Metal stress corrosion image testing method

A technology of image testing and metal stress, which is applied in testing wear resistance, elastic testing, and testing material strength by applying a stable bending force, and can solve problems such as inability to monitor local strain evolution laws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

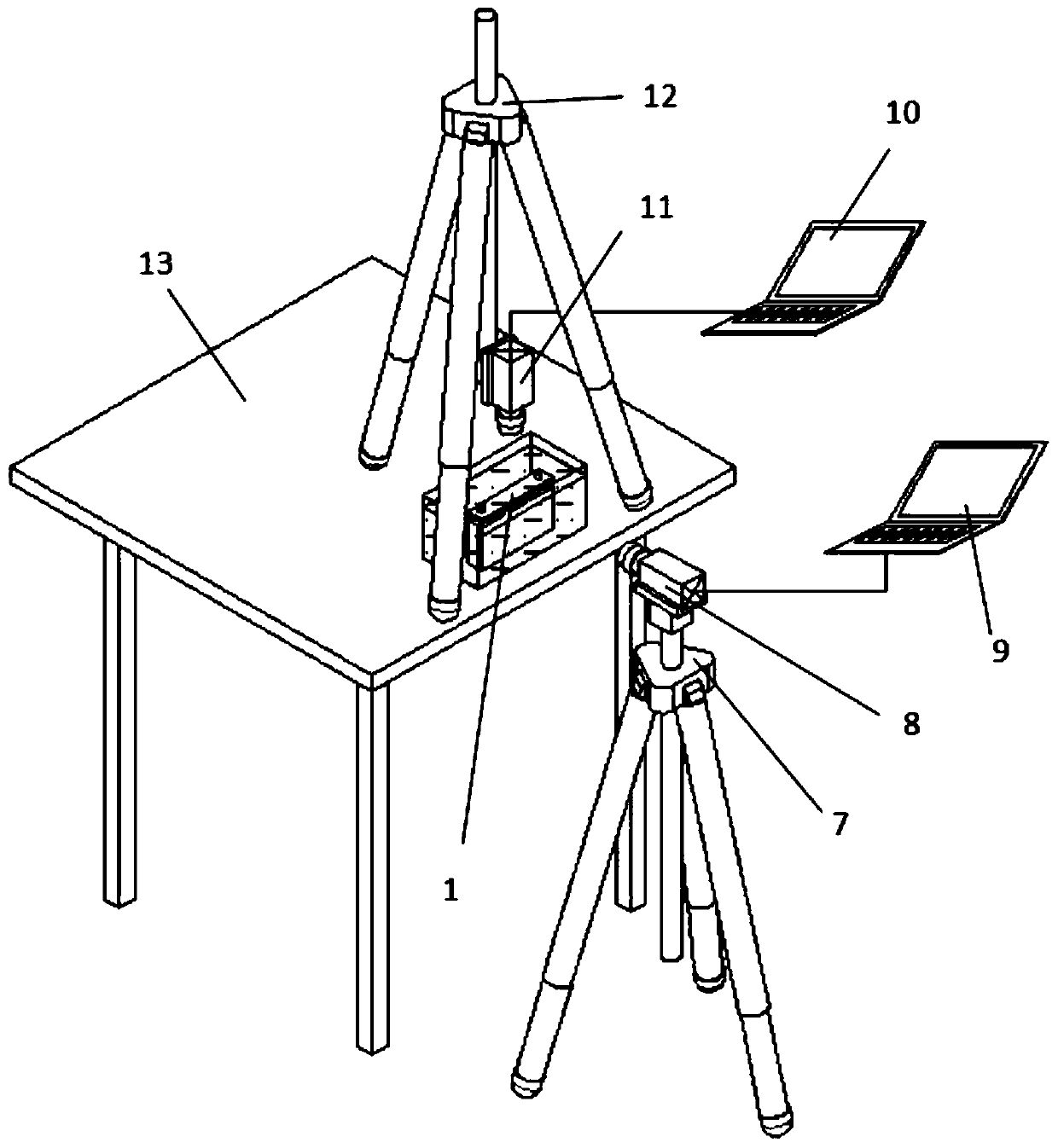

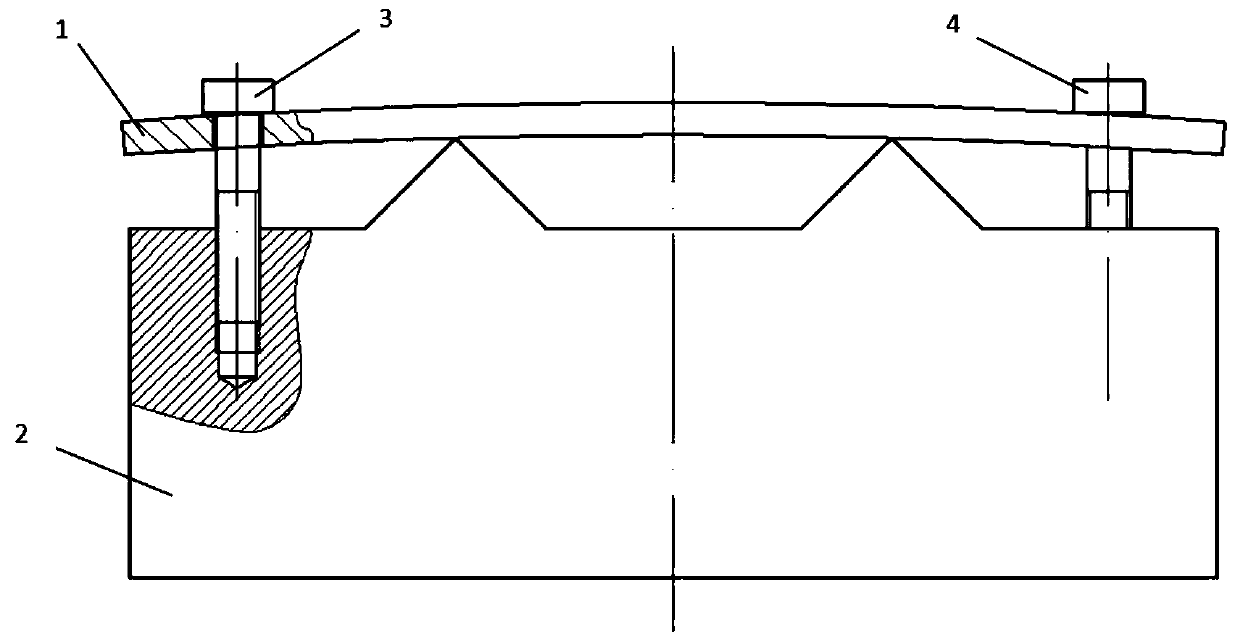

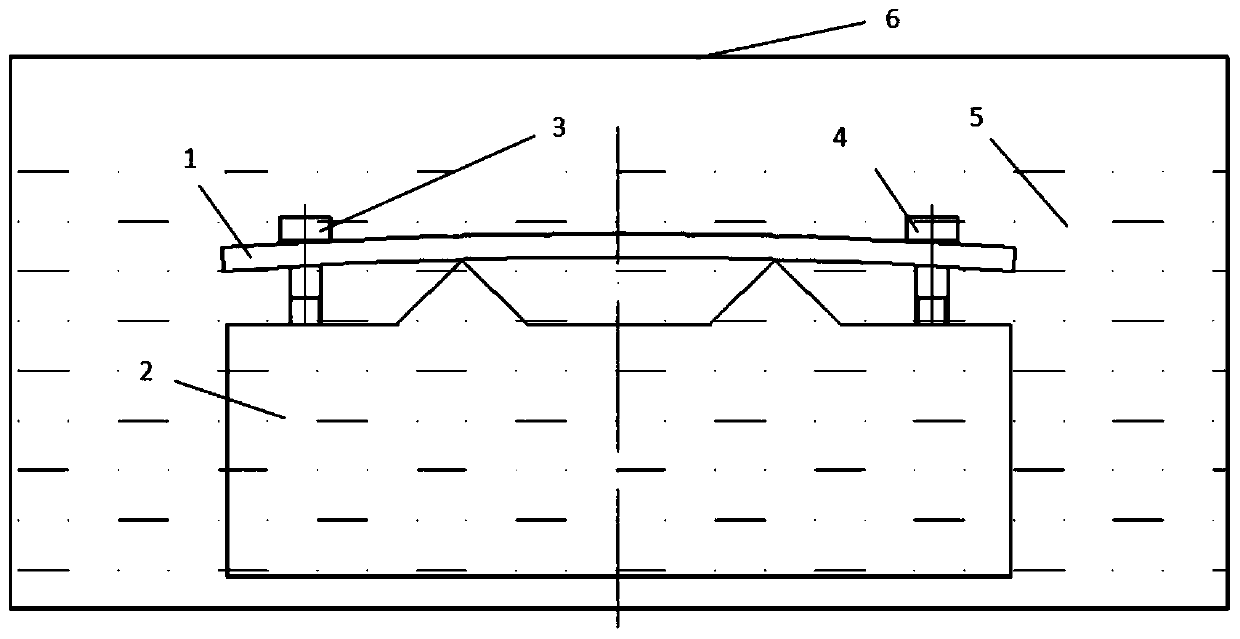

[0024] Such as figure 1 As shown, the metal bending stress corrosion image test experimental device mainly includes: metal sample 1, bending stress loading fixture 2, first hexagon socket bolt 3, second socket bolt 4, corrosion solution 5, rectangular parallelepiped glass container 6, second Support 7, the second CCD camera 8, the second computer 9, the first computer 10, the first CCD camera 11, the first support 12, the experiment table 13 etc., the concrete experiment process is as follows:

[0025] 1. Process the metal sample into a standard style that can be installed and fixed by the stress loading fixture, monitor the upper surface (the area where the maximum elastic tensile stress is located after the bending stress of the metal sample is loaded), polish and corrode the metallographic structure, and monitor the spray spot treatment on the side;

[0026] 2. Bui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com