Hydraulic jack with high jacking force

A jack and lift technology, which is applied in the field of hydraulic jacks, can solve the problems of limit seat wear, accelerate deformation and damage speed, reduce the limit effect, etc., and achieve the effect of compact and stable structural connection, avoiding displacement deviation, and avoiding damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

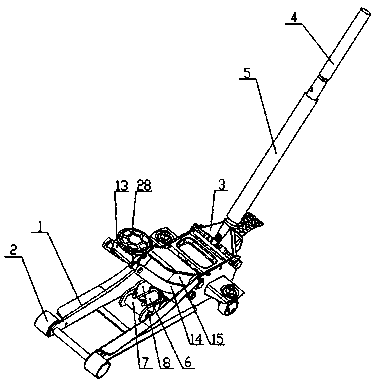

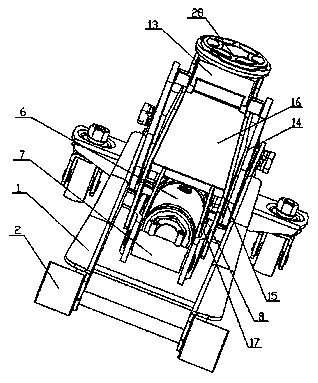

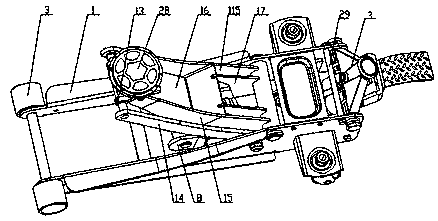

[0046] Such as Figure 1 to Figure 4 It shows an embodiment of an oil hydraulic jack with high lifting force of the present invention, including

[0047] A base mechanism, the base mechanism includes a base composed of two upwardly extending support plates 1, with rollers 2 on the base;

[0048] A handle bar mechanism; the handle bar mechanism includes a handle seat 3 placed between two support plates 1 and a first handle bar 4 and a second handle bar 5 placed on the handle seat 3 and connected to each other;

[0049] A driving mechanism, the driving mechanism includes a hydraulic cylinder 6 arranged on the two support plates, and the hydraulic cylinder 6 is arranged horizontally;

[0050] A lifting mechanism; the lifting mechanism includes a base, a limit shaft group and a lifting seat, the base includes a fixed column 7 placed between two support plates 1, and the extension direction of the fixed column 7 is perpendicular to the extension direction of the support plate 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com