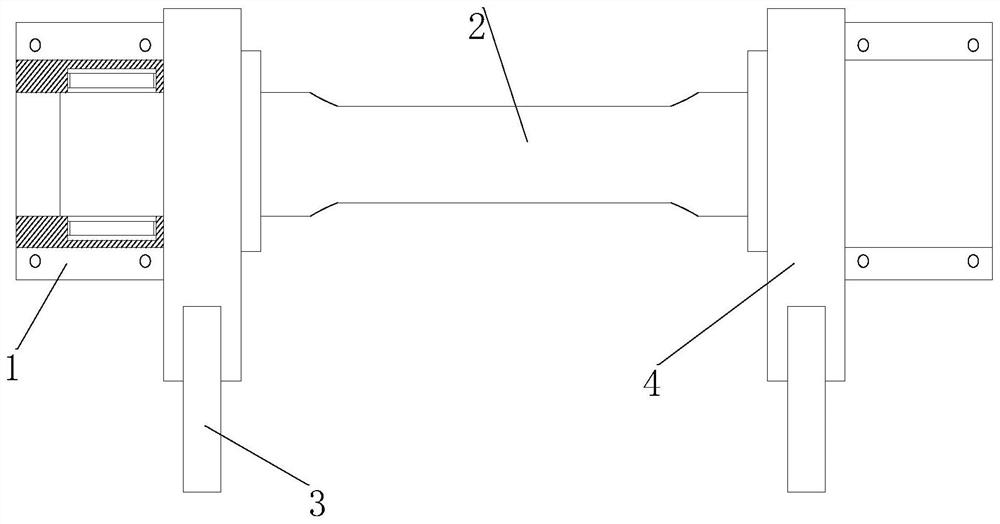

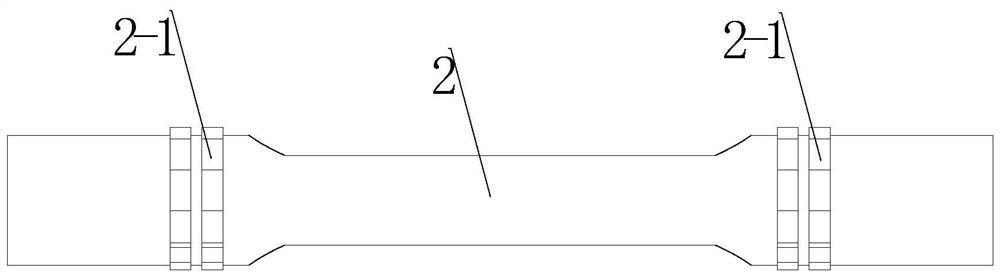

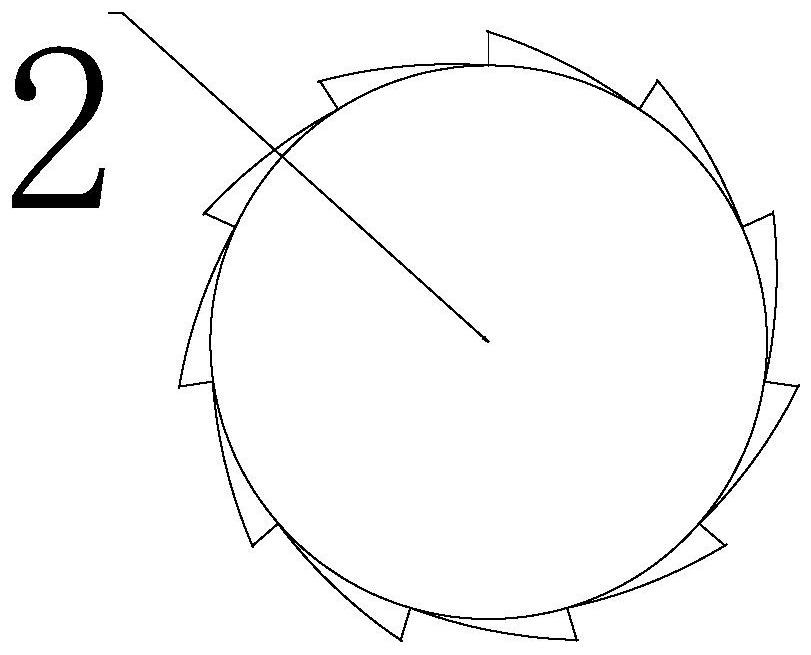

[0030] Example: such as Figure 1-8 As shown, a locomotive anti-rolling torsion bar device torsion bar and rocker arm connection structure, the connection structure includes a bracket 1, a torsion bar 2, a rocker arm 3, a docking device 4, and the torsion bar 2 is arranged sequentially from the middle to both ends The limit snap ring 5, the docking device 4, the bracket 1, the inside of the bracket 1 is provided with a bearing, the torsion bar 2 is installed on the bracket 1 through the rotation of the bearing, the side wall of the docking device 4 and the bracket 1 is fixed by screws, and the limit snap ring 5 is installed on the other side of the docking device 4, and the limit snap ring 5 plays a role in limiting the position of the docking device 4. There are two sets of level adjustment mechanisms 4-1 inside the docking device 4, and one end of the docking device 4 is set on the On the torsion bar 2 , the other end of the docking device 4 is rotatably connected to the roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com