Rail dragging and lifting method for rail laying

A technology of rails and rail clamps, applied in the fields of rail lifting and dragging, can solve the problems of time-consuming and labor-intensive, no identical or similar patent documents are found, etc., and achieve the effects of improving efficiency, reducing labor intensity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

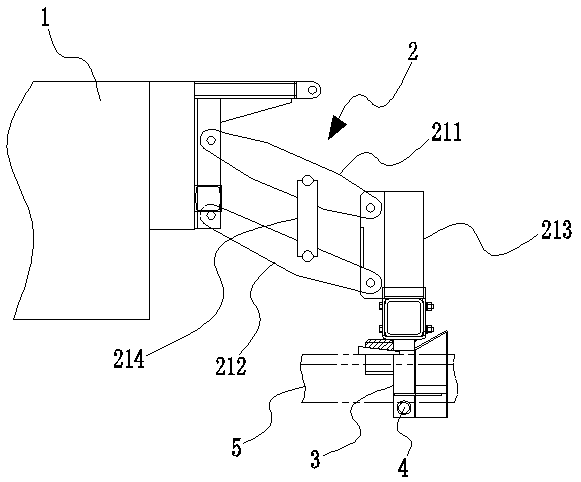

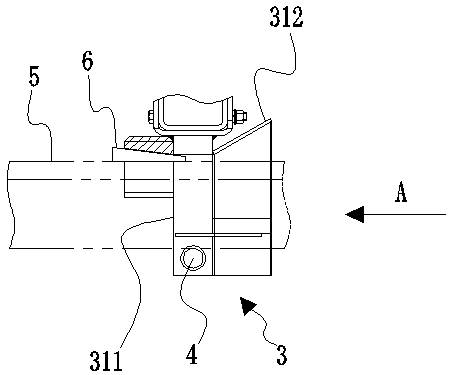

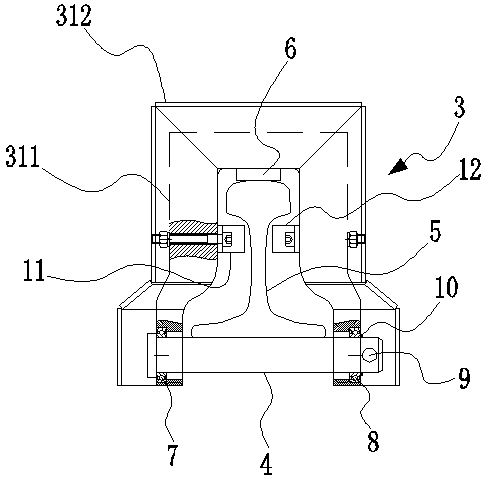

[0039] Example: such as Figure 1 to Figure 4 As shown, a method for dragging and lifting rails when laying rails, it is provided with an arm lifting device 2 on the rear end of the tractor body 1, an inverted U-shaped rail clamp 3 is arranged on the arm lifting device 2, and an inverted U-shaped rail clamp 3 is arranged on the inverted U A detachable roller 4 is provided at the bottom of the type rail clamp 3;

[0040] When dragging the rail, one end of the rail 5 is stuck in the inverted U-shaped rail clamp 3, and then the roller 4 is connected to the bottom of the inverted U-shaped rail clamp 3, and the inverted U-shaped rail clamp 3 A wedge 6 is inserted between the inner top of the rail 5 and the top of the rail 5, and one end of the rail 5 is fixed by the wedge 6, the inverted U-shaped rail clamp 3 and the roller 4, and then the tractor body 1 is controlled to move to drag The rails move along multiple rollers (not shown in the figure) placed on the roadbed;

[0041] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com