Interface for connecting electric motor to wiring harness, and electric motor

A technology of electric motors and cable harnesses, applied in the field of electric motors, can solve problems such as suboptimal contact safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

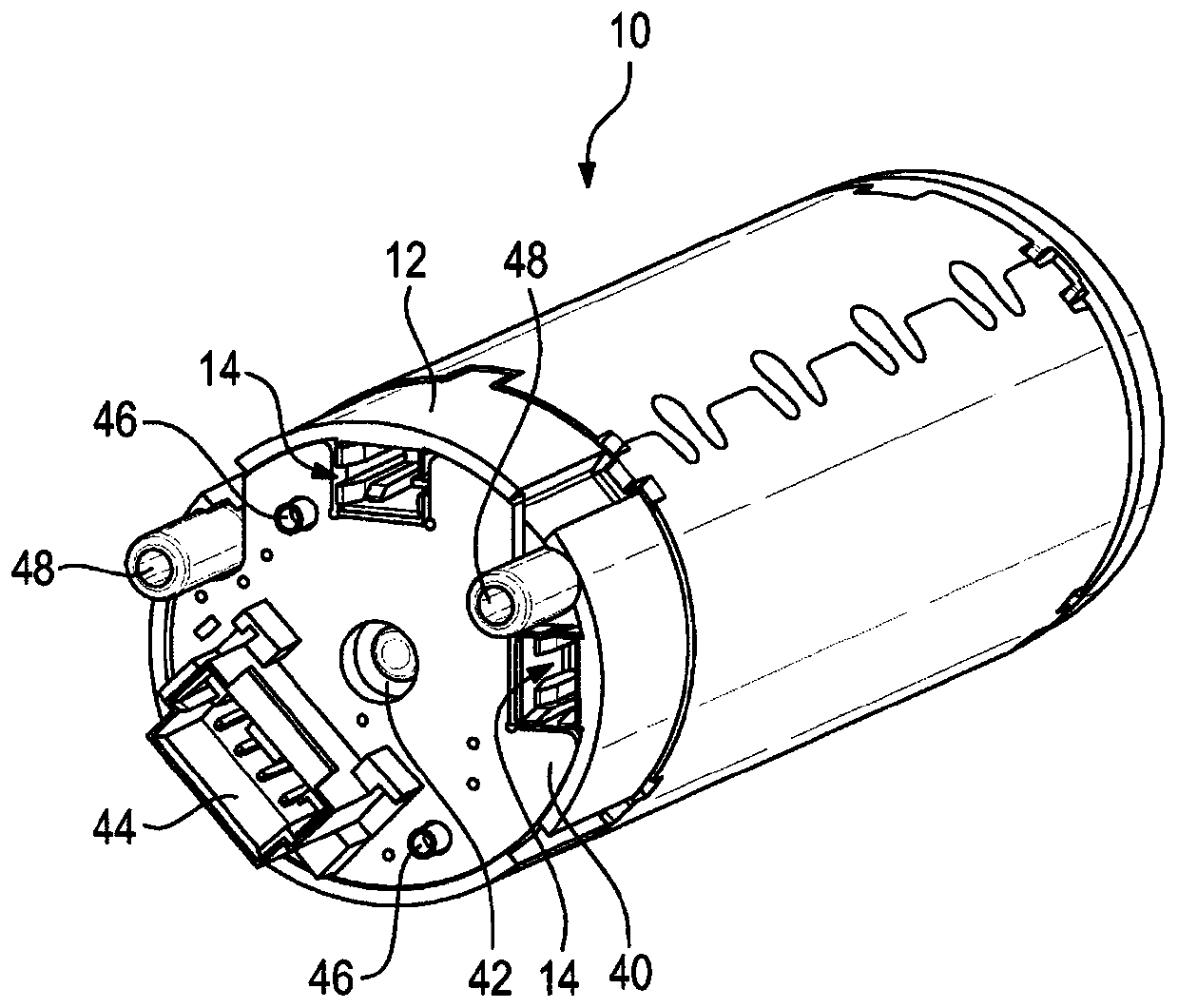

[0020] exist figure 1 An electric motor 10 can be seen in the figure, which is especially designed for use in a servo drive, such as it is used in a motor vehicle. One example is a spindle drive.

