Method for replacing journal main body sleeve

A replacement method and main body technology, which is applied in the field of mechanical processing, can solve the problems of high material waste rate and low efficiency, and achieve the effects of shortening the replacement cycle, prolonging the service life and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

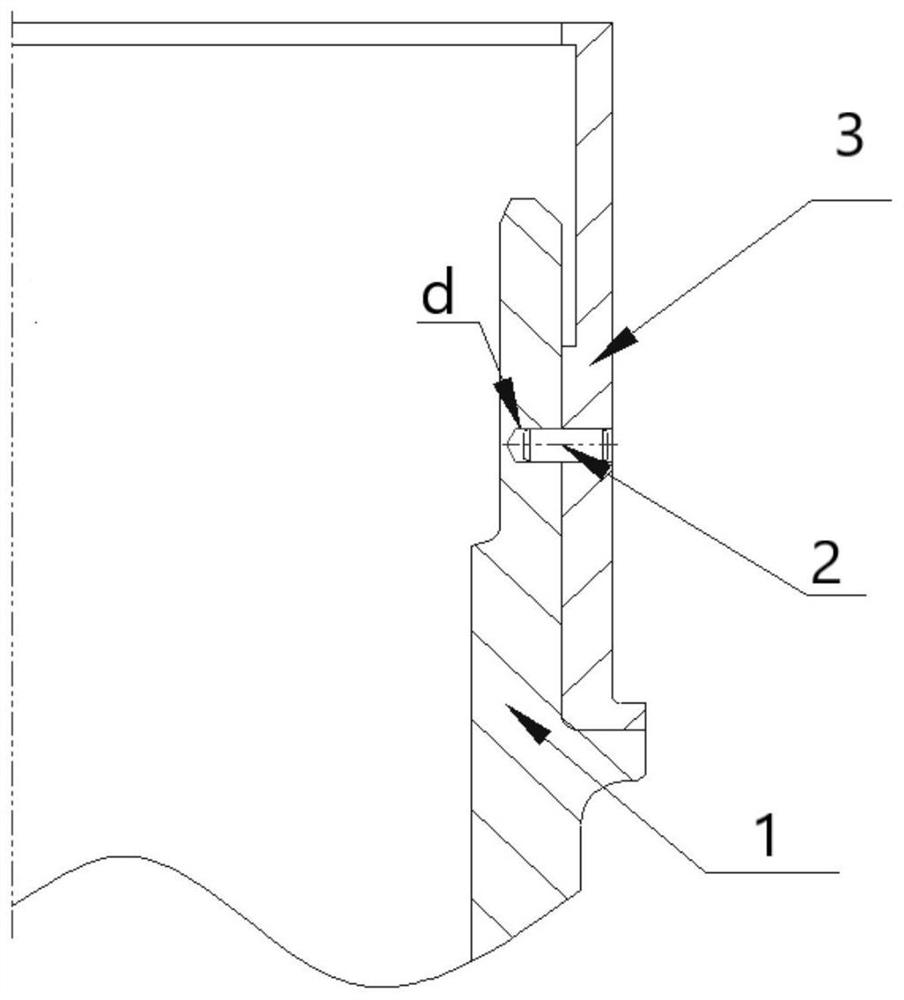

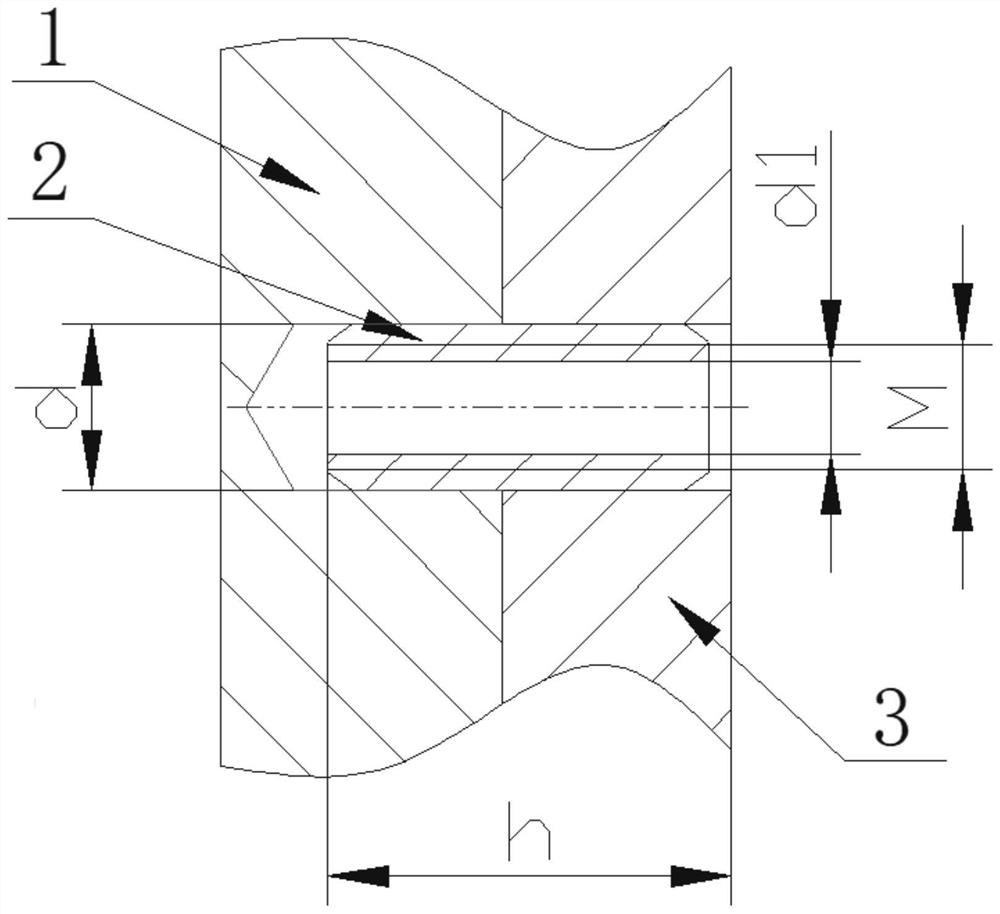

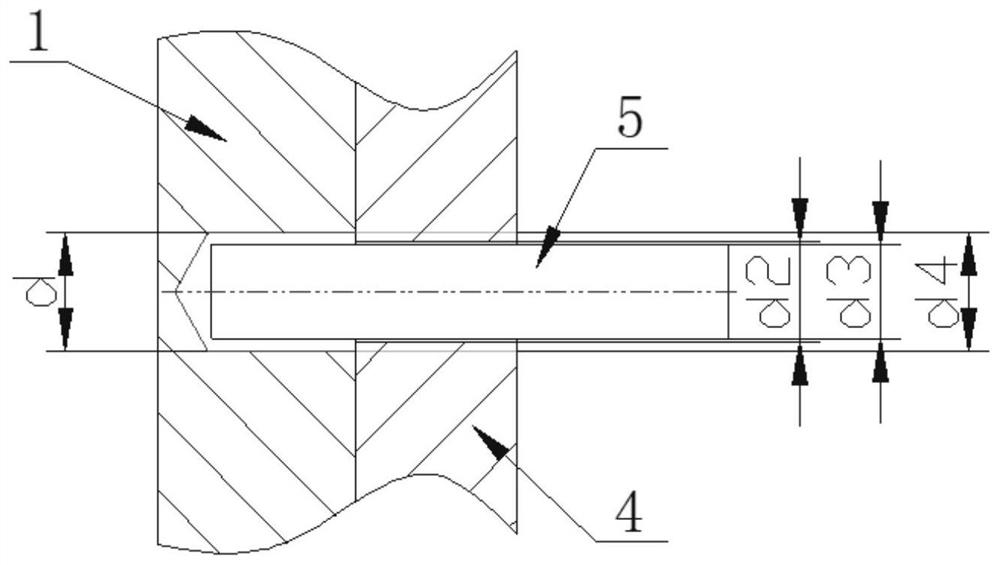

[0032] The present invention will be described in further detail below with reference to the accompanying drawings.

[0033] like figure 2 , image 3 As shown, a method for replacing a journal main body sleeve provided by the present invention includes the following steps:

[0034] Step 1, remove the stop pin through the pin puller;

[0035] Step 2, remove the sleeve on the main body of the journal;

[0036] Step 3, measure the position of the blind hole for the pin connection on the main body of the journal;

[0037] Step 4: According to the measured position, a positioning hole is processed on the new sleeve to be replaced, with a diameter of d2; the purpose of processing the positioning hole is to ensure that there is no interference when the lever dial indicator is used for alignment.

[0038] Step 5, install the new sleeve to be replaced on the journal main body, and the position of the positioning hole is within the diameter range of the pin coupling blind hole on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com