Ultrasonic detection method for austenitic stainless steel butt welding joint

A technology for austenitic stainless steel and welded joints, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, reduce greenhouse gases, and instruments. It can solve the problems of impact judgment and repair, large deviation in defect quantitative positioning, and many grass-like echoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

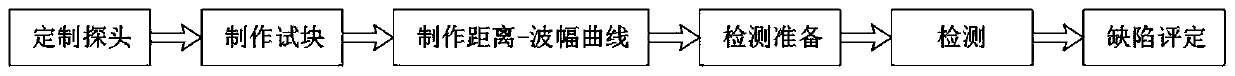

[0040] like Figure 1-10 As shown, the ultrasonic testing method of austenitic stainless steel butt welded joints includes the following steps:

[0041] Step S1, ordering probes: order several dual-crystal focusing longitudinal-wave oblique probes according to requirements. The probe data is shown in the table below. According to actual needs, 2P8×10K1, K2, 2P6×6K1, and K2 longitudinal-wave oblique probes can be used for supplementary scanning;

[0042] serial number angle of refraction Nominal frequency (MHz) Depth of focus(mm) wafer size 1 70° 1.5、2.0、2.5 20 8×12mm 2 60° 1.5、2.0、2.5 20 8×12mm 3 45° 1.5、2.0、2.5 20 10×12mm 4 45° 1.5、2.0、2.5 40 10×12mm

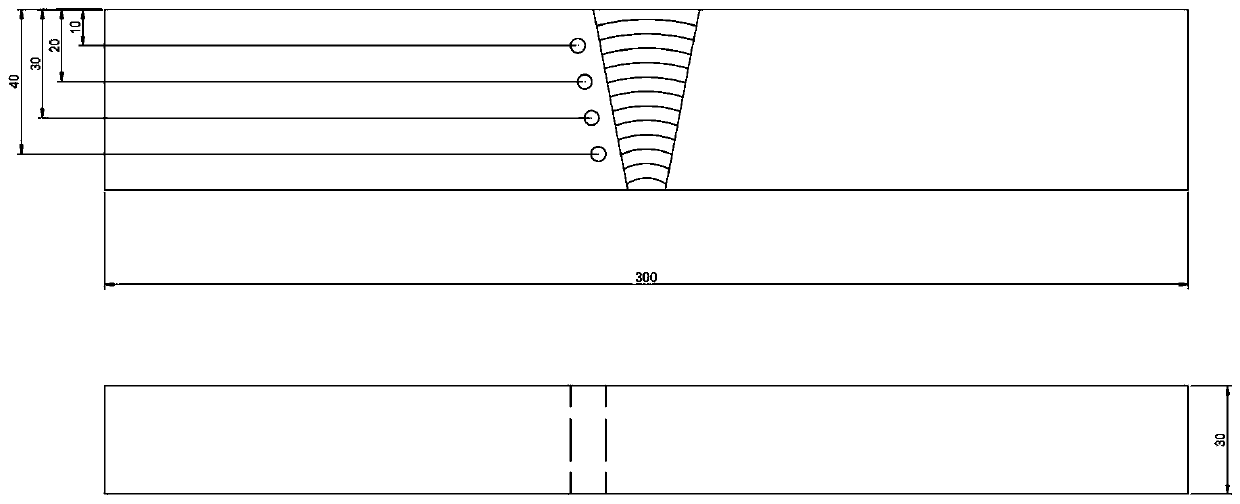

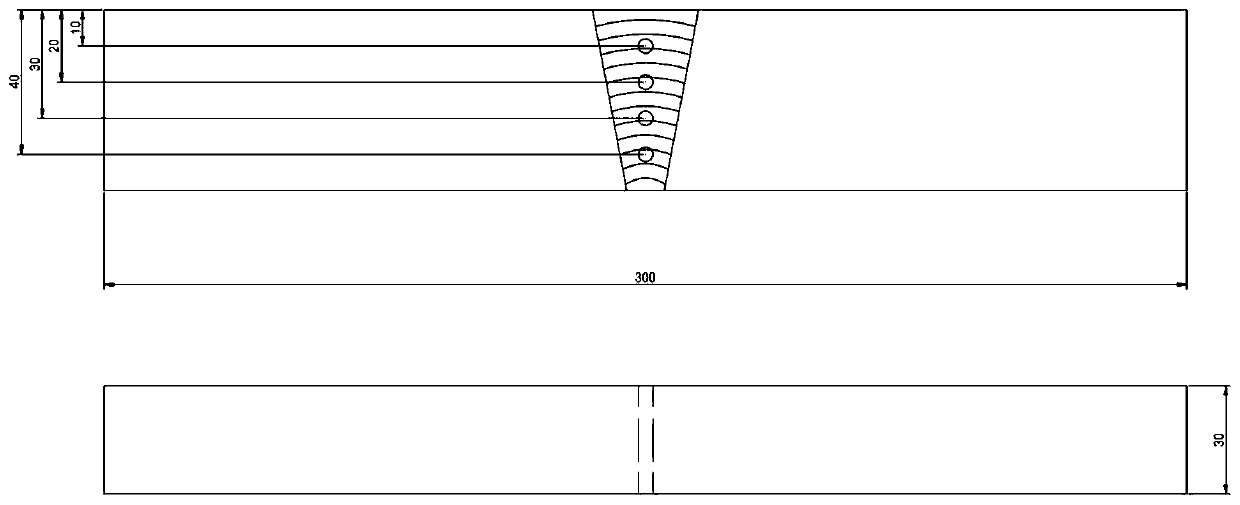

[0043] Step S2, make test block:

[0044] 1) Use the same specifications and materials as the test piece to make a special comparison test block for austenitic pipeline weld inspection. The comparison test block includes A-type comparison test block and B-type compariso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com