Assembly device and method of steel wire screw sleeve

A wire screw sleeve and assembly device technology, applied in the field of mechanical processing, can solve problems such as low efficiency, prone to tooth jumping, and low pass rate of manual installation, so as to achieve the effects of high efficiency in the working process, improvement of reliability, and improvement of installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below.

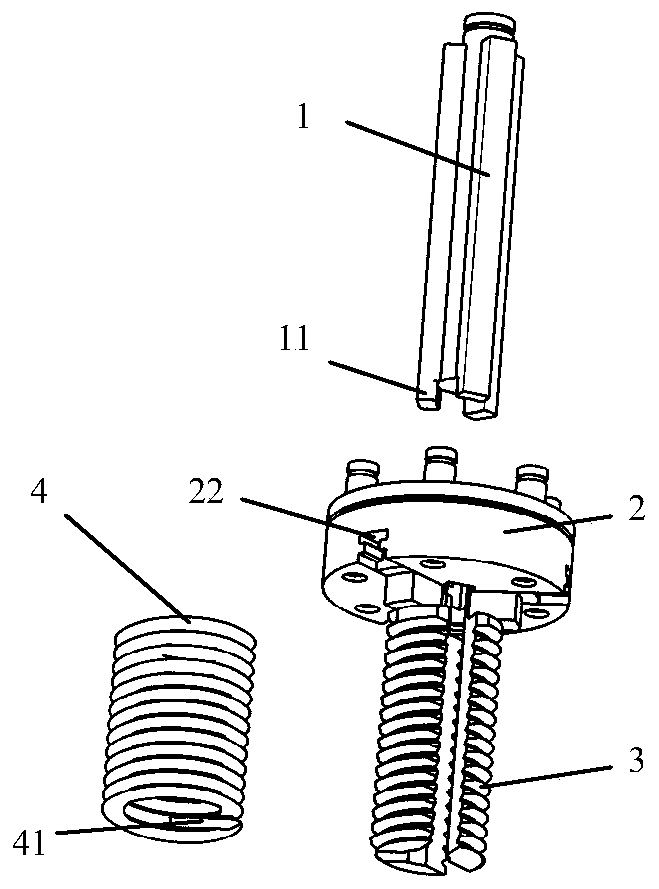

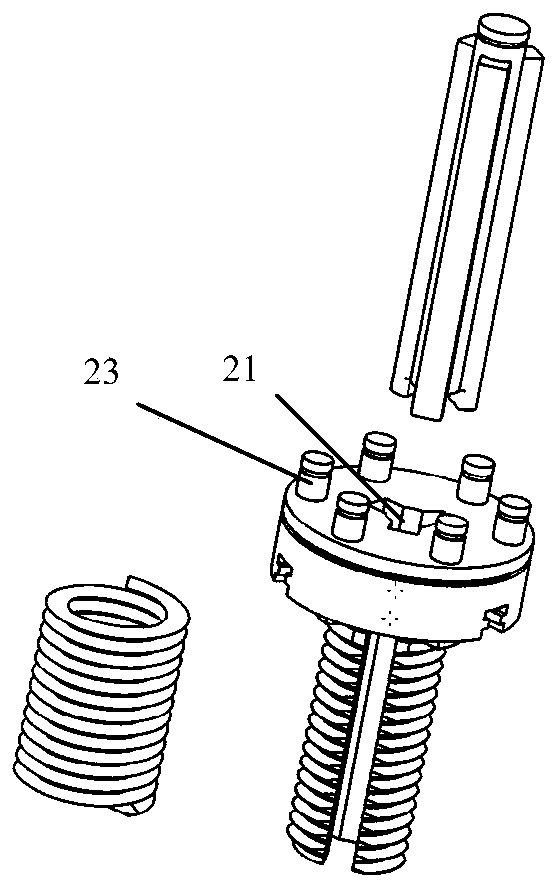

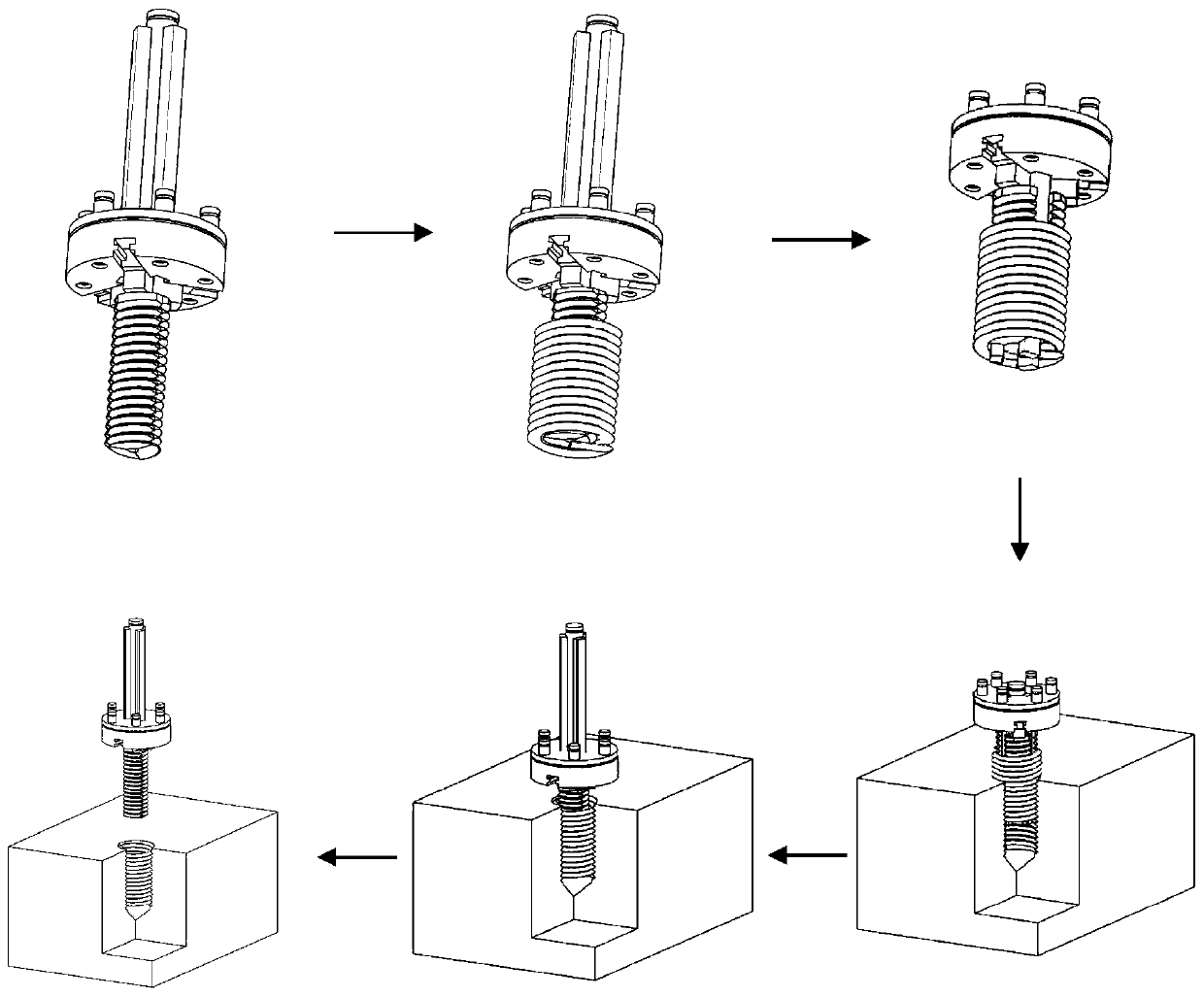

[0023] Such as figure 1 and figure 2 As shown, an assembly device for a wire thread insert provided by the present invention includes a screw core 1, a chuck 2 and a slide screw 3, and 4 in the figure is the installed wire thread insert. The chuck 2 is provided with a screw core track 21 for installing the screw core 1 and a slide screw track 22 for installing the slide screw 3 . The chuck 2 is connected to the tightening device through the quick-change joint 23 and can be quickly replaced. The chuck 2 rotates forward or reverse and axially reciprocates along its central axis according to a given speed, torque, and angle, and can be driven to be installed on the The three sliding screws 3 on it rotate or translate together with the screw core 1 .

[0024] The three sliding scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com