Insulating insulator cradle front-end fixing ring position adjustable device and working method thereof

A technology of fixing ring and bottle holder, applied in the direction of overhead line/cable equipment, etc., can solve the problems of difficulty in disassembling and assembling insulators, high labor intensity, and the insulator cannot be supported by the bottle holder, so as to improve the replacement work efficiency and reduce the labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

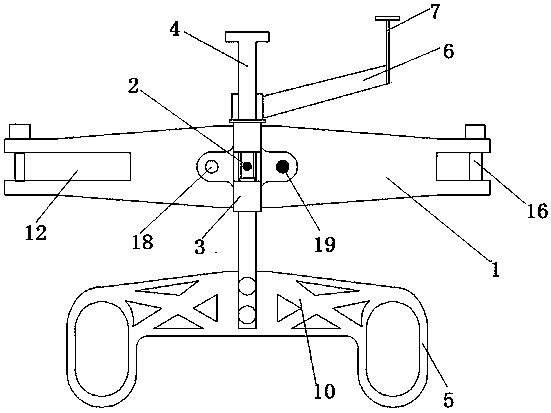

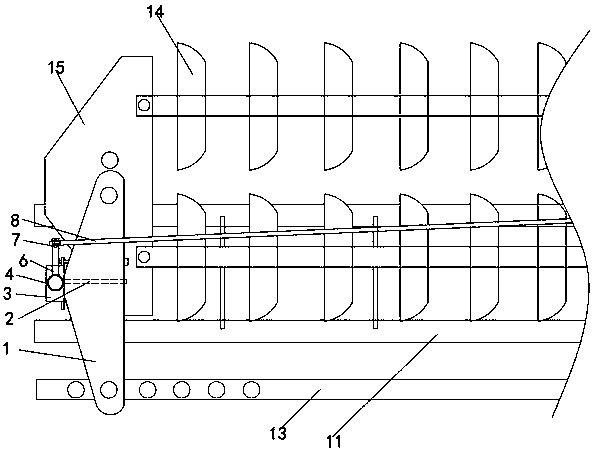

[0017] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the drawings, and detailed descriptions are made as follows.

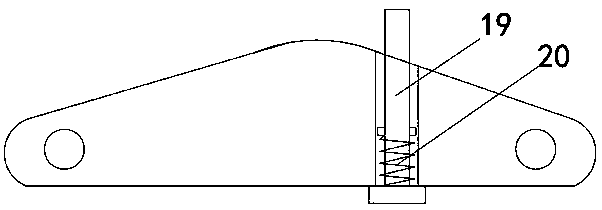

[0018] Such as Figure 1~3 As shown, the device for adjusting the position of the fixed ring at the front end of the insulated bottle holder includes a large knife clamp 1. The middle of the front end of the large knife clamp is connected with a sleeve 3 through a rotating shaft 2 that penetrates back and forth, and a screw 4 is screwed through the top of the sleeve. Adjust the vertical height of the fixing ring 5 at the lower end of the screw. The proximal end of the screw is fixedly provided with an adjusting knob 6 fixedly connected to the top of the outer end of the adjusting knob. The adjusting ring 7 is fixedly attached to the top of the outer end of the adjusting screw. Realize adjustment.

[0019] In the embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com