Square tube buckle

A flat plate and pin technology, which is applied to the connection parts of formwork/formwork/work frame, the on-site preparation of building components, and construction, etc. The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

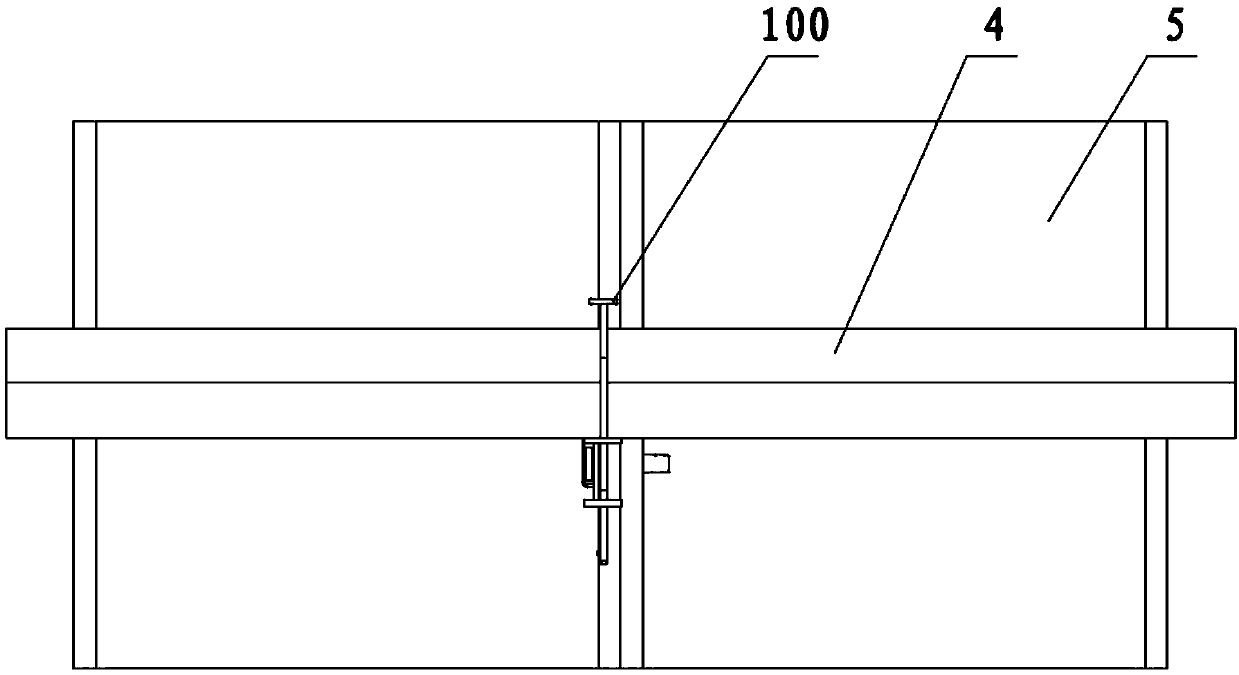

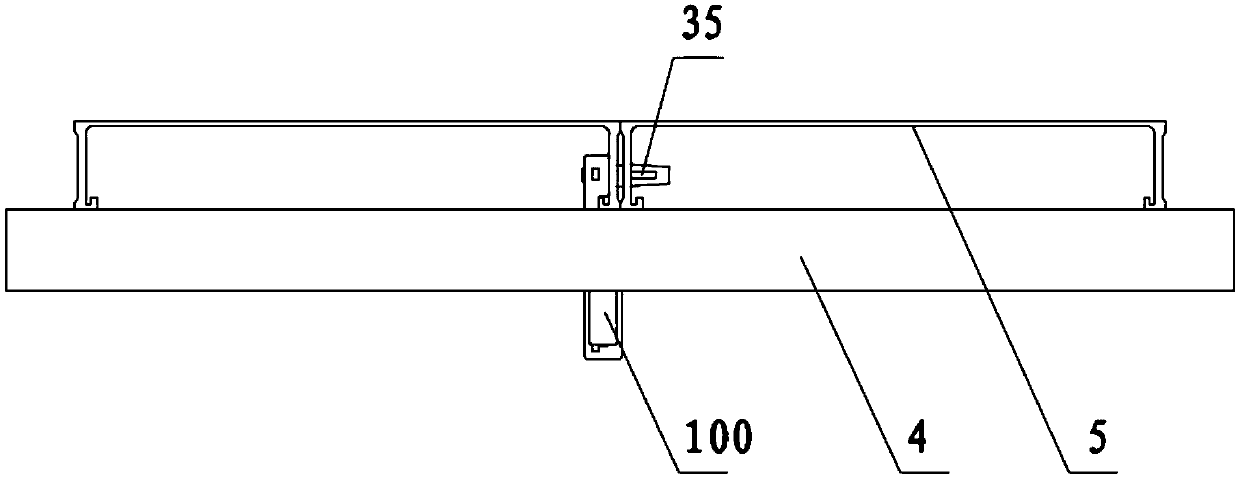

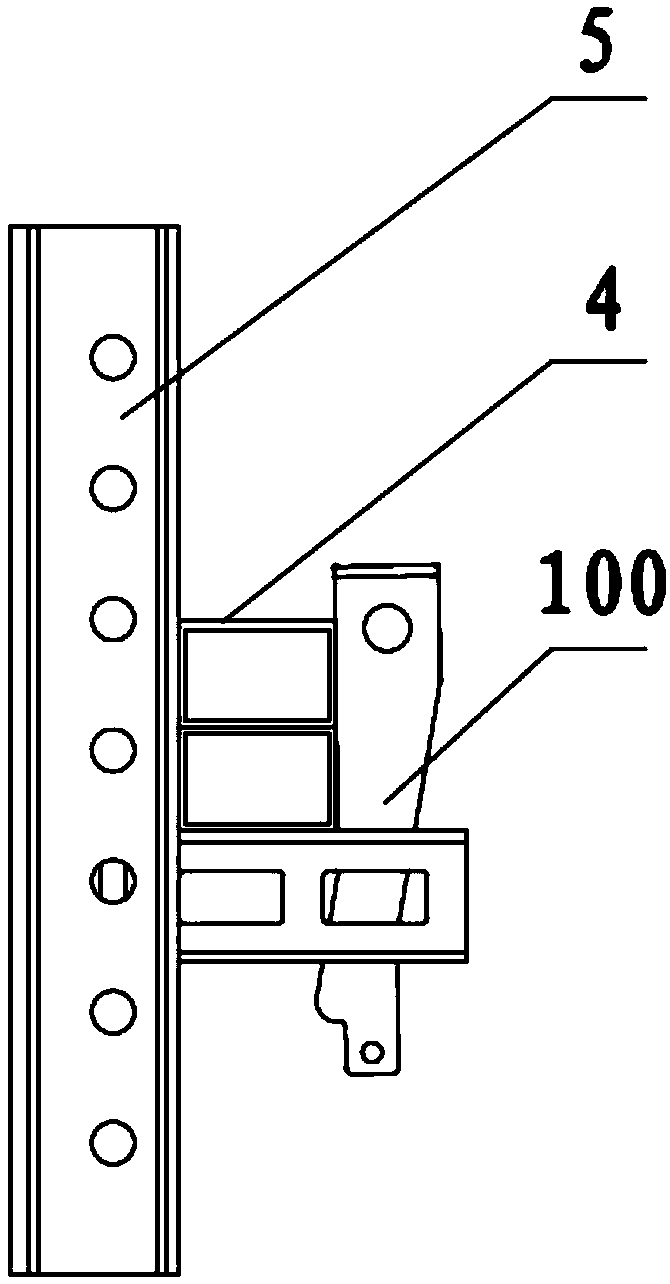

[0039] See attached Figure 1-11 , a square button 100, including a main seat 1, a pin assembly 3 and an insert 2; A flat plate 12 and a second flat plate 13; the seat vertical plate 11 is provided with a pin hole 112 passing through it, and the pin assembly 3 is inserted in the pin hole 112; one end of the first flat plate 12 away from the pin assembly 3 is provided with Through the first insertion hole (not shown); the position of the second seat plate 13 facing the first insertion hole (not shown) is provided with a second insertion hole 131 passing through the second seat plate 13 The insert 2 passes through the first insert hole (not shown) and the second insert hole 131 at the same time; the pin 35 includes a connected support plate 21 and a clamping plate 22; One side is the first clamping surface 221, and the first clamping connection is a plane; the side opposite to the first clamping connection on the clamping plate 22 is the second clamping surface 222, and the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com