Roller press with powder concentration function

A technology of roller press and powder, applied in the field of roller press, can solve the problems of dispersion to both sides of the roller and poor rolling effect, so as to improve the effect of aggregation, improve the efficiency of powder forming, and improve the efficiency of rolling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

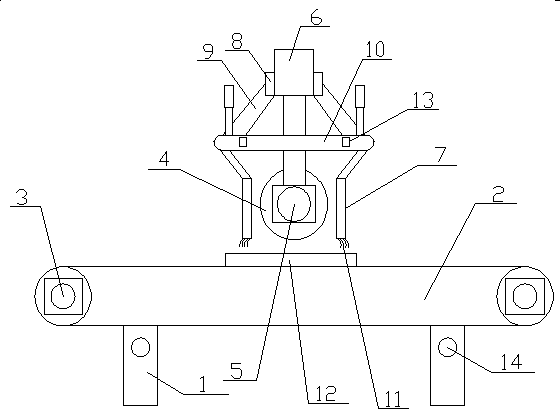

[0012] Such as figure 1 As shown, the present embodiment provides a roller press with a powder concentration function, including a frame 1, a conveyor belt 2 is arranged on the frame 1, and a transmission device 3 is provided at both ends of the conveyor belt 2. The device 3 drives the conveyor belt 2 to work, the middle section of the conveyor belt 2 is provided with a pressure roller 4, and the powder is rolled by the pressure roller 4, and the two ends of the pressure roller 4 are provided with extrusion motors 5, and the extrusion motor 5 The upper end is provided with a lifting cylinder 6, which drives the pressure roller 4 and the extrusion motor 5 to rise and fall as a whole. The t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap