Quick glue dispensing device for circuit board production

A dispensing device and circuit board technology, which is applied to the surface coating liquid device, printed circuit, printed circuit manufacturing, etc., can solve the problems of low service life of the dispensing head, affect work efficiency, replacement, etc., and achieve the adjustment coverage Wide range, improved service life, and improved dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

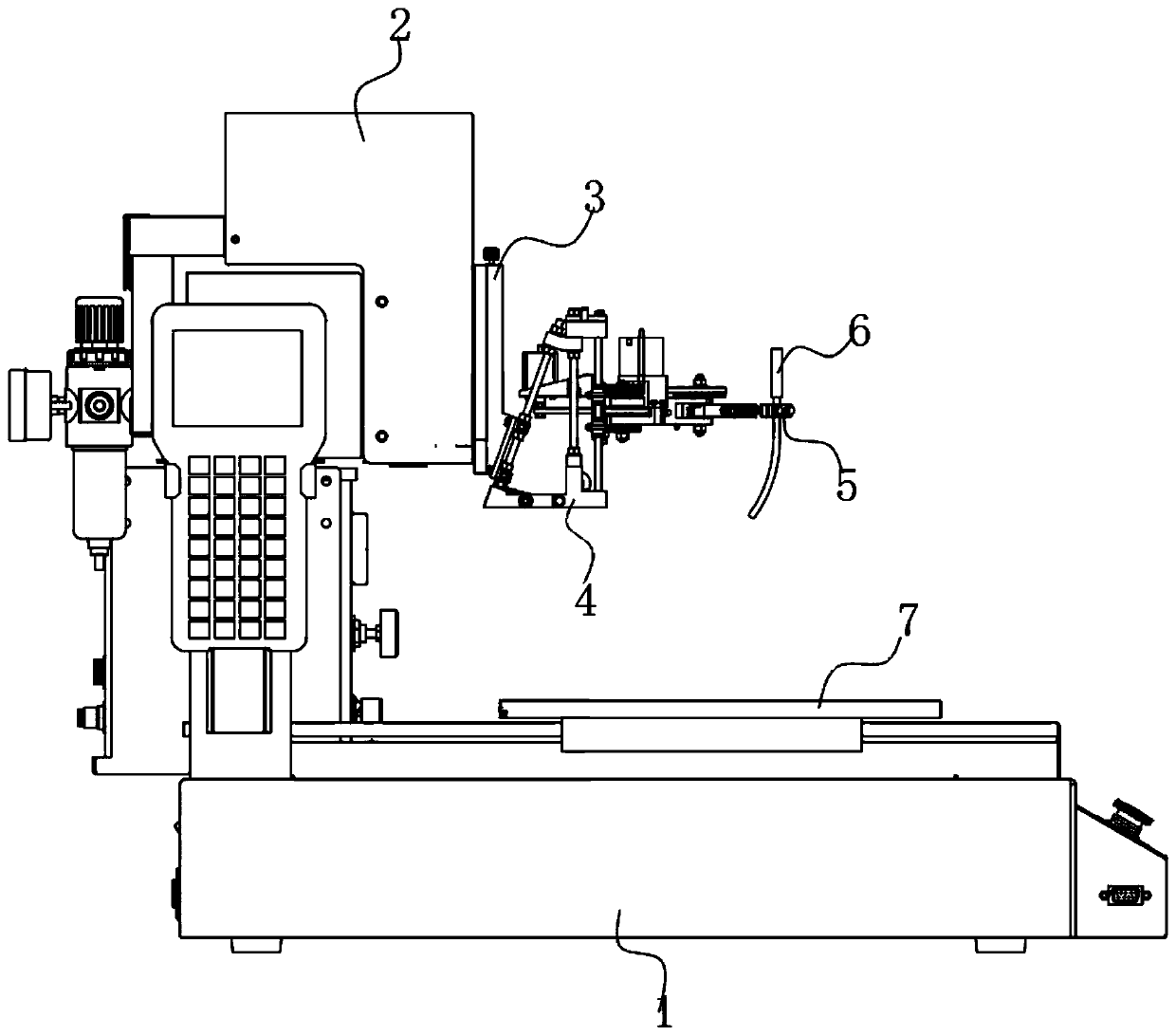

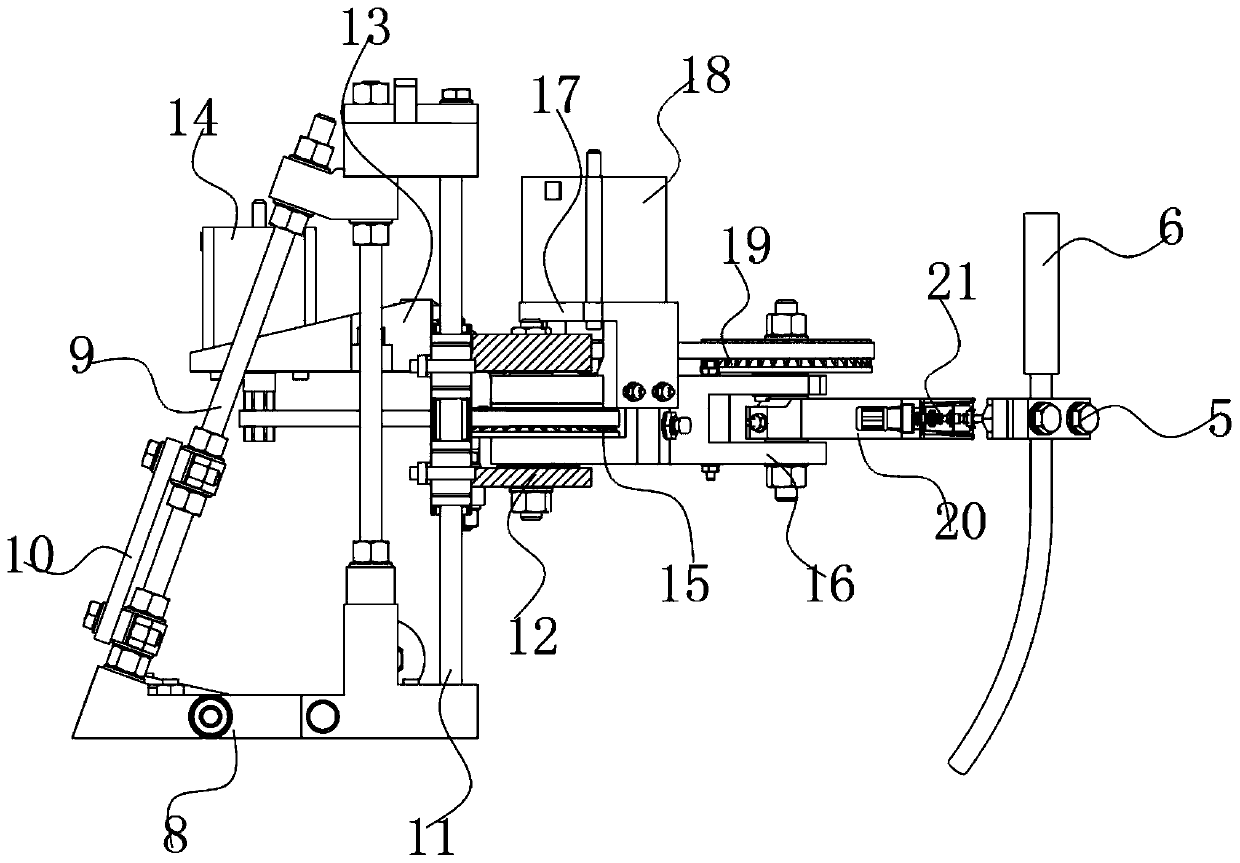

