Plastic sheet winding device

A winding device and plastic sheet technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of poor winding quality of plastic sheets, uneven wrinkles, uneven traction of plastic sheets, etc. , to achieve the effect of improving the winding quality, smoothing the folds and uniform traction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

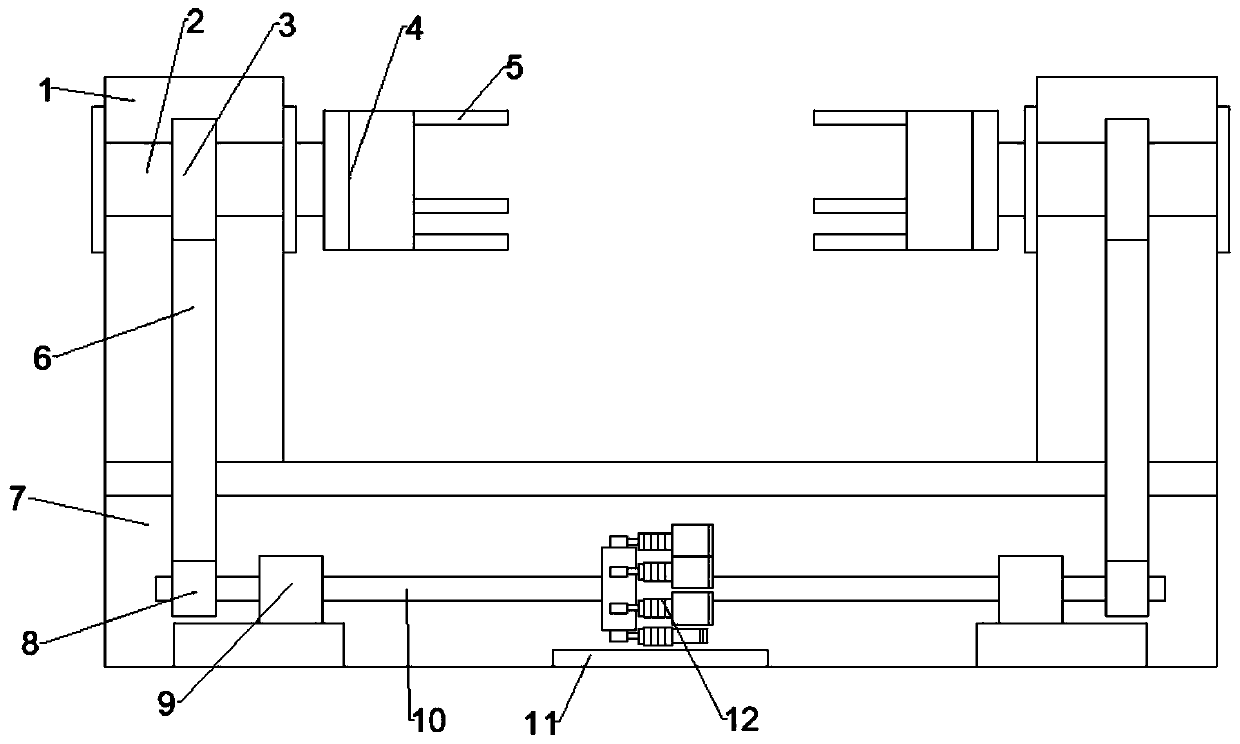

[0023] see figure 1 , in Embodiment 1 of the present invention, a plastic sheet rolling device, which includes: a base 7 and a mounting frame 1, the mounting frame 1 is installed and fixed on the left and right sides of the base 7; A roll assembly, a transmission assembly is installed inside the installation frame 1; a drive assembly 12 is provided inside the base 7, and the middle of the drive assembly 12 passes through the driving shaft 10, and the driving shaft 10 is connected to the transmission assembly;

[0024] Start the driving assembly 12, the driving assembly 12 makes the driving shaft 10 run, and the running driving shaft 10 drives the winding assembly to run through the transmission assembly, and then rolls the plastic sheet.

[0025] Further, the number of winding assemblies is two, and the winding assembly includes a winding main shaft 2, a winding sleeve 4 and a winding fork 5, the lower end of the winding main shaft 2 is connected with the transmission assembly...

