A kind of furniture board with replaceable surface wear-resistant layer

A wear-resistant layer and plate technology, which can be applied to home appliances, furniture parts, manufacturing tools, etc., can solve the problems of difficult replacement of the wear-resistant layer, and achieve the effects of firm fixation, reduced risk of detachment, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

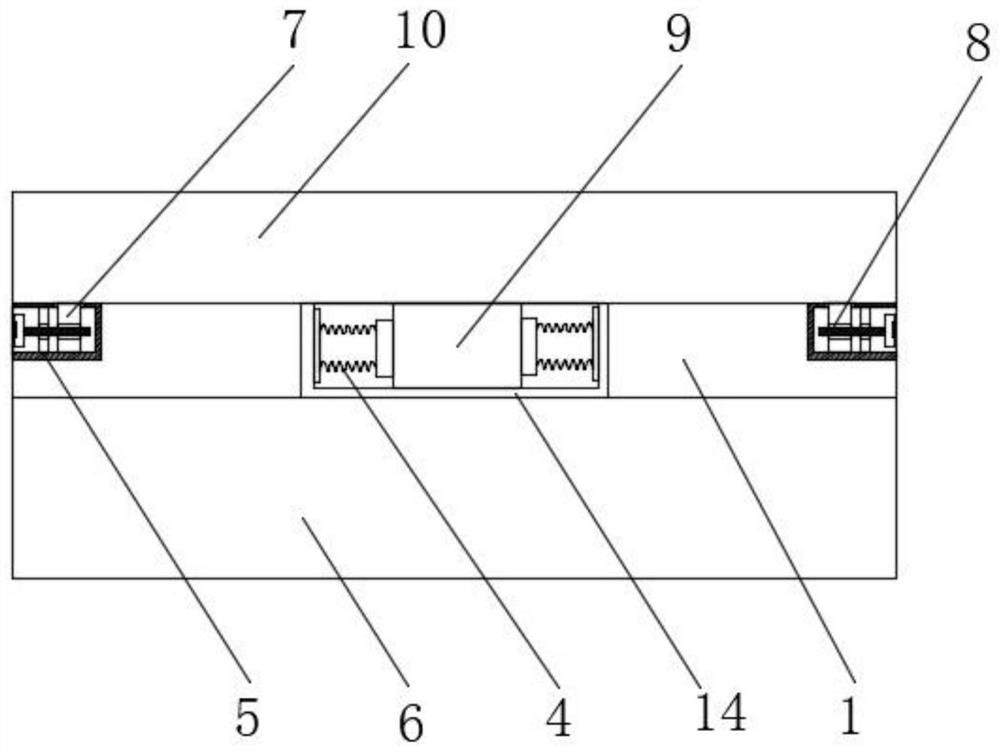

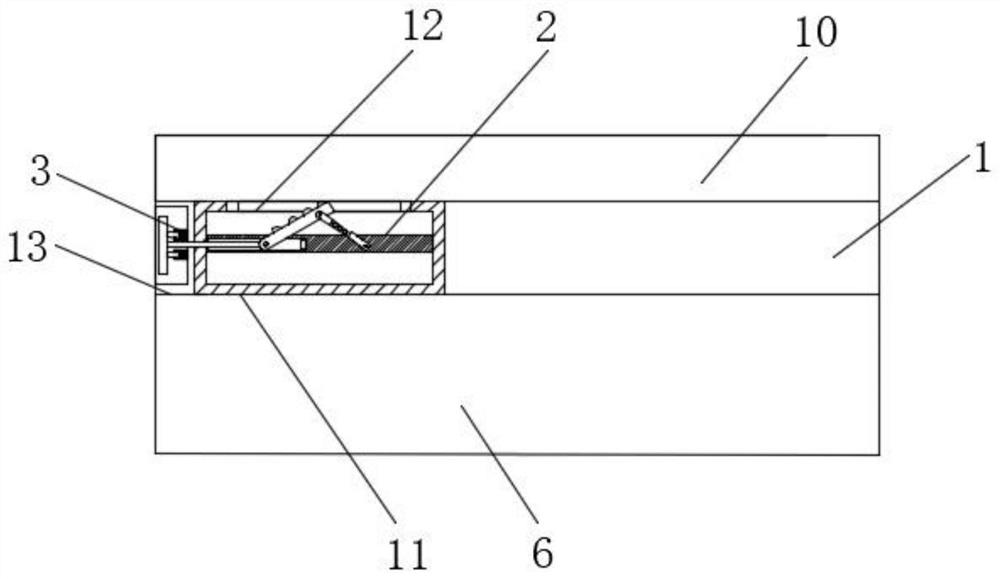

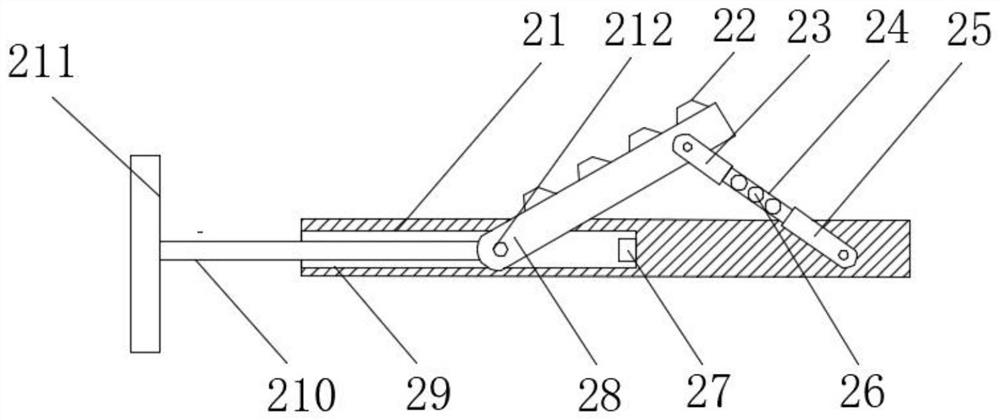

[0031] like Figure 1-7 As shown, the embodiment of the present invention provides a furniture board with a replaceable surface wear-resistant layer, comprising a board connection layer 1, a board stress layer 6 is fixedly connected to the lower end of the board connection layer 1, and a groove is opened on the upper surface of the board connection layer 1 14. Two limiting devices 4 are fixedly installed on the side walls of the groove 14, two fixing devices 5 are fixedly installed inside the plate connection layer 1, and the plate wear layer 10 and the plate wear layer 10 are fixedly installed at the upper end of the plate connection layer 1. A connecting plate 9 and a fixing column 7 are fixedly installed at the lower end. The side wall of the fixing column 7 is provided with a threaded hole 8. A push-pull device 2 is fixedly installed on the inner side wall, a movable slot 12 is opened on the top of the storage box 11 , and two buffer devices 3 are fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com