A processing equipment for the production of externally balanced thermal expansion valves for qpw5 automobile air conditioners

A thermal expansion valve and processing equipment technology, applied in the field of auto parts processing, can solve the problems of affecting the processing efficiency of the expansion valve, inconvenient driving operation, troublesome loading and unloading of the frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

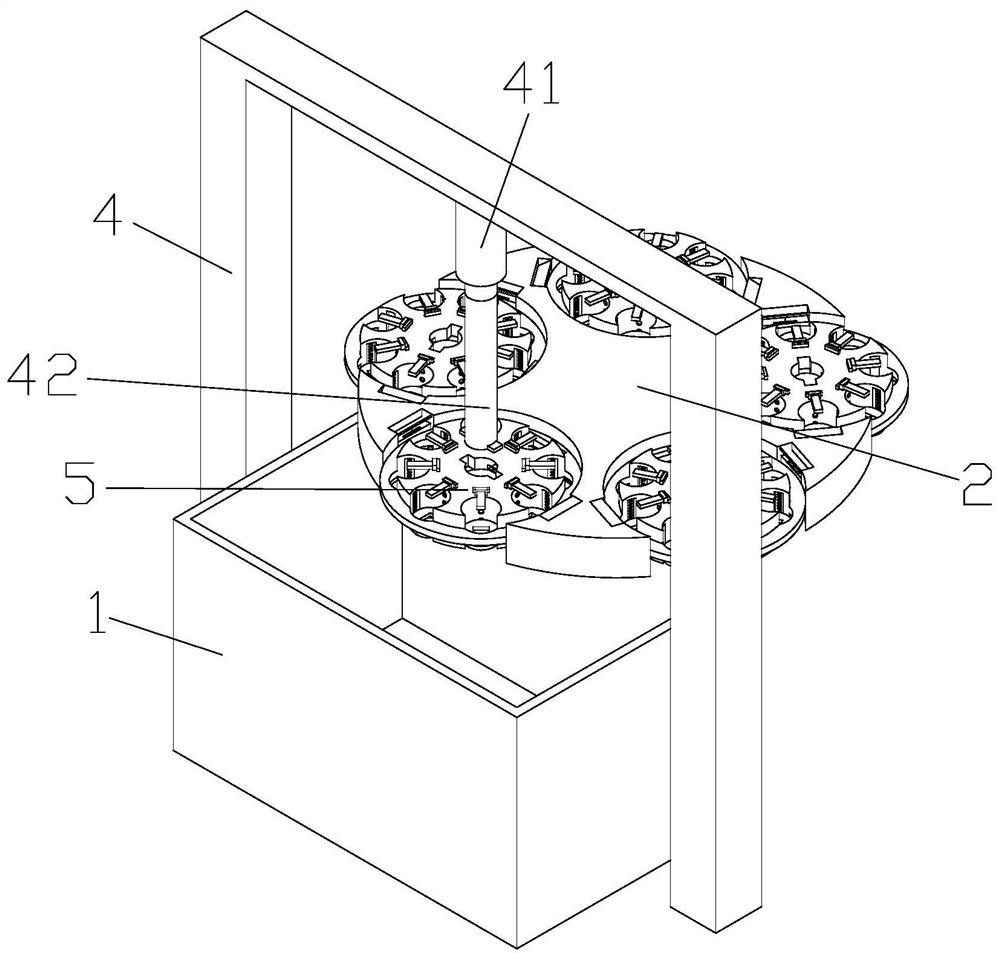

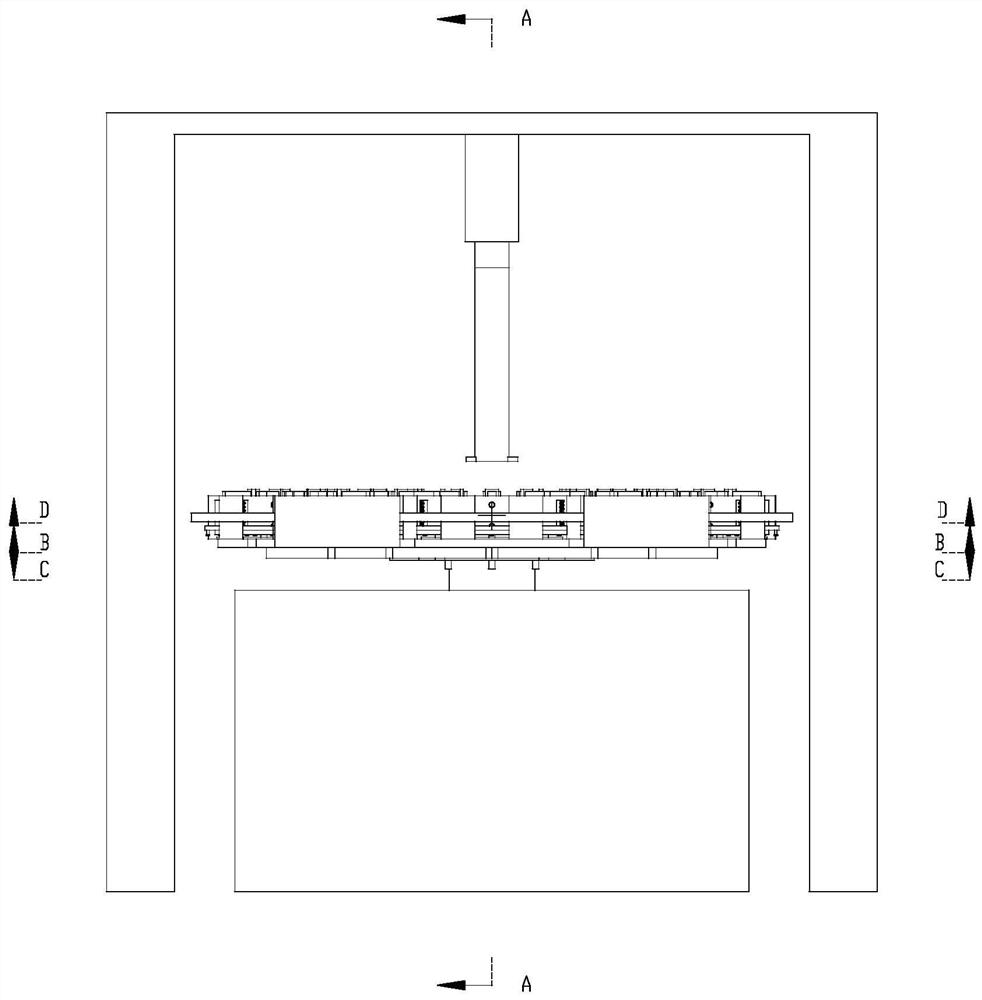

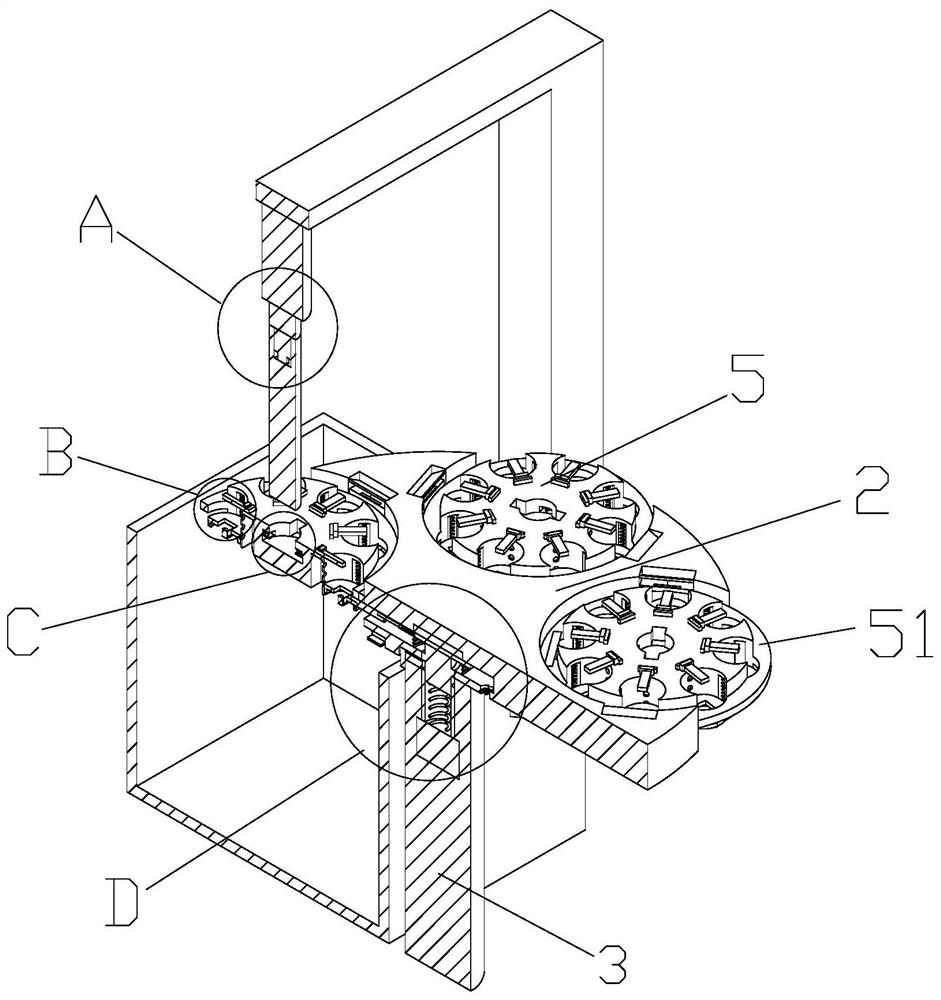

[0033] Such as Figure 1-17 As shown, a processing equipment for producing QPW5 automotive air-conditioning externally balanced thermal expansion valves, including an acid pool 1, a support column 3 located on one side of the acid pool 1, a support column located on the support column 3 The turntable 2, the loading tray 5 arranged on the turntable 2 and the installation frame 4 arranged above the acid pool 1, the installation frame 4 is provided with a hydraulic cylinder 41, and the piston rod of the hydraulic cylinder 41 A push rod 42 is provided, and the support column 3 is provided with a first drive motor 31 for driving the rotation of the turntable 2, and the turntable 2 is provided with a plurality of first channels matched with the loading tray 5. Cavity, the piston rod of the hydraulic cylinder 41 is provided with a second drive motor 421 for driving the push rod 42 to rotate, and the loading tray 5 is provided with a first connecting groove matched with the push rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com