Embodiment 2

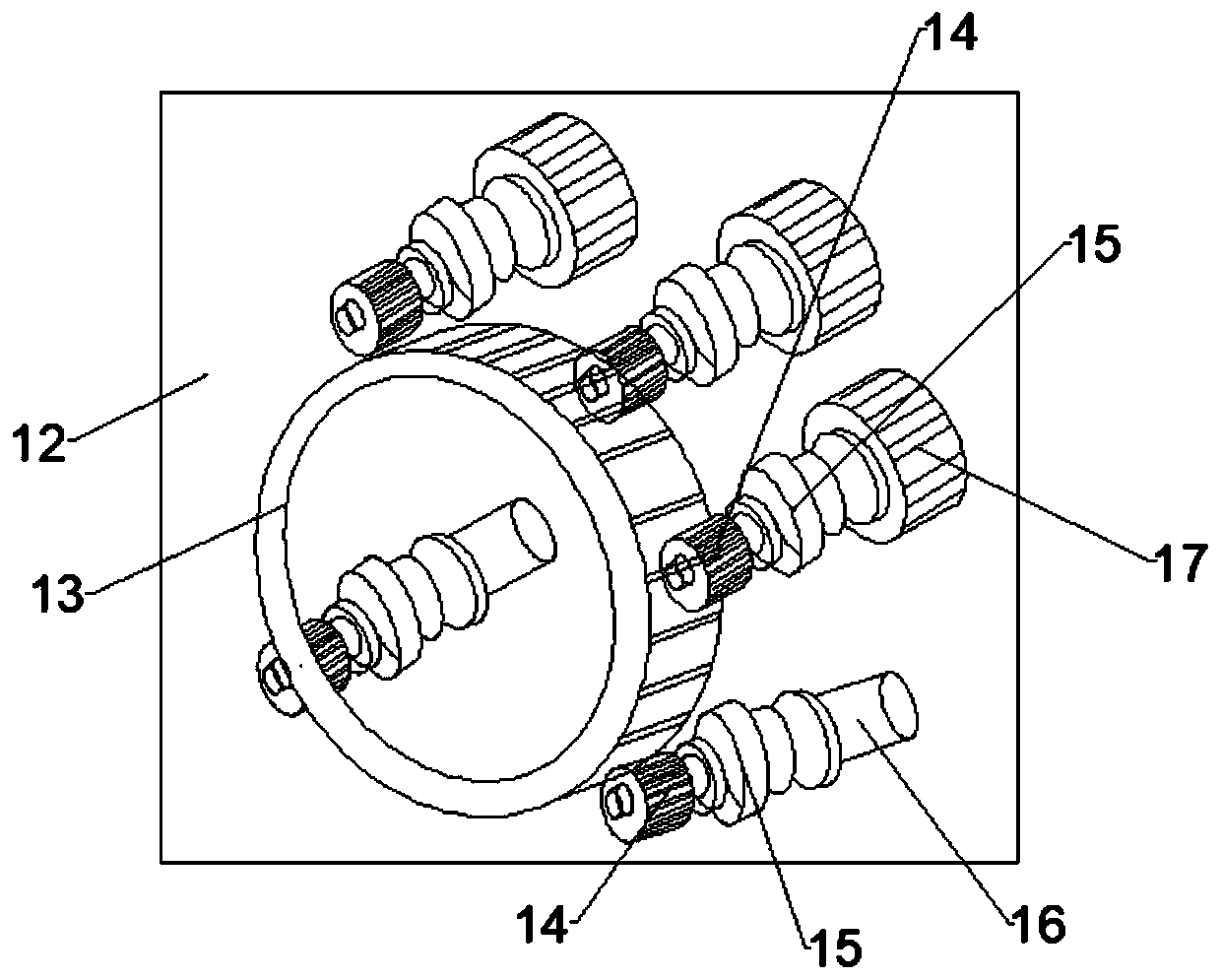

[0030] see figure 2 , further, the drive assembly 12 includes a large gear 13, the output assembly and the torque control assembly are arranged on the edge of the large gear 13; the driving shaft 10 is installed and fixed in the middle of the large gear 13;

[0031] Specifically, the number of the output assemblies is three, and the three output assemblies are distributed on the edge of the bull gear 13 and interlock with the bull gear 13. The output assemblies include a pinion 14, a reduction box 15, and a variable frequency motor 17. The output power of the motor 17 drives the small gear 14 to rotate after being decelerated by the reduction box 15, and then drives the drive shaft 10 fixed inside the middle of the large gear 13 to rotate;

[0032] Specifically, the number of the torque control assembly is two, and the two torque control assemblies are distributed on the edge of the bull gear 13 and interlock with the bull gear 13. The torque control assembly includes a pinio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com