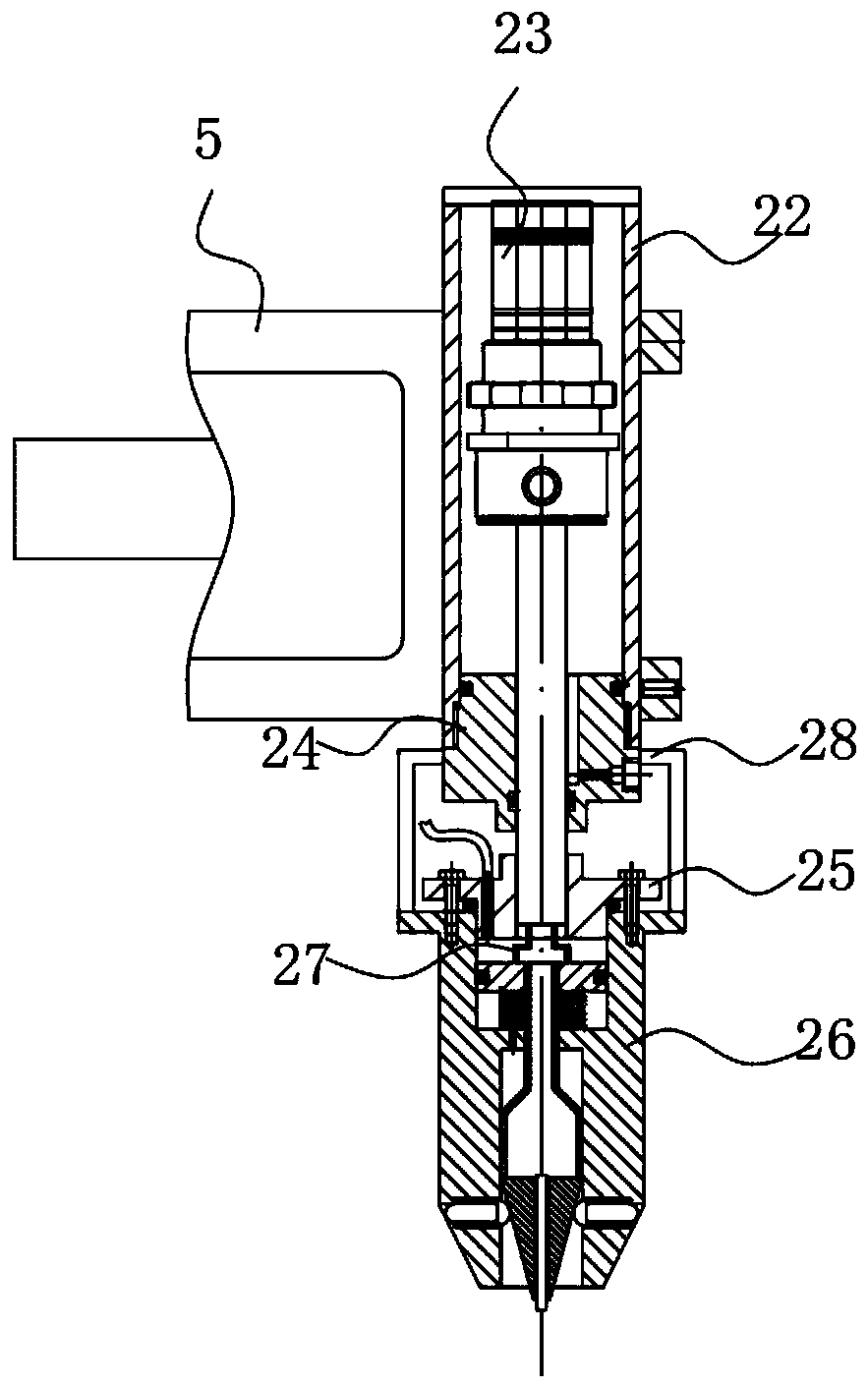

[0024] see Figure 1~4 , in an embodiment of the present invention, a rapid dispensing device for circuit board production, including a main console 1, a driving arm 2, a position and angle adjustment assembly 4, a clamping seat 5, and a dispensing assembly 6, the main control The left end of the table is provided with a driving arm 2, and the driving arm 2 is connected with a position and angle adjustment assembly 4 by using a mounting seat 3. The position and angle adjustment assembly 4 can adjust the clamping seat 5 arranged at its output end, thereby changing the clamping position. The position of the holding seat 5 and the angle between it and the horizontal plane, the dispensing assembly 6 is fixed on the holding seat 5, and the circuit board placement frame 7 is also fixed on the main console 1, so as to place the circuit board.

[0025] In this embodiment, the position and angle adjustment assembly 4 includes a base 8, a fixing frame 11, a primary adjustment assembly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com