A magnetic puller

A material puller and magnetic technology, which is applied in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of large footprint, low economy, large investment, etc., and achieve long overall life and magnetic Strong suction, not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

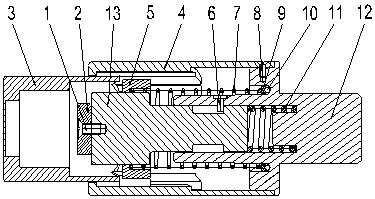

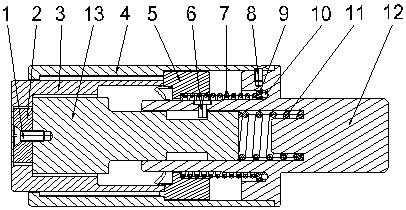

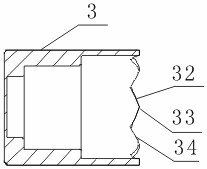

[0031] Figure 1-2 Among them, the fixed strong magnet of slide shaft 13 front ends is installed in the body hole, and spring 11 is arranged at the bottom of the hole, and is fixed in the body hole by three pins 6 of circumferential distribution, and can move axially. There are 4 protruding keys 2 31 on the right end outer circle of shield 3, cooperate with the groove of sleeve 4 inwalls, can move along its axial direction, distance 45 millimeters. There are 8 evenly distributed annular teeth on the right end surface of the shield 3 . There are 4 unreasonable straight grooves on the inner wall of the sleeve 4, which cooperate with the convex key 2 31 on the shield 3, and the ribs 43 positioned on the inner wall of the sleeve 4 are formed between two adjacent straight grooves, and each rib 43 end surface has 2 a helical tooth. The toothed wheel 5 is hollow and is set on the sliding shaft 13. There are 4 protruding keys on the outer circle which match with the straight groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com