[0021] On its side facing away from the output side, the electric motor is provided with connections for connecting the electric motor to a cable harness. The interface is used here to transmit electrical energy for driving the electric motor 10 and to connect the electric motor 10 to a control unit.

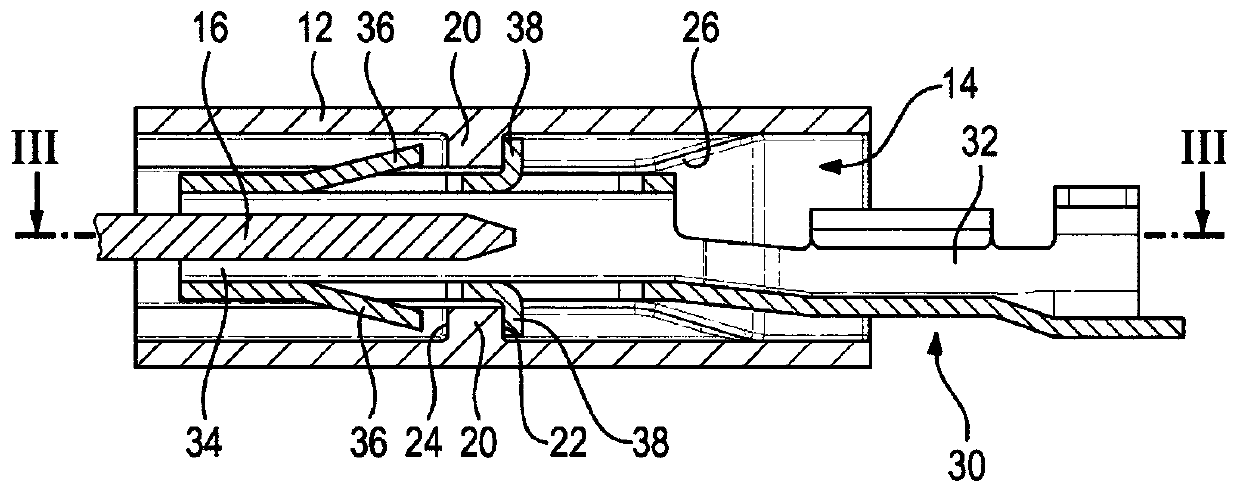

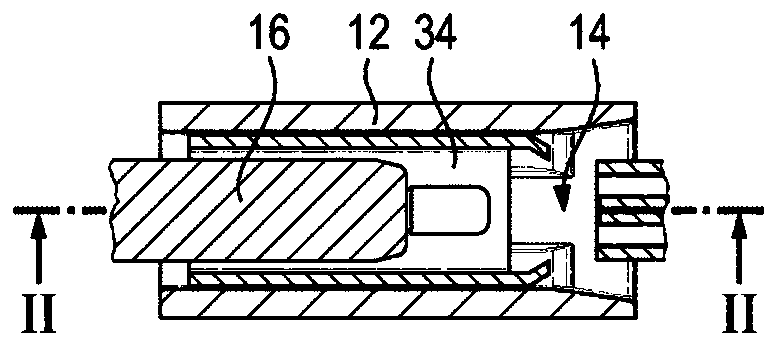

[0022] The interface has a housing 12 which is designed here as a brush holder housing. The plug-in cavity is integrated in the housing 12 (see also figure 2 and 3 ), the plug-in cavity is arranged such that the contact piece 16 of the motor extends into each plug-in cavity 14 . The two contact blades 16 serve to transmit the electric drive power to the electric motor 10 .

[0023] Each plug cavity 14 is provided with a narrowing 20 which has shoulders on opposite sides. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com