Cup stand for vehicle

A technology for cup holders and vehicles, which is applied to vehicle parts, special positions of vehicles, transportation and packaging, etc. It can solve problems such as liquid spillage, abnormal noise, and mutual collision between cups and cup holders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

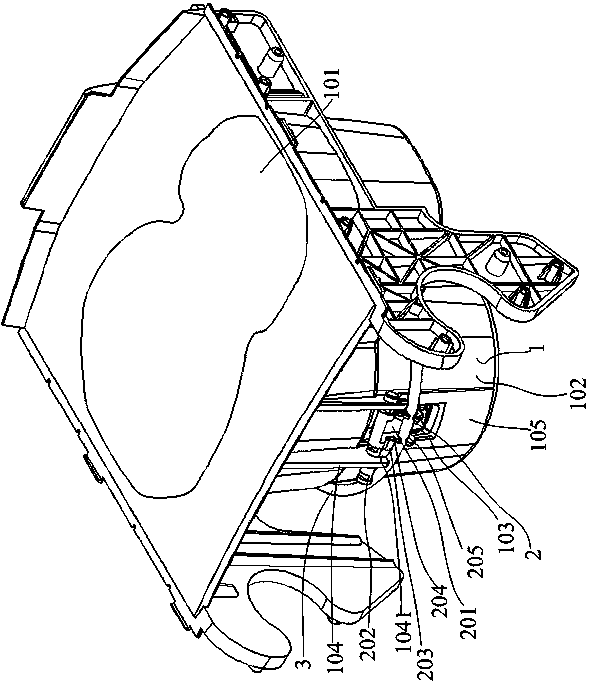

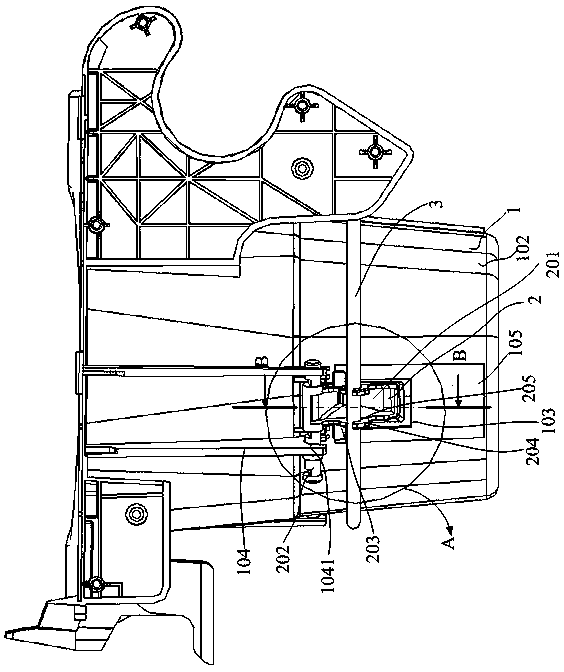

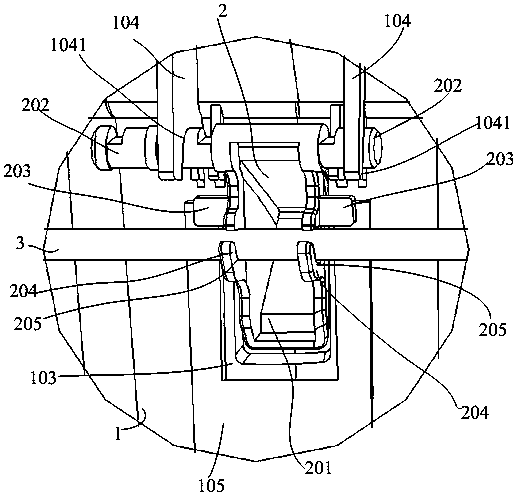

[0018] Please refer to Figure 1 to Figure 4 , an embodiment of the present invention is a cup holder for a vehicle, which includes a cup holder body 1, a cup clip 2, and an elastic rubber band 3; Two mounting holes 103 evenly distributed along its circumference, the left and right sides of each mounting hole 103 are respectively formed with first support 104; Cup clip 2 has several and is respectively arranged on the corresponding mounting hole 103, and cup clip 2 includes The splint 201, the two shafts 202 formed on the left and right sides of the upper end of the splint 201, and the baffle 203 formed on the outside of the splint 201, the splint 201 has a clamping surface 2011 protruding inward to match the cup, and each shaft 202 is respectively Rotatably mounted on the corresponding first support 104, the baffle 203 is mounte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap